Process Monitoring Devices for Smart Forming Manufacturing

The devices are fitted directly to the machine to record a process quality factor (PQ factor), which is displayed on the devices.

whether it be in reshaping, punching, pressing or metal

cutting - process monitoring is the key to an optimised production. Process monitoring helps the worker in every phase: from the fitting of the machine to the observation of the production process to the quick stop in case of the threat of damage to

the machine.

Any influencing quantities affecting the machine (or the process) will in the end be seen in the process quality. Thus, the process is affected by changes in the machines, in the tool, the environment (temperature), etc. Only if this process has defined courses, will the product quality meet the requirements. Intentional or accidental changes to these influencing quantities will have an effect on the

process quality.

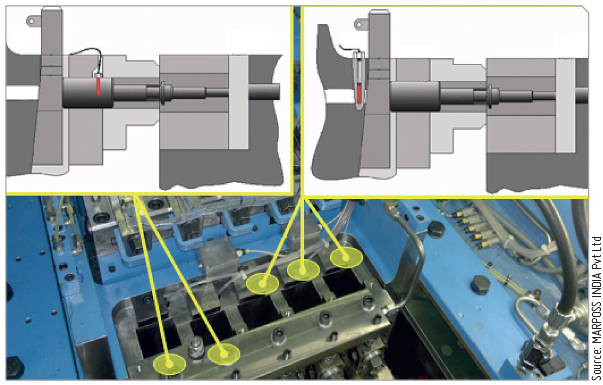

Process monitoring with BRANKAMP sensors

By means of sensor technology, recording the course of the process between the tool and the work piece, the worker is able to watch the process purposefully. The relevant quantity will, in the following, be described as the PQ (process quality) factor. The more sensitive the sensor technology and the more intelligent the measuring parts are, the better and more “accurate” is the

PQ factor.

In addition, the worker will, in the course of time, learn to assess the PQ factor correctly. The standard display shows the current process factor, the highest PQ factor thus far, and a limit set by him. He can then draw the appropriate conclusions from observing any changes and intervene or optimise.

Marposs offers BRANKAMP process monitoring devices that are fitted directly to the machine to record a PQ factor, which is displayed on the devices.

To monitor a process, certain limits need to be set, with the process monitoring device basically initiating a warning or a stop.

Displaying suitable factors for the process provides the worker with considerable advantages with respect to the optimisation of the process and the ability to influence the costs. With the PQ factor, the worker, for the first time, has an objective measured variable by means of which he is able to assess the process quality.

Benefits for implementing Process Monitoring include:

- Machine and tool protection

- In-process quality control

- Increased productivity due to extended run-time, reduced downtime and stroke optimization

- Minimized tool and scrap costs

- Process optimization for more stable processes

- FactoryNet 4.0 interface to the MES / ERP interface.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe