Pepperl+Fuchs Presents Contour2D Sensor System for Monitoring Conveyor Belt Utilization

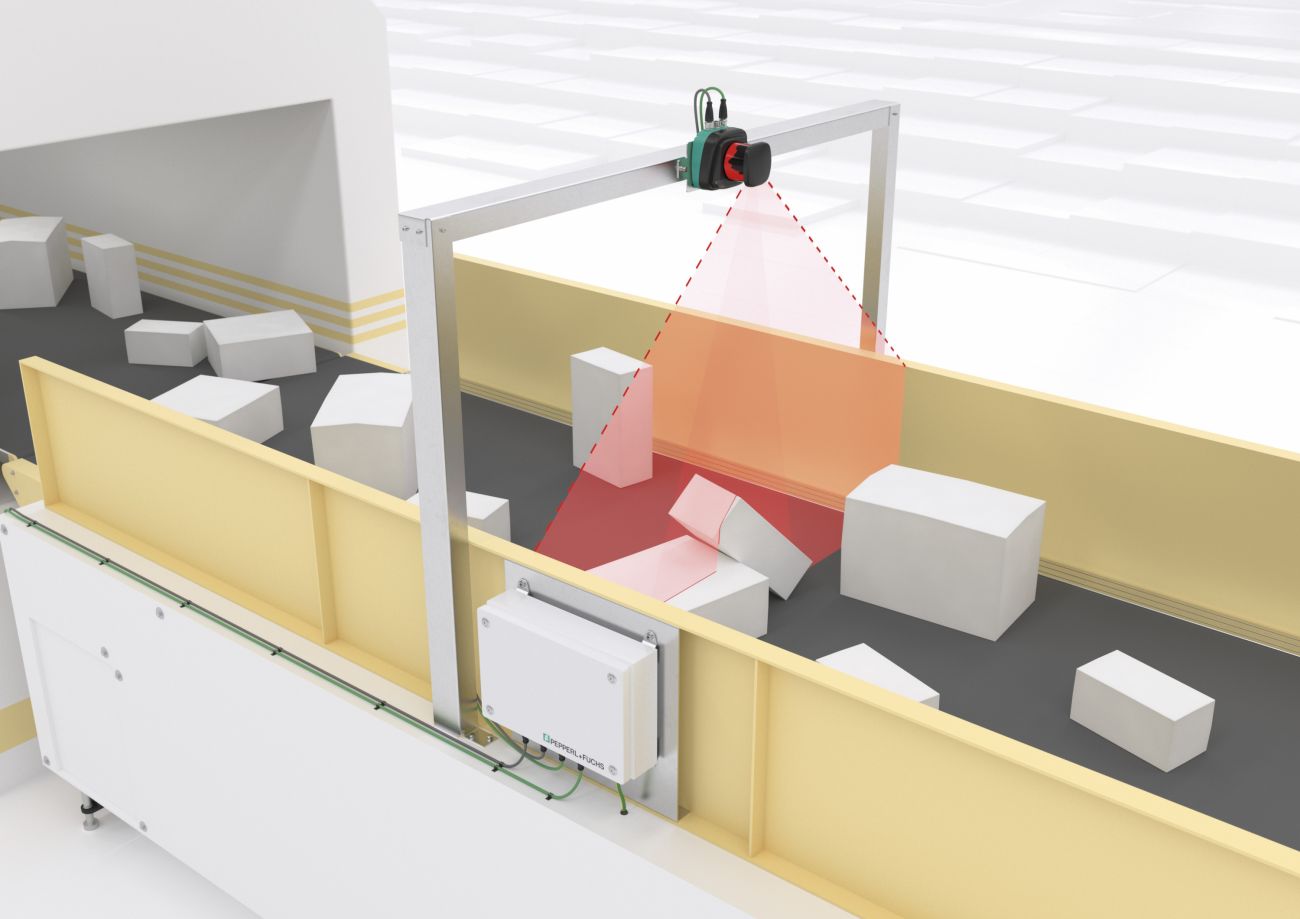

Mannheim, Germany – Pepperl+Fuchs’ Contour2D Sensor System for Monitoring Conveyor Belt Utilization combines the unique performance characteristics of the R2000 LiDAR sensor with an intelligent algorithm that ensures reliable shadow correction. Minimal installation effort and quick, straightforward, three-step commissioning round off this highly economical solution. To distribute packages on a conveyor belt as efficiently and evenly as possible for transport to the downstream station, the conveyor belt’s current utilization must be detected reliably.

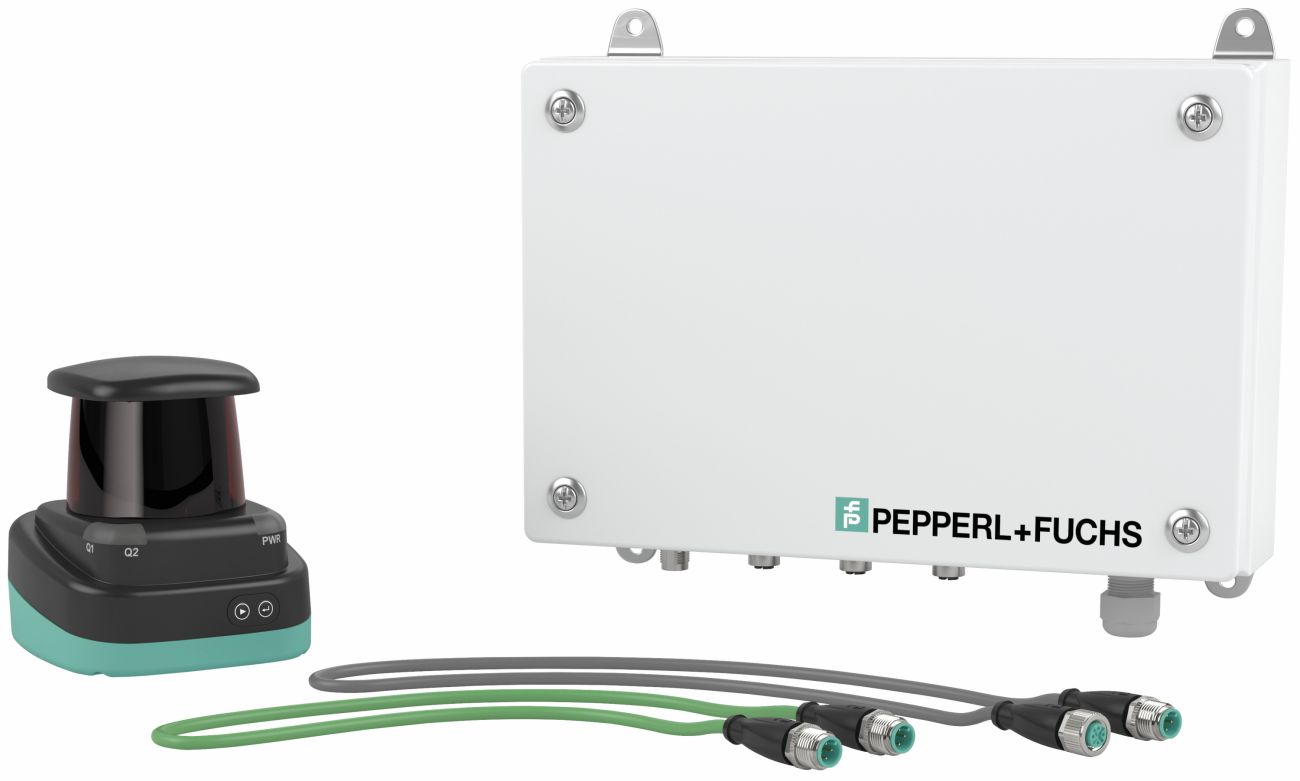

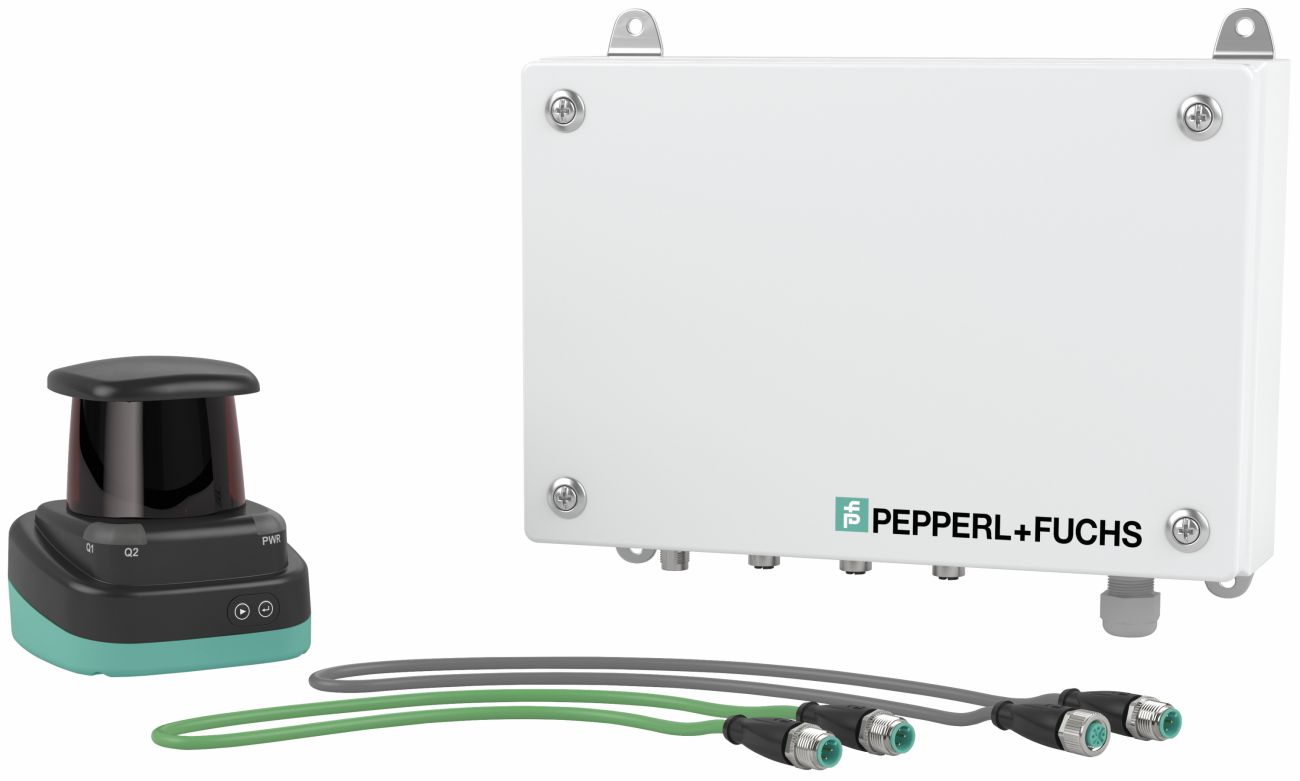

The Contour2D sensor system, which consists of a single LiDAR sensor mounted centrally above the conveyor belt, is the most efficient solution on the market. The central position of the sensor means that it detects shadows of packages on the conveyor belt, which would normally distort the system’s measurement results. However, the R2000 2-D LiDAR sensor’s high angular resolution, combined with an intelligent algorithm, makes corrections for these shadows. The Multi Scan Evaluation Unit (MSEU) of the sensor system is in charge of running the algorithm and further processing the raw data from the LiDAR sensor.

|

|

|

| Contour2D Sensor System for Monitoring Conveyor Belt Utilization |

Minimum installation effort of just two system components without major adjustments to the system - even in the retrofit. |

Since there are only two components (sensor and MSEU) to install, the Contour2D has very low hardware costs and minimal installation effort. Unlike conventional systems, there is no need for time-consuming configuration to align multiple sensors. And since only a single sensor is mounted centrally above the conveyor belt, installation requires no major conveyor belt adjustments. As a result, even existing plants can be easily retrofitted.

Image Source: Pepperl + Fuchs SE

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe