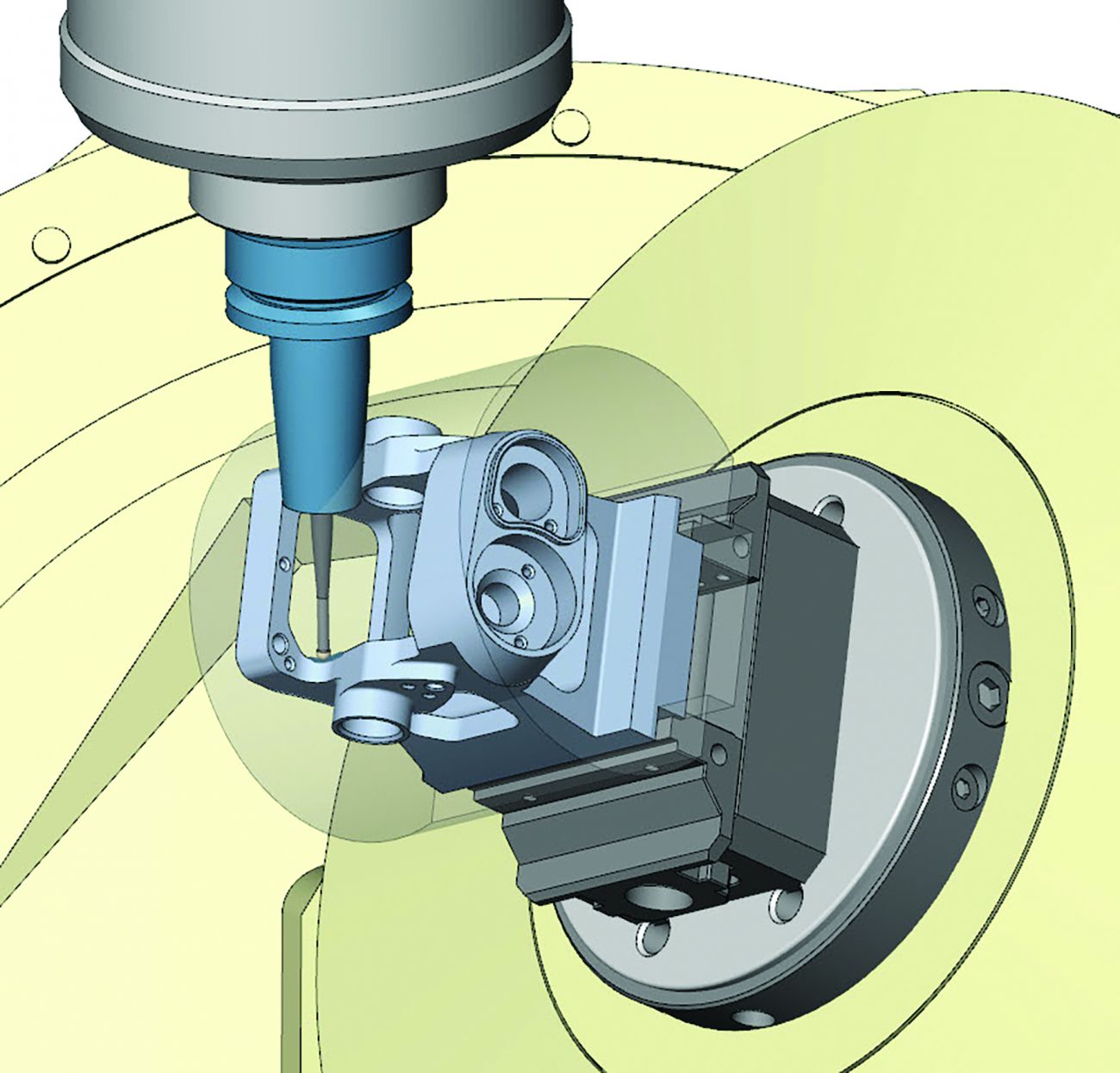

Mastercam Multiaxis Machining Increases Productivity

Tolland, US – Mastercam Multiaxis is an add-on for Mastercam Mill 3D, Router 3D, Mill-Turn, and Mastercam for SOLIDWORKS®, in line with the fact that multiaxis machining can significantly increase a shop’s competitiveness. It boosts productivity by enabling simultaneous 4- and 5-axis machining in Mastercam. Mastercam Multiaxis provides a comprehensive set of multiaxis machining strategies, both basic and advanced. These toolpaths are also useful for advanced 3-axis machine control.

The new Multiaxis Unified toolpath allows the user to generate the toolpath pattern from multiple pieces of input geometry. The toolpath selects the best algorithm to calculate the path based on the geometry choices. This single toolpath provides access to all surface-based toolpath options as well as geodesic toolpath options in a single interface.

A new Deburr toolpath enhancement is the Number of cuts along edges, which allows users to add multiple cuts to the Deburr toolpath, rounding or flattening edges, to create a quality edge on deburred parts. Additionally, when the machining type is set to 5-axis (simultaneous) or 3+2 axis, the new Tilt Range options allow users to limit tilt.

Maintaining climb and conventional machining is crucial for surface finish and tool life. Controlling Climb and Conventional Cutting now allows for control of climb or conventional cutting while working with surfaces that may require using both sides of a tool. Previously, it was impossible to do so while cutting a curved shape that required the use of both sides of the tool.

Swarf Milling toolpath enhancements include the Drop tool to floor option, which controls whether Mastercam drops the toolpath down to a floor or retracts to the bottom of swarf surfaces. The new Sorting Spiral Multi Cuts option outputs multiple slices as a spiral rather than single slices, resulting in a better finish across the part.

Rotary Advanced toolpath enhancements include the Axis offset option, which allows users to shift the tool off-center to maintain a better contact point, extending tool life and improving machining quality. The new Smoothing options use a perfect stepover to round sharp corners.

Rotary Advanced toolpath enhancements include the Axis offset option, which allows users to shift the tool off-center to maintain a better contact point, extending tool life and improving machining quality. The new Smoothing options use a perfect stepover to round sharp corners.

Mastercam Simulator, which includes the new Smart Measure feature that allows the user to measure distances quickly and accurately in the graphics window during simulation, continues to expand the critical machine simulation required for optimal multiaxis programming. Simulator now performs standard 3-axis and 5-axis operations faster when backplotting, verifying, or simulating, and the new Report pane now displays all collisions, proximity alerts, and axis overruns.

Additional improvements to Mastercam Multiaxis include:

- Maintaining a single tool axis orientation with Accelerated Finishing tools, providing optimal tool axis control to minimize or eliminate extra multiaxis movement.

- The new Point tool to rotary axis option allows the user to rotate a toolpath around an offset point instead of the toolpath being fixed to the axis itself, resulting in a better tool contact point.

- The new Automatic arc lead-in type generates automatic arcs in locations where determining the correct arc to fit can be difficult, and it makes it easier to add arcs to linking moves.

- New Apply filtering for conversion produces a more efficient toolpath by filtering incoming toolpaths to reduce size and noise.

Image Source: CNC Software Inc

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe