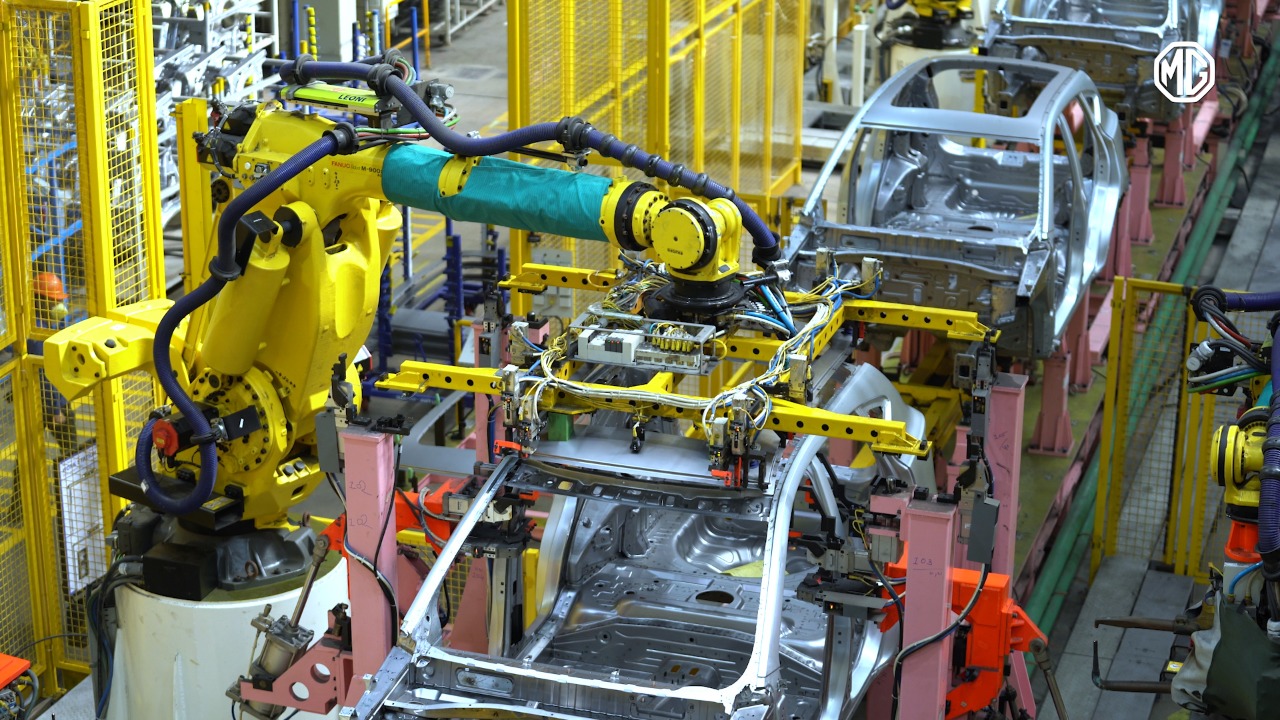

MG Motor and Siemens collaborate to develop innovative digital solutions for a Sustainable future

Gurugram, India – MG Motor India has partnered with Siemens to leverage cutting-edge digital technologies (including IoT, data analytics, Plant Simulation, and MindSphere) in its operations to increase productivity, save energy and cost, and reduce emissions and carbon footprint.

MG is the first auto OEM in the world to use MindSphere and Plant Simulation as a closed-loop digital twin. The software can connect plant assets and processes, providing insights into more streamlined paint processes, resulting in a 15 percent increase in future pre-treatment and electrocoating paint processes.

With innovation as a brand pillar, MG aims to drive change and adheres to its vision of CASE mobility. Strategic partnerships (such as with Siemens) will allow the company to lead and develop digital solutions and skills to improve productivity, save energy, reduce emissions, improve customer experience, and drive growth. In the past, the brand pioneered many segment features, including the industry's first CAAP (Car as a Platform), a unique on-demand in-car service, and a subscription-based model. The automaker recently became the world’s first to use ULTRAX Degreaser (a liquid alkaline degreasing cleaner) to reduce 787 tonnes of CO2 per year. The company also installed a 4.85 MW wind-solar power plant to power its operations in the Halol manufacturing hub, saving 2 lakh MT of CO2 over a 15-year period.

Ravi Mittal, Director-Manufacturing, MG Motor India, commented, “MG is constantly evolving to meet rapidly changing requirements and provide innovative solutions by collaborating with ecosystem partners. Our partnership with Siemens is focused on industrial digitalization and intelligent manufacturing. It will strengthen our commitment to lowering carbon footprints, increasing production efficiency, and providing significant energy and cost-saving solutions.”

Ecstatic about the alliance, Suprakash Chaudhuri, Head-Digital Industries, Siemens Limited, said, “What we have created with MG Motor is the digital twin of production. It allows MG to connect to the plant through automation and monitor real-time operational performance. This generates valuable insights by applying advanced analytics to real-time data in a closed-loop simulation environment. The seamless combination of the Real and the Digital world sets the basis for continuous improvement. We are looking forward to our partnership with MG and supporting them in achieving their future goals.”

Image Source: MG Motor India

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe