HIGHLIGHTING MANUFACTURING PROWESS

Delhi Machine Tool Expo (DMTX) taking place from August 24-27, 2023, at Pragati

Maidan in New Delhi, will showcase an exhaustive range of state-of-the-art technologies. Here’s a sneak peek into the remarkable advancements in manufacturing that await visitors at the expo…

3D Printing Solutions

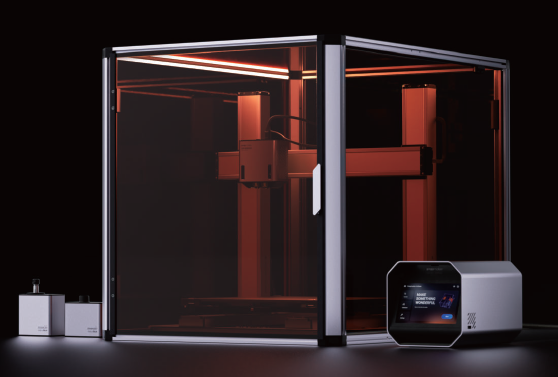

Snapmaker Artisan 3-in-1 3D Printer

|

3idea Technology is an emerging company at the forefront of cutting-edge technology solutions and is a leading provider of 3D printing solutions in India. The Snapmaker Artisan 3-in-1 3D Printer combines the functions of 3D printing, laser engraving and cutting, and CNC carving and cutting. It incorporates several notable features: Industrial-grade transmission technology: Artisan’s linear modules are embedded with steel guiderails made through CNC grinding at a micron level. This enhances precision, rigidity, and durability, resulting in a fast, accurate, and stable fabrication experience. Quick-swap platforms and tool heads allow for seamless shifting between the three functions within just one minute. The Artisan is equipped with a large 7 in. touchscreen interface for intuitive control and operation. |

|

|

3idea Technology |

Specific capabilities of each function

3D Printing:

The glass build plate offers excellent flatness and improved adhesion for the first layer. It features a glossy glass surface on one side and PEI coating on the other, facilitating filament adhesion. The Artisan has a maximum build size of 400 mm × 400 mm × 400 mm with a single nozzle, or 350 mm × 400 mm × 400 mm with a dual nozzle. Users can select from nozzle diameters of 0.2 mm, 0.6 mm, and 0.8 mm. The nozzle temperature can reach up to 300°C, while the bed temperature can reach 110°C. The Artisan supports a maximum printing speed of 180 mm/sec.

Laser Engraving & Cutting:

The laser engraving and cutting function offers a work area of 400 mm x 400 mm. It utilizes a 450 nm-460 nm semiconductor laser. The machine achieves engraving speeds of up to 6000 mm/min. It can cut materials up to a maximum depth of 8 mm. The Artisan is equipped with a powerful 10 W laser module that enables faster and deeper cutting on various materials, while delivering refined laser engraving. The laser module features beam splitters and beam shaping optics, allowing for high-quality laser work with precise details. The Artisan comes with an enclosure that reduces the laser from Class 4 to Class 1, ensuring enhanced user safety.

Laser CNC Carving & Cutting:

The CNC carving and cutting function also offers a work area of 400 mm x 400 mm. It supports a spindle speed of up to 18,000 rpm. The Artisan includes a 200 W CNC module with a shank diameter ranging from 0.5 mm to 6.35 mm. The high-rigidity linear modules and high-speed spindle empower the CNC module to carve or cut smoothly on various materials, with a dimensional accuracy of up to 0.2 mm.

CAD/CAM software

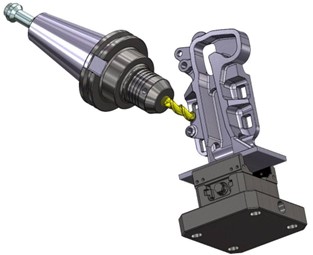

Mastercam 2024

Mastercam 2024 improves machining with powerful toolpaths, faster setups, flexible tool motion, and its most intuitive interface. Top 10 new Mastercam 2024 features,

- B-Axis Contour Turning: Tool axis vectors, usable insert area, and stock function can now be manually edited.

- Turret Mounted Angled Milling Heads: Users can now create toolpaths on angled planes using turret-mounted angled milling heads in Mill-Turn operations.

- Process Hole Improvements: The process hole toolpath applies previously defined processes to a part’s solid hole features, which consist of one or more hole-making operations’ built-in functions library.

- Holemaking Enhancements: The hole-making and multi-axis toolpath dialog boxes now have a ‘display graphical elements’ button for more personalized control on a hole-by-hole basis or across the toolpath.

- Dynamic Motion — Maximize Engagement: The Dynamic Mill, Face, and Dynamic OptiRough toolpaths now include a Maximize engagement option that generates more nominal chips, reduces small chips, and prevents stand-alone material slivers.

- Waterline Enhancements: Waterline toolpaths now recognize undercut stock, improving toolpath motion and less air cutting.

|

|

|

Mastercam India Pvt Ltd |

Horizontal Machining Centers

HX Series from Jyoti

Jyoti has developed a state-of-art HX Series of Horizontal Machining Centers to match the demand of multiple face machining operations in a single set-up with high accuracy and precision for heavy components like Gear Box Casing, Engine Head and Engine Cylinder, Valve Body and Pump Body, etc.

The machines are equipped with a feature that enables the machining of components in multiple stacking, resulting in enhanced rigidity and productivity. Wider T- Base structure provides structural stability for moving columns and helps in vibration-free cutting. The column of the machine comprises step-up base construction, resulting in better load distribution.

|

The 3-Point leveling system prevents deformation and twisting of the bed when subjected to a higher load condition. The triangular column construction supports the axis in an extreme position, ensuring high rigidity under demanding cutting parameters. The ATC of the machine has a servo-driven bi-directional magazine which takes the shortest path, resulting in the shortest overall machining time. The ATC is located outside of the machine area, which allows the operating machine and ATC simultaneously. With Geared Head as an option, one can perform large-size milling and heavy boring with high cutting parameters where high torque is required. Circular entry Auto Pallet Changer with load carrying capacity in the range of 400 to 800 kg and Rotary table with 1° indexing offers higher productivity. The machines are designed while taking care of TPM-friendly and ergonomic design concepts. The machines offer the possibility of online interfacing, providing flexibility with the choice of either hydraulic or pneumatic features. HX Series includes HX 400, HX 500, HX 510, HX 600, and HX 610 models under it. |

|

|

Jyoti CNC Automation Ltd |

Anti-Vibration Tables

Providing a Stable Surface

An anti-vibration table, also known as a vibration isolation table or vibration-free table, is a specially designed table that reduces or eliminates the transmission of vibrations from the table’s surface to its surroundings. These tables are typically used in scientific laboratories where sensitive equipment such as microscopes, balances, and precision measuring instruments need to be placed on a stable and vibration-free surface to ensure accurate results.

Series DIT-AM-W, low-frequency vibration damping with auto-leveling

Dynemech anti-vibration table DIT-AM has a natural frequency in the range of 1.5-2 Hz. along with a self-leveling feature. Available self-leveling is +0.01 mm and +0.1 mm variants with minimum setting time. Membrane air springs damp most of the incoming vibration above 3 Hz

|

.The table includes a granite insert to aid in measurement stability. The rigid, welded, sturdy table base is constructed with heavy-duty powder-coated steel with a wooden board top that can be used to keep tooling or assist in equipment working by a person. The central granite top, on which the instruments rest, is doubly isolated from traveling vibrations. The level difference on top of the granite surface due to load changes and the equipment is compensated in milliseconds. Casters are available as an option. The following applications benefit from the usage of this equipment: labs housing sensitive scientific and measuring instruments, metrology equipment, high precision weighing balances, analytical or control balances, electronic instrumentation in biological and environmental research, TGA, digital hardness testers, high-resolution microscopes, surface roughness testers, and biosafety cabinets. |

|

|

Dynemech Systems Pvt Ltd |

Rotary Tables

Enhancing Productivity

|

The NIKKEN NCT200 is a compact rotary table offering an exceptional clamping torque of 900 Nm and a 25 percent increase in rigidity, without any premium expense. The NCT200 allows one to reduce operator intervention, finish components in significantly fewer operations, and maximize machine capacity to enhance productivity and quickly see the return on investment. The CNC260PLUS is NIKKEN’s latest rotary table with a completely reimagined and updated clamping system. This new internal design takes better advantage of standard pneumatic supplies, enabling various applications to be machined without the need for an additional hydraulic power pack. This table is commonly used on a wide range of vertical machining centers to provide 4th-axis capabilities at a minimal outlay while providing optimum NIKKEN reliability, making it a highly sustainable investment. The brake system can generate a clamping torque of 1430 Nm, which is 2.4x more powerful than the original CNC260 (1430 Nm is achieved from a 5-bar air supply with 1550 Nm being possible from a typical 6-bar workshop supply). The CNC260PLUS makes a great solution to maximize the use of one’s machining center and can be mounted vertically or horizontally to suit any application. |

|

|

Indo Nihon Technologies |

Shoulder Milling Cutters

Double-Sided Insert Type Shoulder Milling Cutter

WWX series includes high-performance shoulder milling cutters that achieve excellent finish machined surfaces, feature a uniquely developed proprietary ‘X-type’ insert for strength, and are also economical. The double-sided insert with 6 corners has a large R-wiper edge to achieve excellent surface finishes even when using standard inserts.

|

The main features of the WWX series include:

|

|

|

MMC Hardmetal India Pvt Ltd |

Multistation Robotic Grinders & Polishers

For That Much-Desired Polish

This multi-station robotic automatic polisher is a compact automatic unit that combines a grinding and polishing station, automatic dosing system, ultrasonic cleaning station, and an integrated tank used in a laboratory to check the microstructure of the metals. It offers intuitive and easy operation via a PLC touchscreen and a user-friendly system.

In the case of automatic polishing, the sample is fixed in a sample holder and pressed onto the polishing medium (polishing paper, polishing cloth etc.,) with a grinding and polishing head. The polishing medium sits on the top of a working disc. A series of grinding steps follow whereby each new step makes use of an even finer polishing medium to proceed step by step towards the grade of the polished surface desired. During the whole process, a lubricating and cooling fluid ensures that the sample is cooled, and the waste material is washed away.

|

The last scratches are polished by removing a final layer. This step is the most important with a diamond suspension in poly or mono for getting mirror finish polishing to check in microscopy. Program control helps to record every process and give repeatable results at all times. Polishing is a vital step in the sample preparation process, aiming to attain a reflective flat surface while eliminating scratches and defects. This enables microscopic analysis and hardness testing for the final inspection of microstructural analysis. Chennai Metco provides a diverse range of polishing machines that cater to customer requirements, including options for manual or automatic operation, single disc or double disc configuration, and individual pressure or central pressure systems. It also provides necessary consumables to achieve fine polishing using diamond discs, abrasive papers, polishing cloths, diamond suspensions, diamond pastes, aerosols and lubricants etc. |

|

|

Chennai Metco Pvt Ltd |

Power Chucks

High Precision, Ultra-large BR Series

|

Kitagawa Power Chucks have been selected by the world’s leading machine tool OEMs for over 50 years. After many years of research and development, Kitagawa introduces its next-generation high-precision, ultra-large, through-hole BR Series Power Chucks. The gripping accuracy is 0.01 mm T.I.R. or less, providing a high level of precision. The Jaw-lift is minimized, resulting in improved performance. It is interchangeable with Kitagawa B-200 and BB200 series. When using the Tnut-Plus optional dedicated T-nuts, the repeatability of jaws during detachment and attachment is 0.01 mm T.I.R. or less. |

|

|

Kitagawa India Pvt Ltd |

Vertical Machining Centers

New DNM Series

D N Solution Korea has launched its new DNM Series of machining centers (DNM 4500, 5700, 6700). These are the enhanced versions of its global bestselling DNM II Series that are designed to machine parts with even higher productivity and accuracy.

The new DNM Series offers larger cutting space, table size, and maximum load while maintaining the same footprint as the previous DNM II Series, as well as a faster tool change time for improved productivity. The new DNM Series is equipped with direct-coupled type spindles (8000/12000 rpm, 18.5/11 kW) and a thermal error compensation system, which are essential for stable machining, as standard features. Furthermore, the lubrication of the axis travel system has been changed from oil to grease type, greatly reducing maintenance costs and improving the work environment.

Highest machining capacity of the class

The new DNM Series offers a cutting space 6 percent larger than that of previous models, with increased X and Y travel distance, for the same machine footprint. Table size has been enlarged by 14 percent to facilitate the processing of larger work pieces with more complex shapes and more space for additional rotary table, while the maximum table load has been increased by 25 percent to accept heavier workpieces. Increased spindle power and torque compared to the previous models boast maximized cutting capacity. In addition, the direct drive spindle provides improved acc/dec rates which reduce spindle start/stop time and improves the productivity of rigid tapping.

Standard direct-coupled spindle for higher productivity

The new DNM Series adopts the direct-coupled type spindle (8000 r/min, 18.5/11 kW) in place of the belt-driven type as a standard feature, greatly reducing vibration and noise from the spindle during high-speed operation. Tool change time is reduced by 14 percent compared to the previous models and idling time is further reduced with improved spindle and feed shaft acceleration and deceleration performance. Direct-coupled spindles can also reduce thermal displacement by about 40 percent, enabling more stable machining. In addition, Doosan's unique themal error control system substantially reduces the influence of heat on machining accuracy.

|

Friendliness to the environment and the operator Unlike previous models which used slideway oil, the new DNM Series employs the grease lubrication system, improving the work environment and reducing the annual maintenance cost by 55 percent. Dispensing with the inconvenience of oiling the machine every three days, users only need to grease it once every three months. In addition, since the slideway oil does not mix with the coolant, no oil skimmer is required and no unpleasant odors are generated. The new DNM Series features the Auto Recovery function, thus resolving the problem of Changer Arm stoppage during operation and enhancing the operator’s convenience. In addition, E.O.P (Easy Operation Package) function can be observed through pop-up windows, and the Multi Machine Monitor function is provided as a standard to maximize the operator’s convenience. |

|

|

Machine Tools India Ltd |

Industrial Automation & Electrical Instruments

Multispan Offers Custom-Made Solutions

Multispan is into the development and manufacturing of industrial automation instruments and electrical instruments like power analyzers. Brand Multispan has a wide presence in over 50 countries in the Asia and MENA region. The current sales team with over 25 people across India works closely with customers to deliver custom-made solutions.

|

Since 1986, Multispan is the manufacturer of:

|

|

|

Multispan Control Instruments Pvt Ltd |

Voltage Stabilizers + Transformers

Volset Brand Combo Unit

|

Sai Enterprises, a leading manufacturer in Panchkula, Haryana, is focused on quality and, hence, has earned a significant position in the industry. The above-mentioned combo unit is a space-saving solution for CNC machine users. The servo voltage stabilizer and isolation step-down transformer are mounted in a single cabinet. Its salient features include an unbalanced type, micro control circuit, copper winding, digital display of voltage, MCB at input, high/low voltage protection through contactor at output, single phasing trip, overload trip, phase reversal trip, and options for energy meter and bypass switch. Its users include Mahindra and Mahindra Ltd, Yamazaki Mazak India Pvt Ltd, Sona Comstar, Hero MotoCorp Ltd, Sigma Automotive Materials Pvt Ltd, and Uno Minda Ltd. Other products from the company include Servo Voltage Stabilizers Air and Oil Cooled, Isolation Transformers, and Single Phase Stabilizers. The company offers installations and service support across the country. |

|

|

Sai Enterprises |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe