Carving a Niche with Precision

Guhring India, a subsidiary of the global Guhring Group, has had a notable journey in the Indian market since its inception. It has evolved significantly by leveraging its parent company’s extensive expertise in cutting tool technology and its commitment to innovation while serving diverse industries with tailored solutions that enhance productivity and precision.

Established in 1997, Guhring India initially focused on providing high-precision cutting tools and solutions to support India’s burgeoning Manufacturing sector. Gautam Ahuja, CEO & Managing Director, Guhring India, reflects on this journey, stating, “Our evolution has been marked by several key milestones aimed at enhancing local manufacturing capabilities and customer-centric solutions.”

From standard to specialized tools

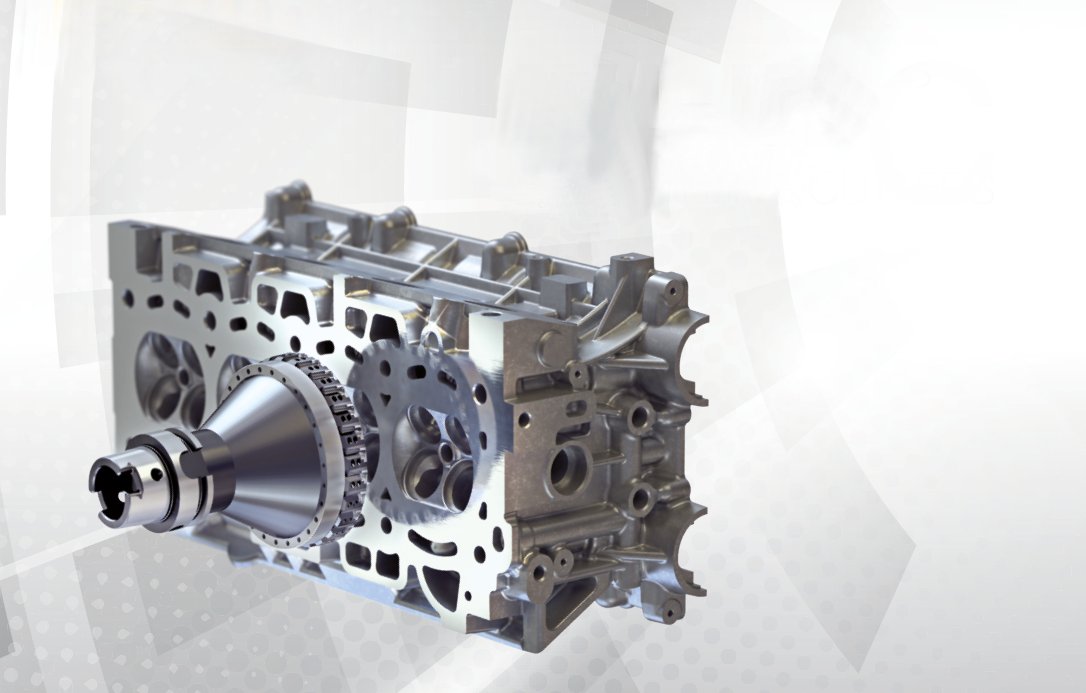

Guhring India began with a range of standard cutting tools and gradually expanded its offerings to include specialized tools tailored to meet the specific needs of various industries, such as Automotive, Aerospace, and General Engineering. Recognizing the importance of local manufacturing to better serve the Indian market, the company established a state-of-the-art manufacturing facility in Bangalore. Ahuja emphasizes that this facility not only produces Solid Carbide tools but also high-performance PCD tools according to customer requirements, ensuring flexibility and responsiveness.

Another cornerstone of Guhring India’s success has been its focus on customer support and service. “We place a strong emphasis on customer support, offering technical assistance, training programs, and application engineering services,” he shares. “This approach has helped build strong partnerships with manufacturers across India who rely on Guhring for optimizing their machining processes.” Furthermore, keeping pace with technological advancements, it has integrated Industry 4.0 principles into its operations and leveraged digital tools for tool management, predictive maintenance, and data-driven insights to enhance productivity and efficiency for its customers.

Innovation unleashed

Guhring is renowned for several product lines that have made a significant impact on productivity across various industries, including in India.

|

Twist Drills: Guhring’s twist drills are highly regarded for their precision, durability, and efficiency in metal cutting and drilling applications. They offer a wide range of twist drills tailored to different materials and machining requirements.

Thread Cutting Tools: The company manufactures thread-cutting tools such as taps and thread mills that are known for their high quality and performance. These tools are crucial for creating accurate threads in a variety of materials.

Milling Cutters: The milling cutters are designed for high-speed machining and are capable of achieving superior surface finishes and accuracy. They offer a comprehensive range of milling solutions for diverse milling operations.

PCD Tools: Guhring India has a top-notch production and inspection set-up for the manufacture / retipping of high-performance brazed-type Polycrystalline Diamond (PCD) tools in its Bangalore facility.

Micro Tools: Guhring also offers specialized solutions tailored to the precise needs of electronic component manufacturing. It provides micro drills with diameters starting from very small sizes, catering to the intricate machining requirements of electronic components. They are available in various configurations to suit different materials and machining conditions.

The company offers a range of tools for printed circuit board (PCB) manufacturing, including routers and drills specifically designed for the PCB industry.

Ensuring quality and performance

Guhring India maintains rigorous quality standards across its operations, ensuring that its products not only meet but exceed industry requirements. “The ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications from Intertek stand testimony to the commitment of Guhring India for the above purpose,” Ahuja points out.

The company ensures consistent quality and performance across its diverse product range through several key strategies and capabilities, including in-house carbide production, precision grinding machines, coating technologies, continuous improvement and innovation, stringent quality control, and a skilled workforce.

Guhring’s ability to produce carbide in-house allows for strict control over raw material quality, ensuring only high-quality carbide materials are used in its tool manufacturing processes. “This control is crucial for achieving consistent performance and durability in our products. We utilize state-of-the-art grinding machines (made by the Guhring Machine Building Department) in our manufacturing processes,” explains Ahuja. “These advanced machines enable the manufacturing of cutting tools to exact specifications, ensuring each tool meets the required geometry and cutting-edge quality for optimal performance.”

Guhring's expertise in coatings enhances tool performance characteristics such as hardness, wear resistance, and

lubricity. With its coating

facilities and technologies, Guhring can tailor coatings to specific applications and ensure consistent quality across its product range.

“By investing in research and development, Guhring India stays at the forefront of cutting tool technology, incorporating advancements that further enhance tool performance and longevity,” Ahuja adds. Additionally, the company employs highly skilled engineers, technicians, and quality assurance professionals who uphold the company’s standards of excellence.

Championing environmental responsibility

As part of its commitment to sustainability and green practices, the company undertakes several initiatives aimed at minimizing environmental impact and promoting sustainable manufacturing practices. “We focus on optimizing energy use in our manufacturing processes and investing in energy-efficient equipment and technologies to reduce energy consumption and lower carbon emissions,” shares Ahuja.

Waste reduction strategies to minimize waste generation are implemented in its operations, such as recycling materials and responsibly managing waste disposal.

Water conservation is another key focus, including rainwater harvesting, implementing water-saving technologies, recycling water where feasible, and promoting responsible water usage practices among employees.

Emphasizing the green supply chain, the company collaborates with suppliers who adhere to sustainable practices and environmental standards. This ensures that raw materials and components used in manufacturing processes are sourced responsibly, minimizing environmental impact throughout the supply chain.

Guhring India also explores the use of eco-friendly materials and designs in its products and packaging, reducing packaging waste, using recyclable materials, and designing energy-efficient products.

Employee engagement in sustainable practices is also a priority. Guhring India educates and engages employees in sustainable practices and environmental stewardship, which includes training programs on energy conservation, waste management, and the importance of sustainability in daily operations.

Furthermore, the company ensures compliance with local environmental regulations and standards. This includes monitoring emissions, managing hazardous materials responsibly, and conducting regular environmental audits to maintain environmental compliance.

Custom solutions for complex challenges

|

Guhring India distinguishes itself in the competitive cutting tools market through its customization capability and the Guhring Tool-Management Service (GTMS), offering tailored solutions that cater specifically to the unique needs of customers. The company engineers work closely with customers to understand their machining requirements, challenges, and goals and develop bespoke tooling solutions that optimize performance, improve efficiency, and reduce machining costs. “The ability to customize tools extends beyond just modifying existing designs,” he elucidates. “Guhring can develop entirely new tool geometries, coatings, and materials to suit unique machining applications or materials encountered by customers.” |

GTMS, on the other hand, is a comprehensive tool management solution that helps customers optimize their tooling inventory through analysis, planning, stocking, and replenishment based on usage patterns and production schedules. This service is particularly advantageous for large-scale manufacturing operations where efficiency and cost-effectiveness are critical. GTMS also includes ongoing technical support and training for customers’ staff, ensuring operators are knowledgeable about the tools they use, maximizing productivity, and ensuring safety in machining operations.

| Offering custom-made tools and GTMS sets Guhring India apart from competitors who may focus solely on standard product offerings. This differentiation allows the company to address niche markets and complex machining challenges that require specialized solutions. “Customers appreciate the responsiveness and personalized attention they receive, leading to long-term partnerships and repeat business,” he adds. |  |

“These capabilities strengthen Guhring’s market position as a trusted provider of high-performance cutting tools and comprehensive tooling solutions, positioning it as a preferred partner for industries demanding precision, reliability, and efficiency in machining processes.”

Global strengths,

local excellence

Since Guhring has manufacturing plants across the globe, the cutting tool requirement of the local market is met by the respective Guhring subsidiary present in the region. “In the same way, Guhring India majorly caters to the cutting tool requirement of the Indian Market. Few niche tools are exported to customers in Asia and Australia,” informs Ahuja.

Guhring India effectively balances global expertise with local manufacturing needs, particularly in the context of the ‘Make in India’ initiative, through several strategic approaches. “While we benefit from being part of a global network with 70 manufacturing plants worldwide, we have our own local manufacturing facilities in India,” he explains. “These facilities are equipped with state-of-the-art machinery and adhere to Guhring global manufacturing standards, enabling Guhring India to produce high-quality cutting tools locally.”

The company understands the specific requirements of the Indian market and industries, as it leverages its global expertise in tool design, materials, and coatings, but also adapts these technologies to suit local manufacturing practices and materials commonly used in India.

“Operating in India requires compliance with local regulations and standards. We ensure that our manufacturing processes and products adhere to all applicable Indian standards, certifications, and regulatory requirements. This local compliance enhances trust and confidence among Indian customers,” adds Ahuja.

Despite local production, Guhring India is seamlessly integrated into Guhring’s global supply chain network, allowing for efficient sourcing of raw materials, access to advanced technologies, and global best practices in manufacturing and quality control.

Additionally, the company invests in training and developing local talent to ensure that its workforce is skilled and capable of operating at international standards on manufacturing processes, quality assurance, and customer service, aligning with the company’s commitment to excellence across all operations.

Engines of sectoral growth

Several industry sectors in India are expected to create more demand for cutting tools in the near future due to various factors such as technological advancements, infrastructure development, and evolving consumer demands, as per Ahuja. He identifies some of the potential sectors that are expected to experience increased demand for cutting tools, including:

Automotive: With increasing vehicle production, advancements in electric vehicle (EV) manufacturing, and requirements for lightweight materials, there is a growing need for high-precision cutting tools for machining components.

Aerospace and Defence: India’s Aerospace and Defence industries are expanding, driven by government initiatives such as ‘Make in India’ and growth in civil aviation. This sector requires cutting-edge tools for manufacturing aircraft components, defence equipment, and space technology.

Electronics and Semiconductor: With the rise in consumer electronics, telecommunications, and semiconductor manufacturing, there is a rising demand for microtools and precision cutting solutions. These industries require tools capable of machining small, intricate components with high accuracy.

Medical Implants & Devices: The Medical industry in India is experiencing robust growth, driven by increasing healthcare investments and rising demand for advanced medical equipment. Cutting tools are essential for manufacturing surgical instruments, implants, and diagnostic devices.

Infrastructure and Construction: India’s Infrastructure sector, including projects in transportation, energy, and urban development, is expanding rapidly. Cutting tools are crucial for manufacturing construction machinery, equipment parts, and structural components.

Renewable Energy: As India transitions towards renewable energy sources such as solar and wind power, there is a growing demand for cutting tools used in manufacturing components for renewable energy systems, including turbine parts and solar panels.

|

Industrial Machinery: Various industries involved in manufacturing machinery and equipment for different sectors, including textile machinery, packaging machinery, and agricultural machinery, require cutting tools for precision machining of components. Oil & Gas: The Oil & Gas sector, particularly in exploration, extraction, and refining activities, continues to require specialized cutting tools for machining components used in drilling, pipelines, and processing equipment. |

Overall, these sectors represent significant growth opportunities for cutting tool manufacturers in India, driven by technological advancements, infrastructure investments, and increasing demand for high-precision manufacturing capabilities across various industries,” says Ahuja.

Strategic leap toward growth

| Establishing a manufacturing plant and a service center in India represents a strategic move for Guhring to solidify its footprint in the region, capitalize on growth opportunities, enhance market competitiveness, and contribute to sustainable development goals. “This outlines a pathway towards leveraging local strengths while aligning with global strategies for innovation and operational excellence,” asserts Ahuja. He further emphasizes the importance of localized production capability, stating that a local plant would enable Guhring to streamline logistics, reduce lead times, and respond more promptly to customer demands, enhancing supply chain efficiency. |  |

In terms of market penetration and growth, Ahuja notes that strengthening local manufacturing capabilities can support Guhring’s market expansion strategies in India, a rapidly growing economy with diverse industrial sectors.

Guhring India continues to set benchmarks in precision cutting tools and innovative solutions for India’s Manufacturing sector. As the company looks forward to further growth and expansion, its journey shows Guhring’s commitment to excellence and innovation in empowering Indian manufacturers with cutting-edge technologies that boost their global competitiveness.

|

Sovan Tudu Senior Sub-Editor Magic Wand Media sovan.tudu@magicwandmedia.in |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe