NORD Paves the Way with Innovative Mechanical Engineering Solutions

Bargteheide/Hamburg, Germany – NORD DRIVESYSTEMS will present its large range of innovative drives for mechanical engineering at FMB 2023, from November 8-10, 2023, in the exhibition center in Bad Salzuflen, Germany. In Hall 20, Stand D4, the presentation’s focus will be on the IE5+ synchronous motors and the decentralized NORDAC ON+ frequency inverters, which are ideal solutions for the rising electricity prices, the CO2 footprint, and the digital transformation that requires the use of highly efficient and powerful drives.

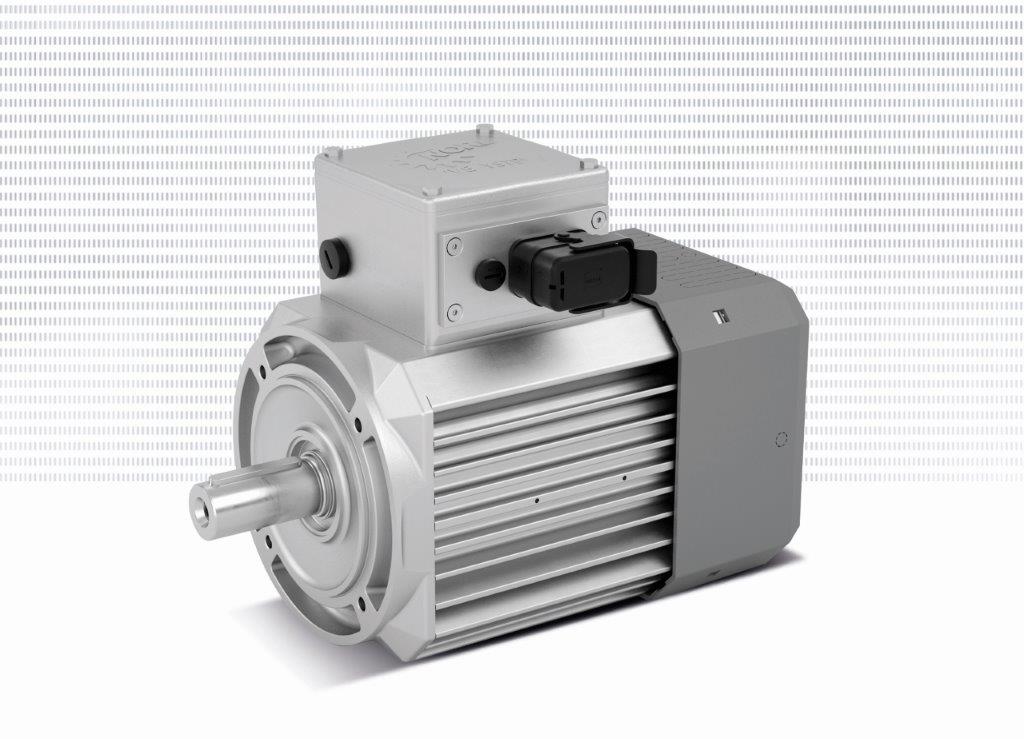

Fanless or smooth IE5+ synchronous motors

The company designed the new IE5+ motor generation with a special focus on its use in the intralogistics industry as well as the food and beverage industry. The IE5+ generation is available in both fanless and smooth versions up to a power of 4.0 kW with a continuous torque of 1.6–18.2 Nm and speeds of 0–2,100 min-1. The smooth-surface, hygienic design of the fanless variant is particularly efficient, easy to clean, corrosion-resistant, and wash-down capable. It is therefore ideal for reliable use in hygienically sensitive environments. If desired, nsd tupH surface treatment and the protection class IP69K are available. The outstanding feature of the particularly compact and energy-efficient synchronous motors is their constant high efficiency—up to 95 percent over a wide torque range. As a result, they also offer optimum energy consumption performance in partial load and speed ranges.

Frequency inverters for horizontal conveyor technology

The decentralized NORDAC ON frequency inverters provide an economical drive solution for a wide range of applications. They are perfectly tailored to the special requirements of horizontal conveyor technology—be it warehouse, intralogistics, or food & beverage. The series comprises three variants: NORDAC ON for operation with IE3 asynchronous motors, NORDAC ON+ for combination with the highly efficient IE5+ synchronous motor, and NORDAC ON PURE in wash-down design for applications in wet areas, which have to meet great demands on hygiene and cleaning. All variants are compact and powerful. They provide high functionality and—being part of the NORD modular system—can be ideally combined with the manufacturer’s geared motor portfolio. The NORDAC ON family’s excellent features are its integrated Ethernet interface, full pluggability, and very compact design. The communication protocols, for example, Profinet, EtherNet/IP, or EtherCAT, can be easily set via parameters. Firmware updates can also be implemented via Ethernet.

An economic plug-and-play solution for IIoT environments The equipment also includes a diagnostic interface, M12 connections for sensors and actuators, and an additional protocol-based encoder interface that is well protected against interference.

Highly efficient synchronous drives

The decentralized NORDAC ON+ frequency inverter has been specially optimized for combination with the IE5+ synchronous motor. As with all NORD frequency inverters, it is equipped with a powerful PLC for functions close to the drive. It can process data from connected sensors and actuators, initiate control sequences, and communicate drive and application data to the control center, networked components, or cloud storage.

Image Source: Getriebebau NORD GmbH & Co KG

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe