TRUMPF to Launch New Solution to Improve Laser Welding Quality & Robustness at EuroBLECH 2022

Ditzingen, Germany – TRUMPF will introduce a new solution to improve the quality and robustness of laser welding at EuroBLECH 2022. The welding robot is currently the only way to guide the laser beam during the welding process; however, the company’s new BrightLine Scan technology will allow users to guide the laser beam using the laser scanner.

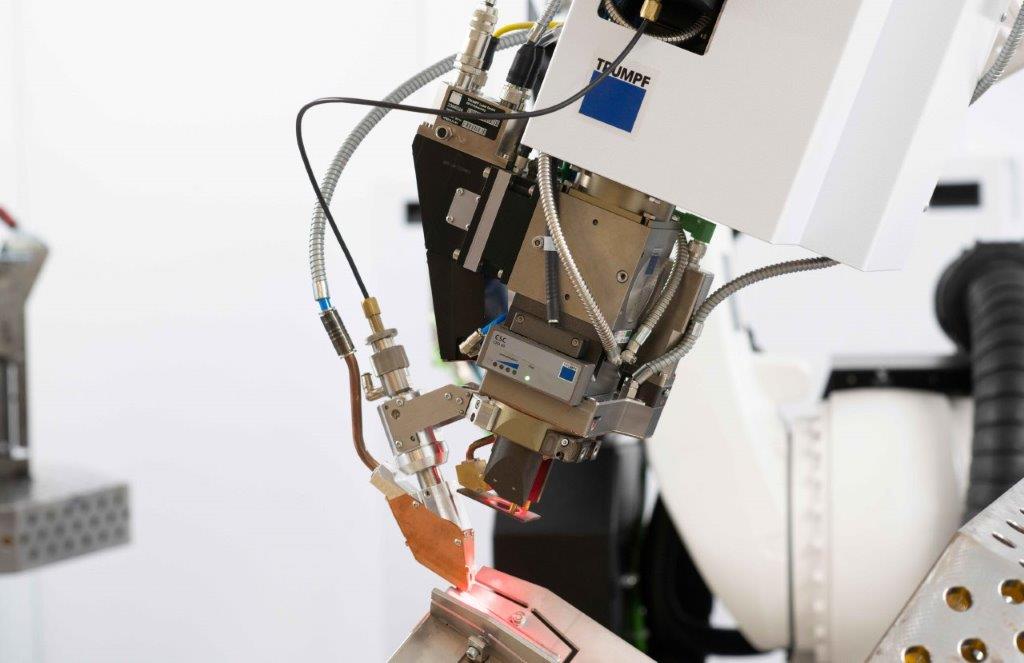

This robot-scanner combination allows the robot’s forward motion to be supplemented by a further, freely programmable movement of the laser in any desired direction. The use of specially developed lightweight mirrors aids in this ‘oscillating motion’. This new technique doubles the thickness of sheets that can be processed in heat conduction welding by enabling scan frequencies in the kilohertz range, increasing it from three to six millimeters. The new technology allows users to customize the bonding surfaces of the parts, which are melted directly by the laser beam, to suit each application. This results in a more reliable process and higher quality parts.

The fact that the beam can now also be guided using the scanner also makes it easier to achieve tighter tolerances. “BrightLine Scan is another example of TRUMPF’s determination to offer industry-relevant solutions by focusing on the needs of sheet-metal fabricators,” says Martin Geiger, Product Manager, TRUMPF. “Companies can enjoy huge benefits by incorporating this technology in their day-to-day work, because tighter tolerances in the welding process mean less scrap, faster processing, and lower costs.”

The new BrightLine Scan technology for TRUMPF’s TruLaser Weld 5000 laser welding machine will be introduced at EuroBLECH.

|

The BrightLine Scan technology enables the laser’s focusing optics to be freely programmed |

Dual method of guiding laser beam

The task of guiding the laser beam through the laser scanner in BrightLine Scan is performed by the freely programmable PFO 20 focusing optics. TRUMPF engineers created these, which are integrated into the robot’s welding optics. The use of a robot and scanner to guide the beam increases the robustness and flexibility of the laser welding process significantly. “Previously, we had to position the laser beam right over the seam to guarantee a high-quality weld. If you deviated from the right spot by a millimeter, or even less, the part often had to be scrapped,” explains Geiger. “But now that the beam can also be guided via the scanner, it’s easier to achieve tighter tolerances. That makes it possible to correct any minor inaccuracies that creep in during previous steps, such as bending.”

Easy to program and use

BrightLine Scan is seamlessly integrated into the welding optics of the robot, making programming the TRUMPF welding cell as quick and simple as ever. The company offers TechSets, which contain all of the parameters required for common applications. Fabricators can also use BrightLine Scan in the TruTops Weld offline programming system in the welding cell. This enables users to program the machine while it is welding another part.

The new technology offers a reliable solution for welding sheets up to six millimeters thick, making it ideal for agricultural and construction machinery. The high precision and quality of the seams also make it a good choice for manufacturing furniture products and EV battery trays. BrightLine Scan is also an excellent choice for making electrical cabinets.

“Offline programming is a fast and economical solution for both low and high production volume,” reiterates Geiger. “And the ability to store all the basic process information directly on the machine gives us the buffer we need to deal with the shortage of skilled workers.”

Image Source: TRUMPF SE + Co KG

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe