Future Trends To Watch Out

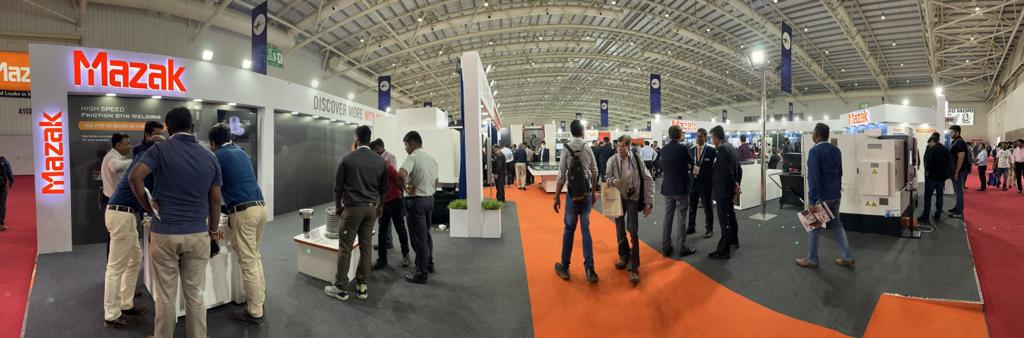

The recently concluded IMTEX 2023 offered the participants the Digital Manufacturing Pavilion as a dedicated space to explore the latest smart technologies. Industry stakeholders highlighted notable developments in the Indian manufacturing landscape, as well as their innovative solutions to meet current and future demands. Let’s take a closer look at what caught their attention.

Digital manufacturing has been gaining momentum in the Indian Manufacturing sector in recent years. It refers to the use of advanced digital technologies such as IoT, AI, robotics, and cloud computing to optimize the manufacturing process, increase productivity, and reduce costs. The implementation of digital manufacturing techniques can help Indian manufacturers enhance their competitiveness and meet the demands of an increasingly globalized market. The Indian Government has also launched various initiatives to promote the adoption of digital manufacturing, such as the ‘Make in India’ campaign and the National Policy for Advanced Manufacturing.

|

|

|

Team Airtech Pvt Ltd |

Team Andreas Maier Workholding Technology Pvt Ltd |

IMTMA, at the recently held IMTEX 2023 & Tooltech 2023 and Digital Manufacturing 2023, assumed responsibility for showcasing digital innovations, educating Indian manufacturing participants on their advantages, and encouraging their adoption. The shift towards digitalization, as observed by the participants, has already begun. The Association spared none of its efforts in ensuring that it plays the part of the catalyst in the process.

Measuring success

Anil Gupta, Managing Director, APM Technologies 3D Pvt Ltd, observed a noticeable trend towards Industry 4.0 and digital manufacturing among the newly launched products. APM Technologies, being a metrology company, can affirm that its measuring products are aligning with this shift towards digitalization in the industry.

“Our booth received a majority of visitors from the Automotive industry who were interested in purchasing 3D Scanning and 3D Printing technology. We demonstrated our powerful 3D scanner, ScanBox, which measures four times faster than conventional methods. In 3D Printing, we showcased Formlabs 3L. Formlabs is known for designing end-to-end additive workflows. The Form 3L brings the Formlabs experience to large format 3D printing, in which no specialized technicians are required. It offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface,” he informs.

|

|

|

Team APM Technologies 3D Pvt Ltd |

Team Blaser Swisslube Solutions Pvt Ltd |

|

|

|

Team Chennai Metco Pvt Ltd |

Team Chiron India Machine Tools Pvt Ltd |

Vikrant Saigal, Managing Director, Airtech Pvt Ltd, a leading manufacturer of high-speed power chucks, rotary cylinders, and special work holdings for CNC lathes, believes that the exhibition has always held a special place for those in the Machine Tool industry, and the 2023 edition was no exception. “One remarkable aspect was the rapid integration of new software, hardware, and technologies like IoT, AR, VR, Smart Sensors, and Industry 4.0 into machines and their accessories. The adoption of 3D printing and other additive manufacturing technologies was also evident. Additionally, various types of machines, workholding fixtures, robots, and coolant tank systems stood out in the adoption of Industry 4.0. Smart Manufacturing could be seen in the way the machines were configured using 5th-Axis, multi-tasking turning machines, and turn-key solutions provided by OEMs, leading to improved productivity and quality. It was encouraging to witness the localization of robots and CNC control systems.”

|

"One remarkable aspect was the rapid integration of new software, hardware, and technologies like IoT, AR, VR, Smart Sensors, and Industry 4.0 into machines and their accessories. The adoption of 3D printing and other additive manufacturing technologies was also evident." |

The company’s customers are mainly split into OEMs, end-users, and dealers. “Most OEMs are very old customers, and they visited our booth at IMTEX 2023 to see our new workholding fixtures and solutions for various turning, grinding, gear-hobbing, and VMC applications. In the end-user category, we have a diverse range of customers from the Automotive industry; Oil & Gas industry; Industrial Automation; Fasteners, Pumps, and Valves manufacturers; Fans manufacturers; Turbine parts manufacturers; Steel Forgings and Castings manufacturers; Aluminium castings manufacturers; manufacturers of Material Handling equipment; various welding applications; and Aerospace, Defence, and Gear industries, and many others. The customers generally visit if they have any workholding challenge that needs to be addressed,” he adds. The company also had customers from outside of India who showed keen interest in its products.

TV Mohan, Country Head & Managing Director, Andreas Maier Workholding Technology Pvt Ltd, says IMTEX 2023 provided him an opportunity to observe numerous noteworthy advancements and progress in the Indian machine and cutting tools space, including the integration of cutting-edge technologies in machines, workhandling, and automation; the adoption of competitive pricing and reduced costs in terms of productivity and set-up times; the implementation of Industry 4.0; the utilization of AI for prototyping, virtualization, and innovation; the increase in global market share; and the development of robots, 3D manufacturing, and comprehensive manufacturing/factory solutions.

|

|

|

Team FIBRO India Precision Products Pvt Ltd |

Team Gedee Weiler Pvt Ltd |

|

|

|

Team Jyoti CNC Automation Ltd |

Team Quaker Houghton |

The company had a wide range of visitors from the Machine Tool, Fixture, Aerospace, Automotive and General Engineering industries. “Several leading manufacturers, such as LMW, BFW, Hurco, Philips, Makino, etc., had our workholding and clamping devices on their live machine displays,” he adds.

Andreas Maier’s ‘ZERO-POINT Clamping System’, which is patented around the world and has widespread adoption across all industries, was the one that garnered the most attention.

|

"IMTEX 2023 provided an opportunity to observe noteworthy advancements in the Indian machine and cutting tools space, including the integration of cutting-edge technologies in machines, workhandling, and automation and the adoption of competitive pricing and reduced costs in terms of productivity and set-up times, among other things." |

Together in customers’ success

As a leader in metalworking solutions, Blaser Swisslube’s motto has been to help customers win. The company participated in the Digital Manufacturing Pavilion at IMTEX 2023 to showcase its digital advancements and initiatives and help its customers stay competitive in the global market.

“One of our unique new initiatives is the Smart Automated Coolant Management Solution. It is a modular approach to help customers adopt digitalization and gain transparency in data points and process reliability in their machining processes,” explains Punit Gupta, Managing Director - West Asia (India & SEA), Blaser Swisslube Solutions Pvt Ltd.

|

|

|

Team Rajamane Industries Pvt Ltd |

Team S&T Engineers Pvt Ltd |

|

|

|

Team Siemens Ltd |

Team Taegutec India |

Liquid Tool Analyzer is a simulation tool that helps customers bring visibility to their machining data and establish a leverage effect on various cost drivers.

“We have the know-how and do-how in a wide range of industries, applications, and materials. We are glad that during IMTEX 2023, visitors from a variety of industry sectors, including Automotive, General Machining, Die & Mould, Aerospace, Industrial Machinery and Equipment, Medical, Tool Maker, Oil & Gas, and Aerospace, learned about Blaser offerings for their operations,” adds Gupta.

|

“The use of sensors, cameras, and Bluetooth devices is rapidly gaining ground in the manufacturing industry, enabling remote monitoring of factories. Furthermore, cloud computing of machining data contributes to enhancing overall operating efficiency.” |

With its holistic approach and profound machining knowledge, the company offers solutions that help customers

across different industries fully capitalize on the potential of their machines and tools and turn their metalworking fluid into a key success factor – a Liquid Tool.

Gap getting bridged

C Renganathan, Managing Director, Chennai Metco Pvt Ltd, noted that customers today are more interested in automated, robotic systems. What is happening in the west in advanced manufacturing is seeming to be catching up in India rather quickly. Indian manufacturing has now reached a stage where it has the need and the resources to bring digitization to the shop floor.

“We received visitors from across industries. However, most belonged to the Auto Components Manufacturing sector, which witnesses a trend of manufacturing being outsourced to India from the US and other countries. This is adding up to the global volumes in this sector,” he adds.

|

|

|

Team UCAM Pvt Ltd |

Team U-Tech Associates |

For Rajesh T Ghashi, Managing Director, Chiron India Machine Tools Pvt Ltd, it was great to witness Indian machine tool companies developing their digital solutions to cater to Industry 4.0 requirements and offering digital and smart solutions along with their machine tools. “This demonstrates the industry's commitment to innovation and staying ahead of the curve in terms of technological advancements. In addition, the development of import substitute technologies displayed at the show came across as a positive sign of India’s growing self-reliance in the Manufacturing sector,” he adds.

The company featured its Micro 5 high-speed, high-precision machining center for micro-precision parts catering to the Medical, Watch, and Jewelry industries, which has been well received in the market. “We also received prospective visitors from the same sectors at our stall, and we are already working on some projects,” he shares.

“Digital or smart manufacturing is currently the buzzword,” notes Vivek Nanivadekar, Executive Director, FIBRO India Precision Products Pvt Ltd. The Indian manufacturing sector is gradually making headway in this direction, although the progress, as he points out, is slow. “The use of sensors, cameras, and Bluetooth devices is rapidly gaining ground in the manufacturing industry, enabling remote monitoring of factories. Furthermore, cloud computing of machining data contributes to enhancing overall operating efficiency,” he adds.

“However, in my opinion, the requirements for smart manufacturing differ significantly between the western world and India, particularly when it comes to the man-machine combination,” he adds.

Most of the company’s visitors at IMTEX were from the Auto sector, followed by Defence and Automation. “The rotary tables for automation and metal cutting as 4th/5th axis displayed in the booth were the main attraction for the visitors. All these tables are made in India. They are of German quality but not at German price,” he informs.

Anjay Goliya, Vice President – Sales & Service, Gedee Weiler Pvt Ltd (GEDEE Group of Companies), could observe a growing awareness among Indian manufacturers about the benefits of digital and smart manufacturing. “The benefits are significant, such as increased efficiency, productivity, and cost savings. Many companies are investing in technologies like automation, artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT) to optimize their operations.”

“The majority of visitors, as per usual, came from the Auto sector. However, there was also a notable presence of visitors from the Aerospace, Defence, General Engineering, Agriculture, and Medical sectors. Encouragingly, visitors from all sectors were actively seeking solutions to address their common pain points, such as unskilled manpower, high costs of space, rejections, and the challenge of delivering faulty products to customers without compromising on productivity and quality,” he adds.

Almost all our machines attracted great numbers of visitors since they were Multitasking Machines. Our UT500DUO MT and UT350DUO model machines, doing Eccentric Turning and Simultaneous Machining, respectively, were of significant interest to the visitors. Our most affordable Turnmill machine model, Flexturn Neo TM, has already created ripples in the highly competitive metal cutting market.

Developing the seventh sense

At the exhibition, Jyoti CNC dedicated a special section to showcase its efforts in digitizing factories. Its Industry 4.0 initiative, 7th SENSE, played a significant role in positioning Jyoti as a leading provider of smart factory solutions. The overwhelming response from not just large corporations but also customers in the MSME sector highlights a growing interest in upgrading to modernized technologies offered by Jyoti. This encouraging response is indicative of a shift in the Manufacturing industry towards digitization. The company has observed a growing trend among young professionals who are highly inclined toward digitized manufacturing practices.

|

The overwhelming response from corporations and customers in the MSME sector is indicative of a shift in the Manufacturing industry towards digitization. Another growing trend is observed among young professionals who are highly inclined toward digitized manufacturing practices. |

At IMTEX 2023, the company displayed MX 16, a multitasking machine with a hydrostatic rotary table, which became a showstopper of the exhibition. “In addition, our newly launched machine VST 160 – a vertical shaft-turning machine; ABX 40 – a 5-axis blade machining center; and Zebra – a next-gen productivity-oriented machine also were a hit. We received tremendous response from visitors belonging to Aerospace, Die-Mould, Automobile, and General and Heavy Engineering, which are boosters for economic growth,” shares Himanshu Shaparia, President – Sales, Jyoti CNC Automation Ltd.

Ecosystem for digitalization being built

Rohit Bhale, Senior Commercial Manager, Quaker Houghton, says that IMTEX 2023 made it clear that the ecosystem is getting developed to support digitization in manufacturing. “Our industry-specific application expertise in fluids, combined with QH FLUID INTELLIGENCE™, our avant-garde Industry 4.0-ready technology, will be enablers for customers in their journey to digital transformation and smart manufacturing,” he adds.

Quaker Houghton welcomed visitors from the Aerospace industry, and Transportation industry, and Industrial Segment. The visitors from the Government sectors, in particular, Defense and Aerospace were keen to understand the latest trends in manufacturing. “Visitors were enthusiastic to learn about QH offerings in terms of Synthetic Oil and Grindaix lubricoolant delivery system, which enhances coolant life and optimizes the use of coolant with minimum wastage,” he adds.

|

| Source: Magic Wand Media |

Rajendra Rajamane, Managing Director, Rajamane Industries Pvt Ltd, felt that the demonstrated technology was of world-class caliber, as evidenced by the numerous applications showcased. “Several Indian companies showcased domestically-developed technologies at the event. Moreover, there was a significant demand for low-cost automation, which many Indian automation companies effectively demonstrated. In addition, there was a growing interest in complete project setups that encompass machines beyond cutting.”

“We had visitors mostly from the Auto and Defence sectors. Many were from PSUs. Energy saving and high efficiency

were understood as the most sought-out product features,” he adds.

T Venkatesan, Vice President, S&T Engineers Pvt Ltd, “IMTEX 2023 made it clear that the Indian Manufacturing industry is increasingly embracing advanced technologies, such as Industry 4.0 and automation, to lower labor costs and enhance productivity.”

“The event was an absolute hit with us. We received visitors from the Aerospace, Automotive, Die & Mold, and other Manufacturing sectors, as well as from Russia and the UAE,” he shares.

“Digitalization is key for Indian machine tool manufacturing to move up the value chain. With the relevant Digitalization solutions showcased by Siemens, our customers did seem to be convinced that these are essential to fill technology gaps and leverage the growth opportunities to meet their growing requirements,” says Vijay Pratap Singh, Country Business Unit Head, Motion Control, Digital Industries, Siemens Ltd.

The company had a mix of machine tool builders and users across various industries like Aerospace and Defense, Automotive, General Engineering, and Electronics. Visitors could also experience many practical use cases of benefits that Digitalization can provide by combining the real and virtual worlds. “We were pleased to see our customers finding merit in our new innovations like SINUMERIK One, solutions for Additive Manufacturing, Xcelerator, and Shopfloor management software,” adds Singh.

For L Krishnan, Managing Director, Taegutec India, Past President – IMTMA, “The visitor profile was the most inspiring aspect, with a notable diversity of industry visitors spanning from Automotive and Auto Parts to Aerospace, Defense, General Engineering, and more. This shift highlights the spread of our manufacturing investments throughout the country, which is a positive development. As a cutting tool company, we are constantly seeking innovative solutions to enhance productivity and minimize manufacturing costs.”

At IMTEX 2023, UCAM showcased its latest range of CNC machines, rotary tables, and other solutions for manufacturing, which generated a lot of interest among visitors from various industries such as Aerospace, Automotive, Construction, Defense, Energy, and Healthcare. “They had a unique set of requirements and were looking for products and technologies that could help them improve their manufacturing process,” Vijay Zaritaklikar, National Sales Manager, UCAM Pvt Ltd.

|

Digitalization has become a crucial requirement for businesses in today's fast-paced and ever-evolving world. With the widespread adoption of digital technologies, organizations are leveraging these tools to streamline their operations, enhance efficiency, and improve their overall business outcomes. |

The company also showcased its latest range of smart machines designed to increase efficiency, reduce downtime, and optimize the entire manufacturing process. “We noticed a significant interest from visitors towards digital and smart manufacturing, which indicates that the Indian Manufacturing sector is moving towards Industry 4.0,” he says echoing similar sentiments as other exhibitors.

Anant Deshpande, Executive Director, U-Tech Associates, notes that more and more people are looking towards including Industry 4.0 in their factories. “Although there are various companies involved in developing smart systems for the Machine tool industry, somehow the awareness was not there among the actual users. IMTEX 2023 has definitely helped in closing this gap by making end users aware of the systems available. In the next two to three years, digital/smart manufacturing will be a necessity for the industry as a whole.

U-Tech mostly had visitors from the Automotive and Aerospace industries. “One more interesting observation was that Russian business visitors were more. They were very seriously looking for partnerships with Indian companies,” he points out.

IMTEX 2023 emphasis on digitalization

Digitalization has become a crucial requirement for businesses in today's fast-paced and ever-evolving world. With the widespread adoption of digital technologies, organizations are leveraging these tools to streamline their operations, enhance efficiency, and improve their overall business outcomes. As a result, we can expect to see significant progress in the manufacturing industry in the coming years. Digitalization will enable manufacturers to create more personalized products, optimize their supply chains, and reduce costs, among other benefits. Overall, digitalization is the need of the hour, and those who embrace it will be better positioned to succeed in the future.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe