NORD DRIVESYSTEMS Enhances Parcel Logistics with Sustainable Drive Solutions

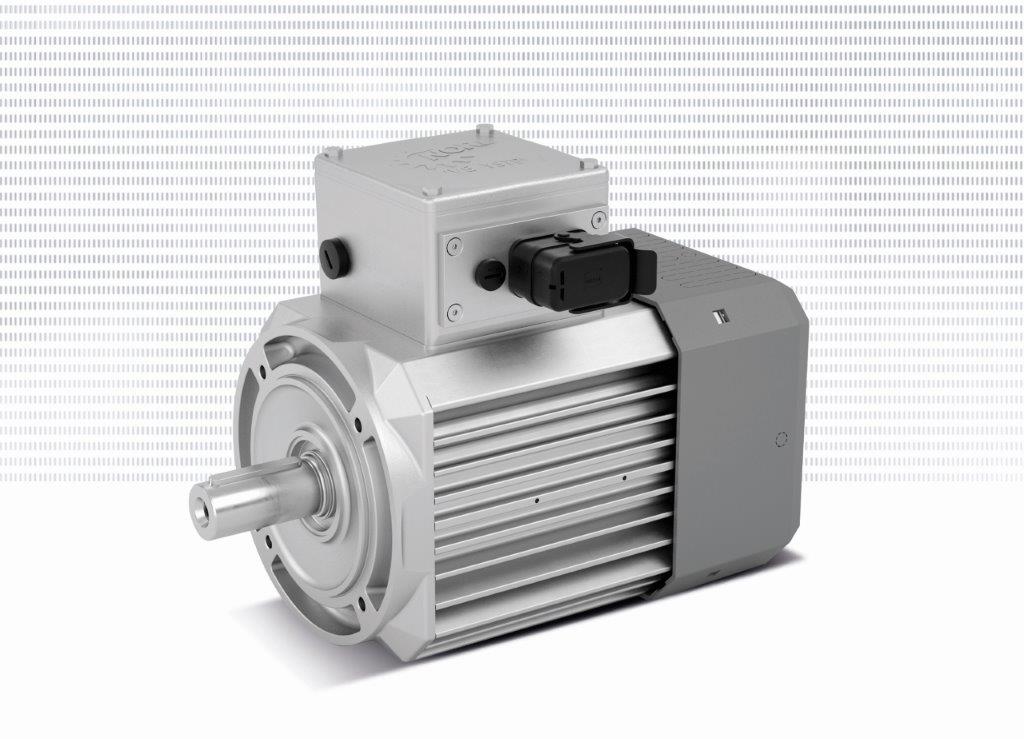

NORD DRIVESYSTEMS with its tailor-made drive solutions, supports operators of parcel distribution centres in increasing the energy efficiency of their conveyor systems and thus in reducing their CO2 emissions. The high-efficiency IE5+ synchronous motor from NORD forms the basis of many tailor-made drive concepts for intralogistics.

However, what performance does a drive system have to deliver to cope with this maximum load in the long term? This question is a source of concern to logistics providers when it comes to the construction of new plants or the modernization of existing ones. There is no easy answer to this question, as it is not only about delivering performance but also about considering further factors such as operational reliability, Total Cost of Ownership and energy efficiency. Special focus is placed on efficiency here. Energy-efficient drive technology does not only help to save costs; every reduction of energy consumption also means a reduction of CO2 emissions.

Industry experts for post & parcel

NORD’s industry experts advise customers on these questions. Together with the customer, they configure tailor-made drive solutions from the NORD modular system, which meet the requirements listed above. The high-efficiency IE5 synchronous motor forms the basis of many drive solutions and even exceeds the highest standardized efficiency class IE5. It is provided by the company as a stand-alone motor and as an integrated system solution. In the DuoDrive geared motor, the motor is integrated into a bevel gear unit and thus adds energy saving, reduced interfacing and installation space. In the LogiDrive drive system, the configuration is completed by a decentralized frequency inverter to reduce any wiring effort.

Reducing TCO, increasing system availability

With an overload capacity of up to 300 percent, the solutions from NORD allow for the reduction of drive variants in a system. For example, by using drive technology from NORD, a leading German logistics company could reduce the number of variants from 27 to 10 in one of its parcel distribution centres. Such reduction of variants minimizes administrative costs, streamlines production, logistics, storage, and service processes, and thus reduces the Total Cost of Ownership (TCO). The minimization of downtimes is also important in the field of post & parcel. For this purpose, NORD offers its Smart Check. The modular service concept keeps intralogistics systems up to date, makes maintenance and repair predictive, and increases operational reliability and system availability.

Image Source: NORD

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe