Creating Efficiencies

India witnesses a spurt in its demand for industrial robots pointing to the fact that domestic manufacturers are rapidly embracing automation to remain competitive. An overview of this trend that has been growing at a phenomenal pace worldwide and overhauling the ways in which we operate.

Technology is a core essential for every business today and is evolving rapidly, bringing changes to processes across sectors. The new era of robotics is set to reshape India’s entire economy.

With India's automotive, electronics and white goods sectors witnessing phenomenal growth in recent years, demand for industrial robots is also soaring. Both international and domestic auto manufacturers use robots these days for a range of activities on the shop floor including welding, paint finishing and material handling operations.

Besides ensuring accurate handling, robots also ensure consistent quality. Rising labor costs, quality considerations and hazardous tasks are making Indian manufacturers opt for industrial robots despite the relatively high capital costs.

Manufacturers are realizing the benefits of installing robots in their plants as in the long run they save costs. Robotics is slated to play a major role in strengthening India’s production capabilities, giving a massive boost to the ‘Make in India’ campaign. There is also ample evidence that robotics does not lead to a loss of jobs – a re-allocation of both jobs and tasks can have robots complement and augment human labor by performing routine or dangerous tasks. This, in turn, places a premium on higher-skilled labor in sectors that feature automated labor, while also creating new lower-skilled jobs in other sectors due to the spill-over effect.

Mounting demand world over

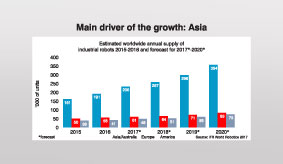

The demand for industrial robots has accelerated considerably due to the ongoing trend toward automation and the continued innovative technical improvements in industrial robots. In 2017, about 3,81,000 industrial robots were installed globally, 30 percent more than in 2016. There is considerable increase in all regions. However, Asia is the main driver with an increase of 37 percent to 2,62,000 units. Robot sales increased by 27 percent to a new peak of 2,627 units in India. It is estimated that over 3 million robots will be in operation globally by 2020. Out of which, 1.9 million will be operating in Asian factories.

Meanwhile in India

Factory automation market in India is projected to witness a CAGR of around 12 percent during 2015-2020. Growing use of robots on factory floors for increasing efficiency, reliability and accuracy of the production processes is driving the country’s factory automation market. Moreover, increasing domestic manufacturing on account of government initiatives like ‘Make in India’, is expected to stimulate growth in  automation solutions market in India through 2020. Western and Northern regions are the major markets for factory automation in India due to continuing industrial growth and presence of Special Economic Zones and various automotive hubs in these regions.

automation solutions market in India through 2020. Western and Northern regions are the major markets for factory automation in India due to continuing industrial growth and presence of Special Economic Zones and various automotive hubs in these regions.

Automotive industry, the main customer

Between 2010 and 2014, the automotive industry, the most important customer of industrial robots, had considerably increased investments in industrial robot worldwide. In 2015, robot sales increased by 4 percent to about 97,500 units establishing again a new peak for the fifth time in a row. The share of the total supply in 2015 was about 38 percent. Automotive is still the main customer with about 1,26,000 units installed in 2017, about 21 percent more than in 2016.

Challenges India faces

Automation industry players in India always have to 'justify' investments towards automation. One of the challenges is integration of various automation platforms in a manufacturing environment to avoid ‘automation islands’. Other major challenge is to convey and realize the true value of the offered automation solution to the user, avoiding commoditization in the process. One of the focus areas is to understand customers’ processes and thereby requirements and offer/execute optimum solutions to meet such requirements. This results in the implementation of optimum solutions, leading to customer satisfaction.

Today, increasing labor costs in China have caused countries like Bangladesh to grab opportunities on the basis of cost competitiveness. Hence for India the challenge is to grow without diluting its strengths and make sustainability and environmental protection an essential part of the solution. To effectively implement the global technologies, global and local players should be brought together, as global players have best of the technologies and local players know their customers best.

The way forward – Industry 4.0

The field of Industrial Automation deals with automation of manufacturing processes which helps to increase the productivity and maintain the highest quality of the end product. Different factors such as stringent quality requirement of the end products, higher production quantities, high profit margins and shorter time to market push the Industrial Automation industry to grow at a rapid pace. To meet these demands, the industry is on a lookout to implement latest technologies with smart integrated concepts. According to the latest trends, the Industrial Automation market in India is expected to grow by 15 to 20 percent based on the present capacity.

The new concept of Industry 4.0 aims to achieve the smart production with the help of its design principles namely interoperability, virtualization, decentralization, real time capability, service orientation and modularity. India, with its new ‘Make in India’ initiative, should consider these principles and implement the same in line with the advanced economies of the world to create a sustainable future of smart production factories. ‘Make in India’ should not only be about manufacturing but should be about smart and intelligent manufacturing with the possibility of customization to manufacture different products.

Robot sales increased by 27 percent to a new peak of 2,627 units in India. It is estimated that over 3 million robots will be in operation globally by 2020. Out of which, 1.9 million will be operating in Asian factories.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe