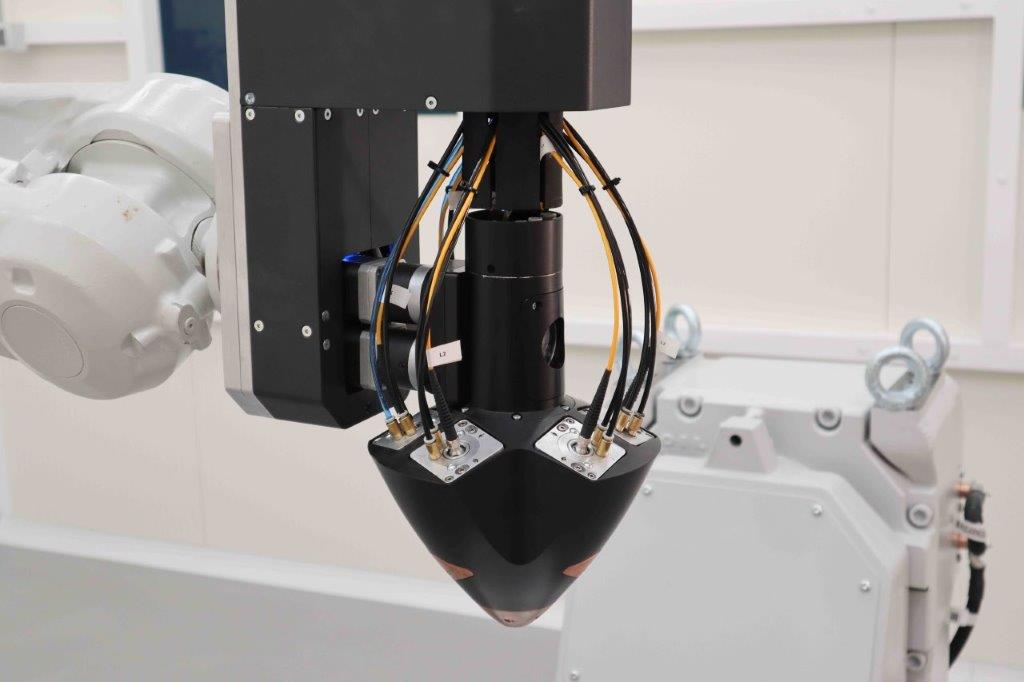

Meltio Partners with 12 Software Companies to Foster Hybrid & Robotic Additive Manufacturing Adoption

Linares, Spain – Meltio, a manufacturer of disruptive laser metal deposition technology, recently introduced its new Meltio Engine Software Partners ecosystem to ensure, through this partnership, a set of guaranteed and reliable software solutions for customers to identify the best software solution to use Meltio Engine CNC Integration and Meltio Engine Robot Integration. It enables it to complement its Meltio Horizon to give the most end-to-end additive manufacturing software solution set in the industry by bringing together the leading software vendors in the additive manufacturing business. The multinational wire-laser metal 3D printing technology manufacturer developed 14 evaluation points, 9 of which concern toolpath strategy, and provides a comprehensive software ecosystem to suit a wide range of customer needs through this partnership.

The following are the 12 most innovative additive manufacturing (AM) software companies from around the world that have joined Meltio Engine’s Software Partner ecosystem for hybrid and robotic platforms: SKM DCAM from SKM Informatik; AdaOne from Adaxis; AiSync from AiBuild; Esprit from Hexagon; Fusion 360 from Autodesk; Aplus+Mastercam from Camufacturing and Mastercam; Hypermill from OpenMind; SiemensNX from Siemens; Hy5CAM from 1ATechnologies; RobotStudio 3D Printing PowerPack from ABB; and SprutCAM X from SprutCam.

|

|

Meltio provides an open platform for hardware (any robot or CNC) as well as software, allowing the use of any software to manufacture metal parts and meet the market’s growing demand for hybrid and robotic additive manufacturing processes. It is critical to provide a great user experience, so the company has created a process for technically validating each solution, avoiding extra work between the final customer and each software provider, such as defining post-processors or ensuring the specific software can get the most out of the Meltio Engine, such as the ability to use two materials in the same part (Dual-Wire). Meltio’s engineers have researched the technological requirements for developing slicing solutions for the bulk of the parts required by the industry. They established nine levels of complexity, including example geometries that help buyers and developers grasp the diversity of parts.

Through advanced slicing features such as fixed tool orientation, revolved surfaces, features on non-planar surfaces, simple surface coating, radial cladding, 360-degree features, variable layer deposition, controlled area repair, and non-controlled area repair, this new software ecosystem offers to the market tools to address a wide range of parts and industries.

The company takes another step ahead in its commitment to enhance the ease of use of its wire laser metal 3D printing technology by making this software platform available to its industrial customers. It takes another step ahead in its firm commitment to provide a 360° solution for the ease of use of its wire laser metal 3D printing technology in software and hardware with the launch of this new ecosystem. The company’s end-user value is built on its ability to provide freedom of choice and healthy competition in a new market.

Ángel Llavero, CEO, Meltio, explains, “For a year we have been working with all of them, sharing the needs that we understood to be most suitable for our customers, going as far as sharing as well as, in some cases, sharing the mathematical algorithms needed for the functionalities we required. The result of this collaboration between our engineers and the teams of these companies has now resulted in offering this software platform to the market.”

“With this alliance, Meltio sends the message to all our customers of the Meltio Engine CNC and Robot Integration that the software that appears is tested and certified for the handling and proper use of Meltio’s technology,” he further reiterates. “With the creation of this new agreement with major software development companies, we continue our strategic goal of facilitating and democratizing metal additive manufacturing. Ease of use and technology are key for us. Meltio’s industrial customers are guaranteed that any software program can have a guaranteed user experience.”

Image Source: Meltio

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe