REMEMBERING JOHN T PARSONS

MMI pays tribute to John T Parsons, the inventor of CNC Technology who is considered by many to be the father of the second industrial revolution.

Every day hundreds of thousands of CNC machines churn out millions of products. Virtually, almost every product we use in our daily lives has been touched by CNC technology somewhere in the process.

Numerical Control marked the beginning of the second industrial revolution and the advent of an age in which the control of machines and industrial processes would pass from an imprecise craft to exact science. The impact of this invention is little understood, yet its applications range from Computer Chips to Medical, Aerospace, Machine Tools, Marine, Surface Transportation, Oil and Gas, Defence, Electronics, Clothing, Mobile phones, etc

The man behind CNC

Even though CNC has become a household name, not many people are aware of John T Parsons, the inventor of CNC Technology and considered by many to be the father of the second industrial revolution.

Computerized Numerical Control, or CNC as we all know it, came about shortly after WWII as a result of the Aircraft industry’s desire to produce more accurate and complex parts.

|

| The story of numerical control starts with John Parsons becoming aware of the use of accounting machines for solving engineering problems and employing this technique to check helicopter rotor blade airfoil patterns. |

The story of numerical control starts with John Parsons becoming aware of the use of accounting machines for solving engineering problems and employing this technique to check helicopter rotor blade airfoil patterns.

These developments were done in collaboration with his Chief Engineer and Vice President of Engineering, Frank L Stulen, whom Parsons hired when he was head of the Rotary Wing Branch of the Propeller Lab at Wright-Patterson Air Force Base, USA in April 1946.

Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades.

In the 1940s, a ‘computer’ meant a punch card-operated calculation machine. At the time John Parsons’s company Parsons Corporation had made only made one prototype of a helicopter propeller, but Parsons convinced Sikorsky Helicopter that they could produce extremely precise templates for propeller assembly and manufacturing.

He ended up inventing a punch card computer method to calculate points on a helicopter rotor blade. Parsons and Stulen generated two-axis coordinate tables of the contours for checking the airfoil patterns, utilizing early model punched card tabulating equipment. Once they were able to define the pattern numerically, Parsons then had the idea to use the same data to direct the machine and thus define the part numerically.

An ordinary milling machine was extensively modified – the table, cross-slide, head drives, and controls were removed, and three variable-speed hydraulic transmissions were installed and connected to leadscrews. Each transmission would produce, through gearing and leadscrew, a 0.0005-in. motion of the table, head, or cross-slide for each electrical pulse received from the director. A feedback system was provided to make sure the machine was doing what it was told. A synchronous motor geared to each motion generated a voltage response to movement, which was sent back to the director and compared with the original command voltage

By 1951, the system had been assembled, and application studies were begun and in a couple of years, enough data had been assembled to indicate practical possibilities that could be developed.

Patent received

MIT was also at the same time developing a similar protype that employed a Flexowriter and its eight-column paper tape, a tape reader, and a vacuum-tube electronic control system.

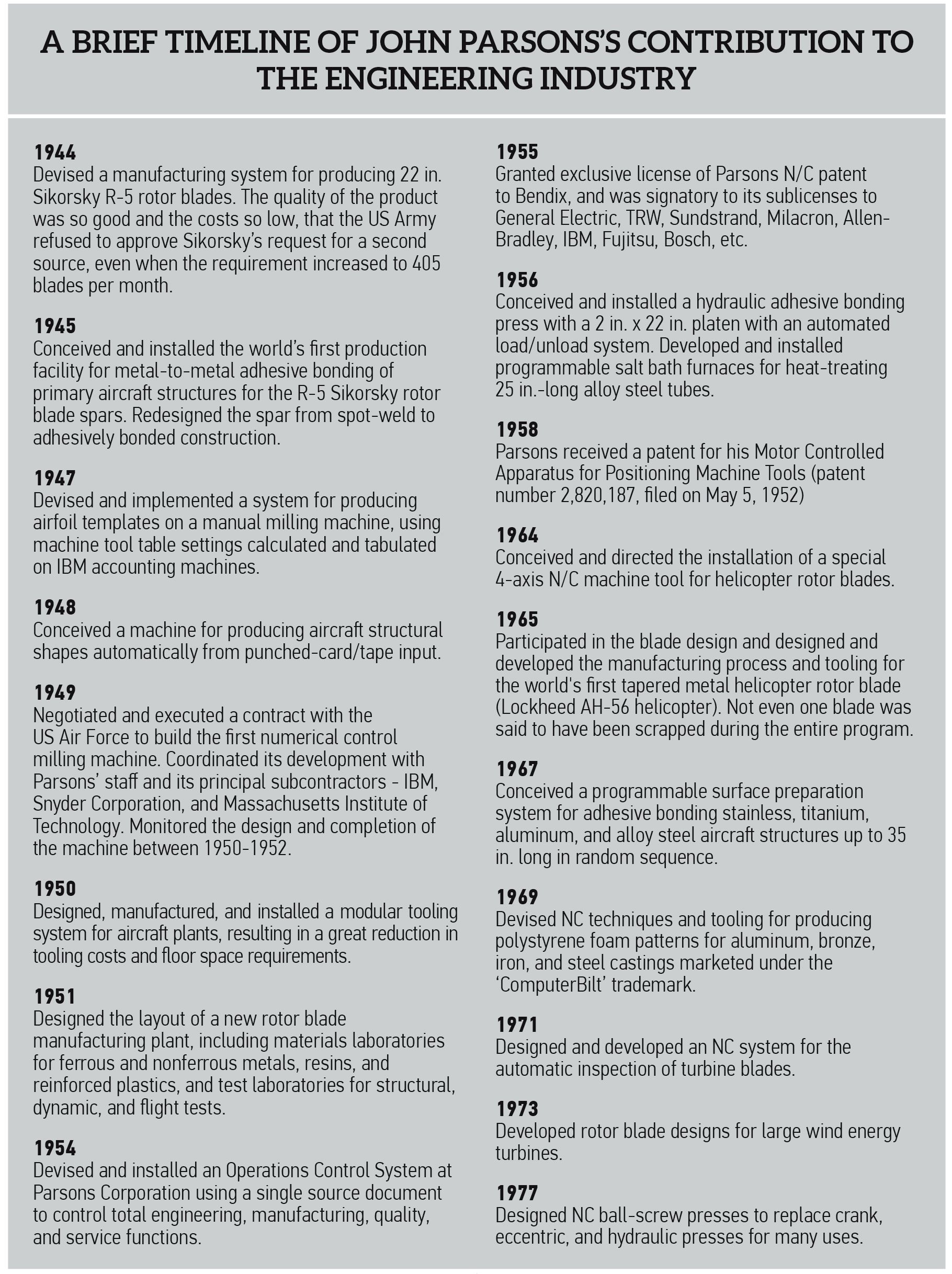

Parsons’s patent application arrived three months before MIT’s and on January 14, 1958, he received a patent for a Motor Controlled Apparatus for Positioning Machine Tool (patent number 2,820,187, filed on May 5, 1952)

Initially, the NC concept was slow to catch on as the people selling the concept were computer engineers and not machine tool engineers. By the early 1970s, however, the US Army itself popularized the use of NC computers by building and leasing them to numerous manufacturers. The CNC controller evolved in parallel with the computer, driving more and more productivity and automation into the manufacturing processes, especially machining.

John Parsons’s genius spawned many other inventions that benefitted a wide range of industries. He pioneered adhesive bonding in metal aircraft structure and then built the first all-composite airplane. He produced the gigantic fuel lines for the Saturn booster that propelled US astronauts towards the moon, and he brought computer technology to aircraft design, manufacturing, and real-time management reporting. Parsons also developed NC produced evaporative patterns to replace weldments and streamlined castings, which revolutionized the production of automobile body dies.

|

Parsons’s invention of Numerical Control has created employment for millions of people around the world and has changed the way we approach manufacturing forever. |

Winning accolades

In 1968, John Parsons became the first recipient of the Numerical Control Society’s ‘Joseph Marie Jacquard Memorial Award’. The Society of Manufacturing Engineers awarded him a plaque in 1975, naming him ‘The Father of the Second Industrial Revolution’ and in 1985, Parsons and Stulen received the National Medal of Technology from President Ronald Reagan.

Parsons, who didn’t have a college degree, was also awarded an honorary Doctor of Engineering degree from the University of Michigan in 1988. He was inducted into the National Inventors Hall Of Fame in 1993 for inventing numerical control systems, joining a long list of luminaries like Alexander Graham Bell, Thomas Edison, Henry Ford, Steve Jobs, etc.

Parsons’s invention of Numerical Control has created employment for millions of people around the world and has changed the way we approach manufacturing forever.

Tech Talks is a column by industry veteran and journalist Reji Varghese that talks about the latest advancements in Machine Tools, provides snippets from history, interesting facts, etc. about the Machine Tool industry.

|

Reji Varghese MD RV Forms & Gears fngreji@gmail.com |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe