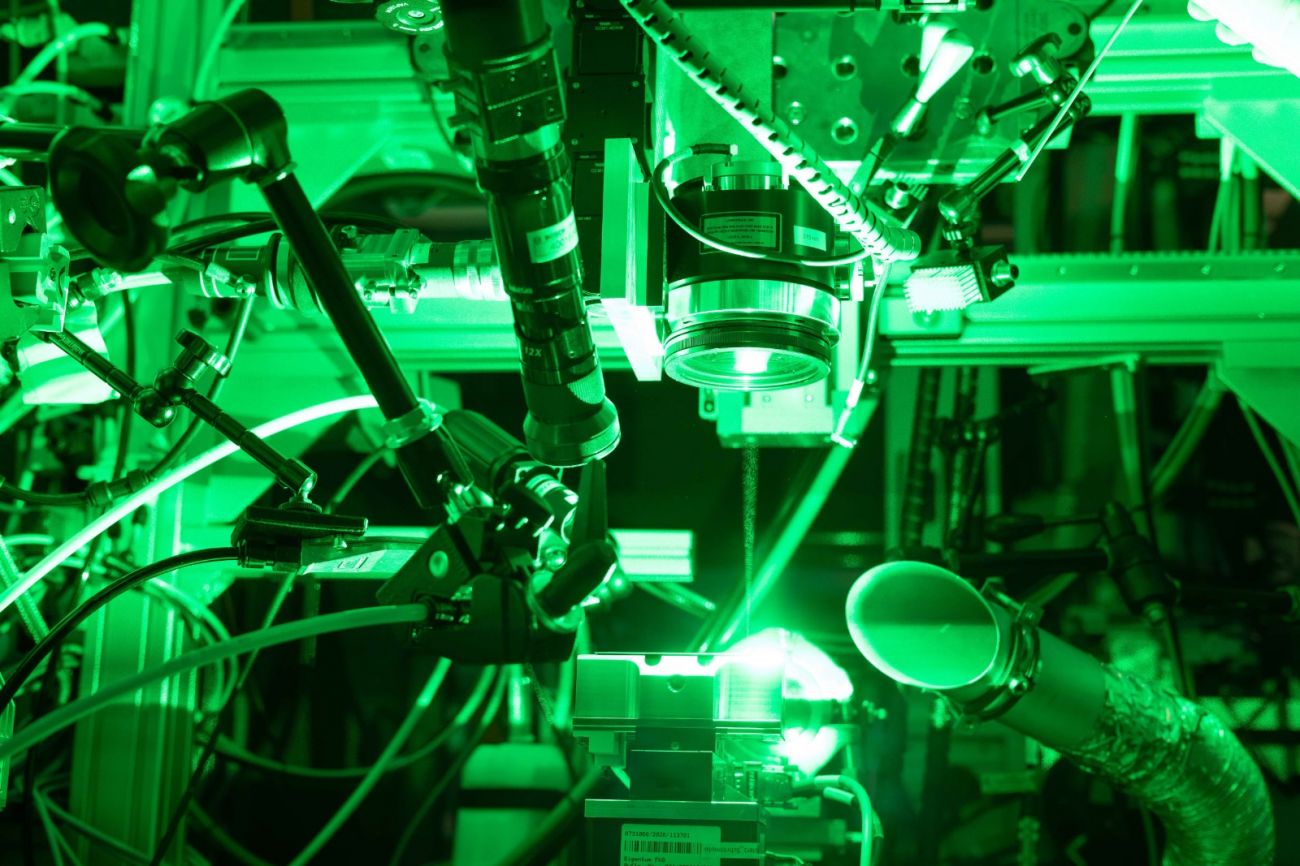

Particle Accelerator Shows Sustainable Green Wavelength Laser Welding for E-cars

Lots of raw materials can be saved in the welding of high-performance electronics. This is the result of an investigation at the German Electron Synchrotron (DESY) of the Helmholtz Association in Hamburg. High-performance electronics are in every e-car and, as a key technology, ensure the best performance of the battery and motor. The Hamburg researchers, together with the high-tech company TRUMPF and the Fraunhofer Institute for Laser Technology (ILT), have now investigated the laser welding processes that are used in the manufacture of e-cars. TRUMPF, Fraunhofer ILT, DESY, and the Helmholtz Center Hereon each contributed their highly specialized knowledge of X-rays, laser sources, and welding processes. As a result, insights that remain invisible to the eye and even to microscopes have now been achieved for the first time. The result: When a laser with a green wavelength is used, far fewer rejects are produced than with other laser welding processes. Car manufacturers save raw materials and thus contribute to more sustainable manufacturing.

Particle accelerator provides detailed insights

The project partners used brilliant X-rays of the particle accelerator at the Hereon experimental setup for their investigation to take high-speed images at several thousand to ten thousand frames per second. “We wanted to use the investigations at the particle accelerator to find out exactly what makes the difference in copper welding. A stable welding process is important because manufacturers of electric vehicles have to weld several billion connections of the highest quality,” says Marc Hummel, Scientist, Fraunhofer ILT. In the future, TRUMPF and the Fraunhofer ILT plan to expand research to other areas such as 3D printing, laser cutting, and laser drilling with ultrashort pulse lasers, and to bring other industry partners on board.

|

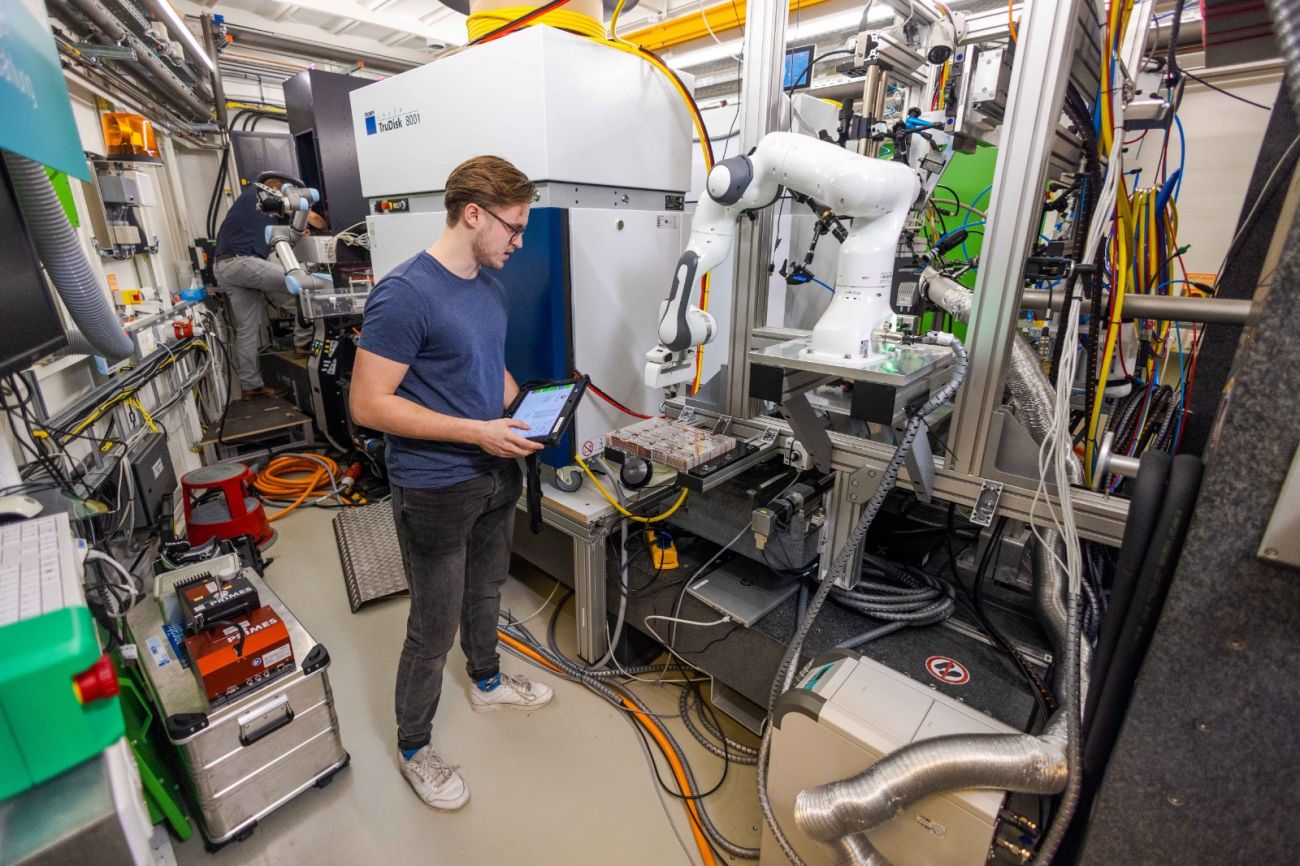

Research at the particle accelerator: TRUMPF and the Fraunhofer ILT conducted research on laser welding at a particle accelerator at the German Electron Synchrotron (DESY) in Hamburg. |

E-mobility: Fewer rejects thanks to lasers with green wavelength

Electromobility poses major challenges for laser technology. Copper is the most important material for the manufacturing of core e-mobility components. This nonferrous metal absorbs only about 5 percent of laser radiation in the near infrared range (NIR) and conducts heat very well. Both of these properties lead to considerable problems when welding. The processes are therefore under scrutiny. In addition to NIR lasers, TRUMPF also has lasers with green wavelength in its product range. “Lasers with green wavelength are the solution to this problem. In fact, copper can be welded better with these lasers,” said Mauritz Möller, Automotive Industry Manager, TRUMPF. Copper absorbs the green wavelength much better than infrared. Because the material thus reaches its melting temperature more quickly, the welding process also starts faster, and less laser power is required. “More stable processes when welding mean fewer rejects and thus greater sustainability, which is a major issue in emobility,” added Möller.

Experiments at the particle accelerator

To study welding processes in detail, experts from the Fraunhofer ILT, in collaboration with the Chair of Laser Technology LLT at RWTH Aachen University, use DESY’s PETRA III X-ray light source on the experimental setup at the Helmholtz Center Hereon. “Conventional methods actually only see the electromagnetic emissions from plasma. With DESY’s radiation, we can not only look inside the melt, but we can even make the melt dynamics visible,” explained Hummel. To do this, a team from Fraunhofer ILT and TRUMPF studied laser welding processes at DESY using two different laser systems: an NIR laser and a laser with green wavelength. “For us, this is a great opportunity to study welding processes on industrial parts. For example, how do spatters and pores form, and how does the heat from the welding process affect sensitive components such as electronic parts,” concluded Möller.

Image Source: TRUMPF SE + Co KG

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe