Tebis Revolutionizes Production Machining with Digitalization & Automation at EMO 2023

Martinsried, Germany – Tebis AG is set to showcase its cutting-edge solutions for production machining, highlighting the pivotal role of digitalization and automation in enhancing efficiency and flexibility, at the EMO at Booth A28 in Hall 9, from September 18-23, 2023. A live demonstration of the process will use parts, which will also be presented on the machines at Tebis’s cooperation partners’ booths.

Trends like the skilled labor shortage, disruptions in supply chains and rising costs for materials and energy are also affecting manufacturing companies involved in machining. The industry is therefore searching for ways to improve efficiency and flexibility in order to manufacture more parts faster. The result is that more machines need to be operated by fewer employees. This solution is reinforced by increasing automation with pallet changers or handling systems. Machining centers have to be capable of unattended operation in order for employees to be able to manage these tasks. This means that the machine needs an NC program that covers all the necessary operations, from the setup of a blank and provision of the required tools to removal of the part. This NC program has to be complete and error-free.

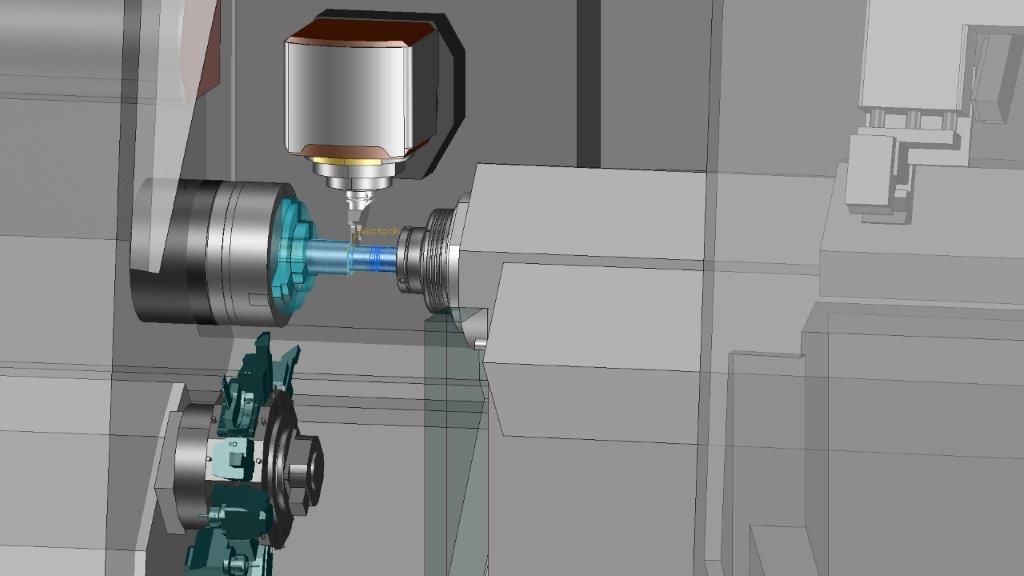

Achieving this goal requires digitalization and automation before the machine: i.e., before machining. If all the tasks are prepared in advance in the virtual world using precise digital twins, there won’t be any surprises during machining. For example, if the programmer has a precise digital model of the planned setup situation and the machine and works with digital twins of the machining tools, including precise geometric data and cutting data tested in practice, the result is an NC program that already fulfills most of the above requirements. A subsequent complete simulation in the CAD/CAM environment provides the final safety element for all traverse movements and limit switches. This is also ensured by output via a post processor that’s been certified by the CAD/CAM provider. This delivers complete NC programs with sequences for turning, milling, drilling, and even measurement integrated in the process.

Fast NC programming with automated rules in a knowledge base

Modern automated machining centers have a high part throughput and therefore require a large volume of NC programs. This means that the NC programming process needs to be automated. This is achieved by compiling the company’s manufacturing knowledge, saving it, and making it available in the form of automated rules in a knowledge base. These rules enable the process from data input, data preparation, and preparation of the setup situation to the finished NC program to be reduced to a small number of steps for the user for entire classes of parts.

Services for efficient and flexible processes

A reliable service for establishing and implementing the software, digital twins, and knowledge bases is crucial to ensuring that manufacturing employees aren’t distracted by having to create and maintain the corresponding processes.

Machining companies in production machining that have established these processes in their manufacturing with digitalization and automation are benefiting from high throughput and high adaptability. This gives them the efficiency and flexibility they need.

Image Source: Tebis AG

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe