It's All About Having the Right Tools

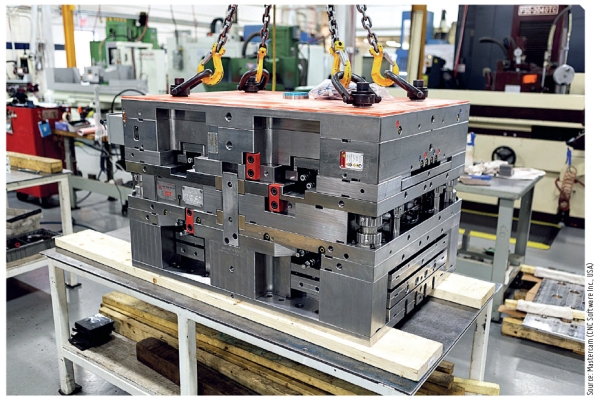

Advanced CAM techniques help Cap-Thin Molds reduce moulding cycles and tool lead times.

Cap-Thin Molds, a manufacturer of precision, multi-cavity tools for caps and closures, has a unique value proposition. The company will guarantee cycle times and if the tools do not perform accordingly, Cap-Thin will return the customer’s money.

Carmen Goudey, Manager of CNC Operations, Cap-Thin Molds, explained that customers sometimes resist the idea of paying a few thousand dollars more for Cap-Thin’s high-precision tooling, but once the tools start producing, it’s a different story. He recalls the reaction of a new customer that started using a 12-cavity tool guaranteed to deliver an eight-second cycle. The previous mould, that was in nearly-continuous use for five years, had a 12-second cycle. The customer was absolutely amazed at the productive capacity that had been gained. The extra cost of the tool was recovered almost immediately.

Cycle times, lead times challenges

While cycle times are no problem for Cap-Thin’s customers, lead times were. Cap-Thin came into being in 2013 as the result of a  merger between two highly regarded tool makers that wanted to grow its infrastructure in order to satisfy customer requests for more tooling and shorter lead times. At the time of the merger, lead times for 32-cavity moulds were 18-20 weeks.

merger between two highly regarded tool makers that wanted to grow its infrastructure in order to satisfy customer requests for more tooling and shorter lead times. At the time of the merger, lead times for 32-cavity moulds were 18-20 weeks.

Today, the manufacturing operations are consolidated within a new, larger facility and lead times for a 32-cavity mould have been driven down to 8-10 weeks. Goudey said that much of lead time improvements could be credited to the company’s reliance on 4-axis high speed machining centers and advanced computer aided software - Mastercam CAM software from CNC Software, Inc., Tolland, CT.

Bench free machining

In the CNC shop, there are typically 15 to 20 projects going on at any one time. Each machinist programs, sets up, and operates his own machine. Each CNC machine has a computer with its own seat of Mastercam installed on it. The company has a little more than a dozen seats of Mastercam and anticipates installing additional seats of more modules soon.

Cap-Thin‘s programmer machinists are very experienced. They create precision CNC programs in Mastercam, based on solid models sent from the engineering department. Goudey said, “We pride ourselves on the fact that our moulds are bench free. The machine tools are very accurate and our surfaces are extremely high precision and high finish. So when the components come off the machine, everything fits like a glove. There is no hand work involved.”

“We specialize in high speed machining. The bulk of our equipment are 4-axis high speed state-of-the-art machining centers. To take full advantage of them, you need specialized software. When CNC Software came out with its 3D high speed toolpaths, it was a real game changer for us. We started out using some of the high speed toolpaths and some of the legacy. For the most part, now we can do everything we need to do with the high speed toolpaths.”

To make such intricate, high precision components, Cap-Thin’s programmer machinists typically do not rely on the “book value” when setting machining parameters. Goudey said, “We will program what we think is correct and then the tool talks to you. You can usually hear it and see by the motion of the machine if you are at risk of breaking a tool or having it pull out of the chuck or if there is a problem with evacuation. Based on what the tool is telling us, we fine-tune the feeds and speeds to what seems to be most acceptable for that particular part. Then we capture everything in a Mastercam file so that when we have to make the part again; it’s plug and play.”

High speed machining, along with reducing the number of set-ups, tool changes and secondary operations, have all played an important role in reducing lead times by almost 50 percent in many cases. However, none of these time compression strategies are viable if they in any way compromise the machining precision that ultimately contributes to cycle time reduction on the injection moulding press.

Chasing tenths

Goudey said, “We are chasing tenths. That is a challenge because there are so many factors that go into maintaining accuracy. We control temperature in our shop to 1° or 2°C. All of our machines are on special vibration dampening foundations. Our cooling is tightly controlled because equipment operating at 42,000 and 30,000 rpm will generate a lot of heat and spindle growth. We just implemented on-machine gauging with our spindle probes to eliminate the need to take complex components off the machine a couple times for in-process checks at the CMM.

control temperature in our shop to 1° or 2°C. All of our machines are on special vibration dampening foundations. Our cooling is tightly controlled because equipment operating at 42,000 and 30,000 rpm will generate a lot of heat and spindle growth. We just implemented on-machine gauging with our spindle probes to eliminate the need to take complex components off the machine a couple times for in-process checks at the CMM.

Cap-Thin is also increasingly relying on roughing toolpaths incorporating Mastercam’s Dynamic Motion technology to minimize cutting tool wear.

This not only reduces tool costs, but also improves manufacturing process’ accuracy and consistency.

Goudey said, “With the Dynamic toolpaths, our tooling costs are less because we are using multi-fluted carbide variable geometry end mills. We can use the flute of the end mill rather than having toolpaths where you are stepping down in small Z steps and all the wear is distributed on the bottom corners of the tool. With Dynamic, you are using a deeper depth of cut with a shallow radial depth of cut that distributes the wear over a larger portion of the tool. Our tool life is probably ten times better, evacuation is excellent, and there is less wear and tear on our machines.

Looking forward

Simply building a complex precision multi-cavity tool is not enough to ensure the reduced press cycle value proposition will actually be fulfilled. So Cap-Thin has a test facility with three injection moulding machines dedicated to verifying that moulds are production-ready when they arrive at the customer.

Another recent venture targeting value-add was a partnering effort with a moulding machine builder to develop a mould system that makes it possible to perform two-color moulding on a conventional press.

Goudey said that Cap-Thin is continually updating equipment to improve precision and break bottlenecks. Securing a steady stream of qualified workers who can understand and use these technologies effectively is a concern that is being addressed via work-study programs that Cap-Thin is involved in with two

local area colleges. “All these things involve a lot of work,” he said, “but it is something we owe our loyal customers who are rewarding us with more business.”

HIGHLIGHT 1 : Customers sometimes resist the idea of paying a few thousand dollars more for Cap-Thin’s high-precision tooling, but once the tools start producing, it’s a different story.

HIGHLIGHT 2 : “We pride ourselves on the fact that our moulds are bench free. The machine tools are very accurate and our surfaces are extremely high precision and high finish. So when the components come off the machine, everything fits like a glove. There is no hand work involved.”

Source: Mastercam

(CNC Software Inc., USA)

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe