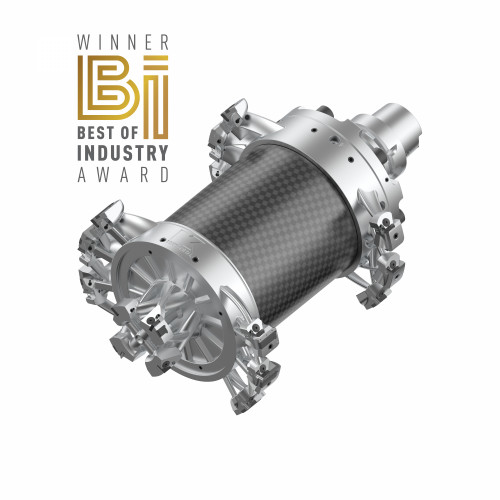

Kennametal’s 3D Printed Stator Bore Tool Ensures Fast Tool Changes and Spin-up on Machining Centers

Pittsburgh, US and Bengaluru, India – Kennametal Inc, has unveiled its next generation 3D printed stator bore tool for machining aluminum engine housings for electric vehicles. This latest version of the tool has a redesigned arm structure, a larger carbon fiber center tube, and a weight reduction of more than 20 percent over the original design. The complex tool can machine three large diameters in a single operation, saving automotive component manufacturers’ set-up time and delivering the highest accuracy and surface quality.

The stator bore tool ensures the alignment and concentricity of the machined surfaces while greatly lowering cycle time by machining three diameters in one operation. Even on less powerful machines, the lightweight 3D-printed combination tool allows for faster tool change and spin-up. Surface standards and component tolerances are met without limitations.

|

|

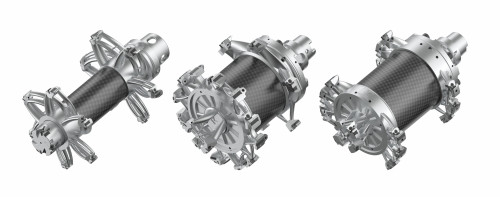

| The airfoil shaped arms with through coolant and RIQ reaming technology. Complex internal and external features enabled by additive manufacturing | First-generation design (9.5kg) on the left, and latest tool design variants (less than 8kg) on the right for hassle free tool changing |

Airfoil-shaped arms with through coolant features allow precise and powerful coolant supply to the cutting edges and guide pads, ensuring hassle-free chip removal. Traditional manufacturing would make this difficult or impossible to produce affordably, but 3D printing allows the user to achieve even such complicated internal characteristics. Furthermore, the Kennametal RIQ reaming system features easy diameter adjustment and trouble-free insert setup.

Ingo Grillenberger, Product Manager, Kennametal, said, “As our automotive customers expand their offerings of hybrid and electric vehicles, we continue to respond to their need for lighter weight tooling solutions. By leveraging advanced manufacturing techniques like 3D printing, we’ve reduced weight a further 20 percent over the first-generation tool, while improving chip control and increasing tool rigidity—innovations that help our customers machine faster and more efficiently.”

Image Source: Kennametal Inc

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe