Optimate GmbH to Present its New Feasibility and Potential Recognition App at EuroBLECH 2022

Stuttgart, Germany – Optimate GmbH, sheet metal parts optimization expert and independent start-up of the high-tech company TRUMPF, will showcase its App of the same name at EuroBLECH, in a new design and with expanded functionalities. In Hannover, the new version of the Optimate App will be introduced to a large professional audience for the first time. Visitors will be able to test its many benefits for themselves at booth B70 / B94 in Hall 11 (at TRUMPF).

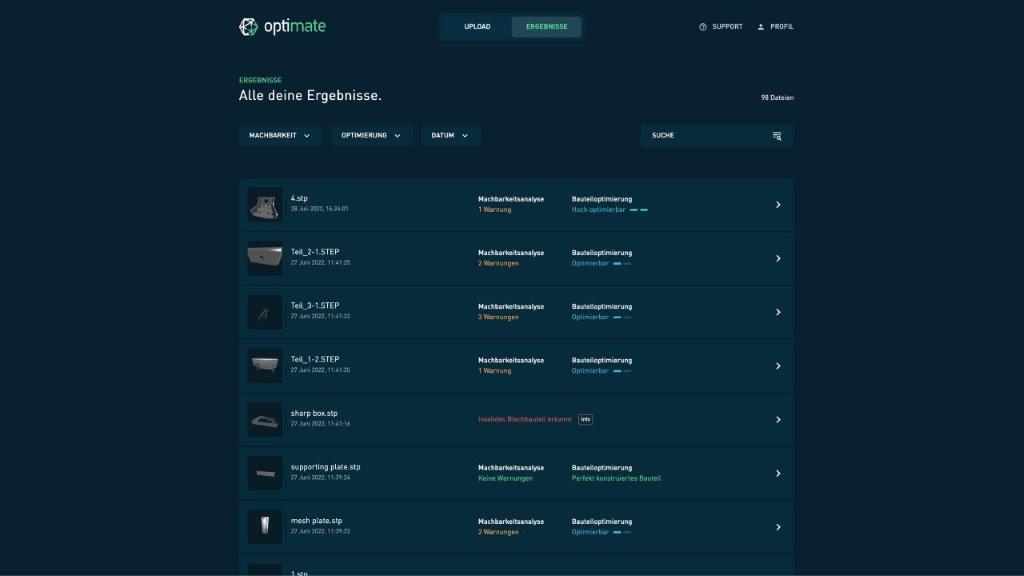

In the future, Optimate will play a critical role in the digitalization process related to Industry 4.0. In addition to feasibility analysis, the cloud-based Optimate App’s digital features for sheet metal processing include powerful, AI-based potential recognition - and optionally offer automated part optimization with integrated redesign. “If all you need is the feasibility analysis to detect and eliminate design warnings, our basic package is entirely sufficient,” says Jonas Steiling, CEO, Optimate.

Following the design warning analysis, the designer can improve the bending part to the point where it can be finished on bending machines as well. The App already displays and describes the bending part’s potential to the user. The potential recognition indicates whether or not a part can be optimized and, if so, to what extent: optimizable or highly optimizable. The user can then choose whether or not to take advantage of this potential. In the future, they will be able to access the App upgrade with integrated and automated part optimization with a single click.

“In the case of highly optimizable sheet metal parts with a potential cost saving of up to 40 percent, it may be worth taking a closer look and thinking about an upgrade,” explains Steiling. “Depending on the batch size, it may be possible to benefit from huge cost savings, for example by reducing material or even eliminating entire work steps.”

The App has been made more user-friendly to make it easier for users to get started. It is now accessible via direct upload. Whereas in the previous App, feasibility analysis and part optimization could be chosen separately, they are now combined. The first step is to upload a part, which is then real-time analyzed. As a result, design warnings and optimization potential are displayed. The App provides users with easy access to the entire Optimate expertise from the sheet metal working industry.

“We are planning extensive live demos at our booth at the EuroBLECH and are looking forward to welcoming visitors and to many compelling discussions about the new functions of our Optimate App,” insists Steiling.

Image Source: Optimate GmbH

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe