Star Cutter and Garr Tool Develop Innovative Multi-process CNC Machine Tools

Teufen, Switzerland and Michigan, US – Star Cutter Company, a manufacturer of carbide and preforms, and Garr Tool, the USA’s leading manufacturer of high-performance solid carbide cutting tools, have collaborated to develop an innovative 5-axis CNC machine tool that completely automates the production of complex profile end mills—from blank to finished tool.

Garr Tool makes extensive use of CNC automation, including Ulmer Werkzeugschleiftechnik (UWS) and Star-Cutter tool grinding machines. All of these machines rely on control technology supplied by the CNC specialist NUM. Since 1998, Star Cutter has partnered with NUM on the development of application-specific CNC hardware and software, and it now bases nearly all of its machine tools on NUM’s open-architecture Flexium+ CNC platform. “We use NUM’s NUMROTO software for tool production and reconditioning on all of our Star and UWS machines,” says John Leppien II, Vice President of Garr Tool. “Our operators regard it as very flexible and user-friendly, and we find that it encourages interdepartmental knowledge sharing and also helps to reduce our training overheads.”

|

Garr Tool specialises in solid carbide cutting tools, including end mills, drills, reamers, and routers. |

Garr Tool began producing a series of large diameter tools for use on high-torque machines used in the aerospace industry a few years ago. However, manufacturing the tools required multiple machines and multiple processes. Therefore, the company collaborated with Star Cutter’s Elk Rapids Engineering team to develop a multi-process machine capable of handling the entire production task. As a result, in 2018, a Star CNC Tool grinder with NUMROTO end mill software, cylindrical grind, linear motors and drives, and all 5 axes on a closed loop chiller/coolant system was developed. Garr Tool is able to maintain .001” in diameter on the OD of these tools during lights out for 48-hour unattended runs thanks to this thermally stable machine.

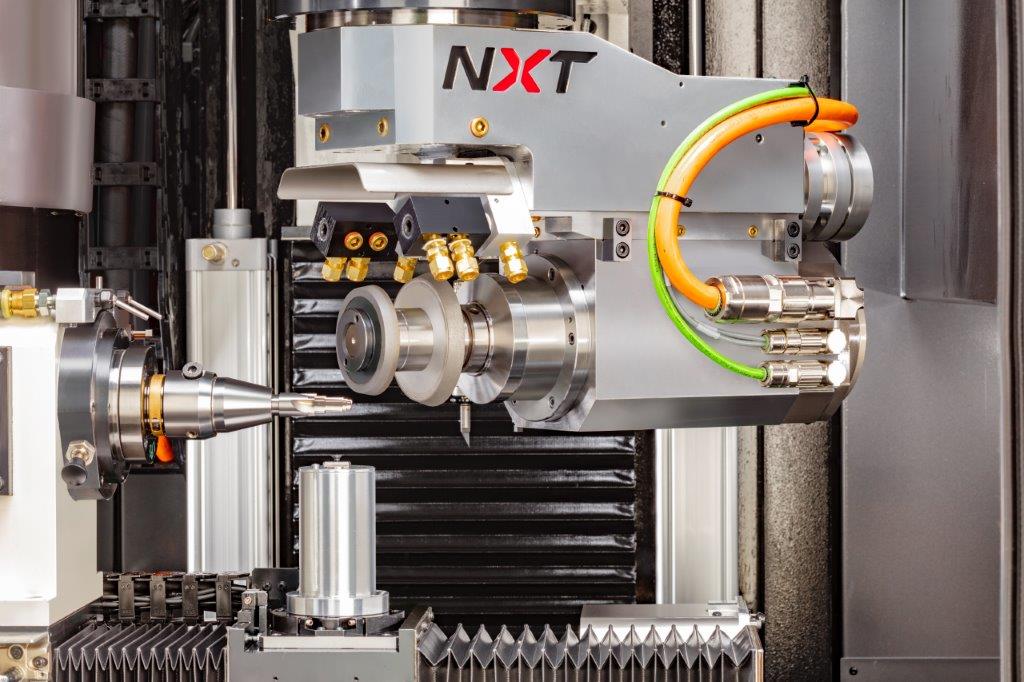

The NXT tool and cutter grinder from Star now include the same features that were introduced to Garr Tool. This new 5-axis machine tool, which is based on NUM’s Flexium+ CNC system and NUMROTO software, has linear motors instead of ball screws on the X, Y, and Z axes; direct drive torque motors on the B and C rotary axes; and a liquid-cooled spindle motor. To best suit application needs, three different types of spindle motors are available, including a very high-speed unit capable of 24,000 rpm and a very high-power unit rated at 28 kW.

The NXT has a small footprint (including the spindle/axis chiller) of 2,300 x 2,032 mm (7’ 6’’ x 6’ 6”) and an installed height of 2,284 mm (7’ 5”). These dimensions mean that the machine can easily fit on the shop floor, where space is often limited. The machine’s base is cast in Zanite® Plus polymer composite, which ensures mechanical rigidity and thermal stability.

Despite its small size, the NXT has a large grind zone, with maximum X, Y, and Z travels of 500 mm, 650 mm, and 750 mm (19.7”, 25.6” and 29.5”). The machine can handle up to 381 mm (15”) end work and up to 254 mm (10”) diameter parts. With up to 203 mm (8”) diameter wheels, automated wheel changing and probing is standard, and the NXT can also run up to 254 mm (10”) diameter wheels with coolant manifolds and up to 305 mm (12”) diameter wheels without. The ability to use large diameter grinding wheels for profiling applications or small, sub 25 mm (1”) diameter wheels for PCD pocket grinding on the same machine adds a remarkable level of production flexibility.

The new NXT tool and cutter grinder from Star Cutter includes a fully integrated Fanuc 200iD compact 6-axis short-arm robot for fully automated processing of round and flat tool blanks; the standard gripper can handle blanks ranging from 5–32 mm, with other options available. The in-process measurement data is directly fed into the CNC system’s NUMROTO software, which provides adaptive real-time control of the entire grinding process.

The NXT is based on a modular architecture and is intended to be easily integrated with other forms of industrial automation and handling robots. A traveling W-axis and a 12,000 rpm wheel dresser are among the many factory-built and retrofit options. Aaron Remsing, Jr Sales Manager, Star Cutter’s Elk Rapids Engineering Division, which is in charge of the well-known Star brand of CNC tool and cutter grinders, points out, “We believe that the NXT is the smallest and most capable CNC tool and cutter grinder on the market. Even though it is an evolutionary design, its performance is nothing short of revolutionary.”

Image Source: NUM AG

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe