TOWARD A FUTURE-READY FACTORY

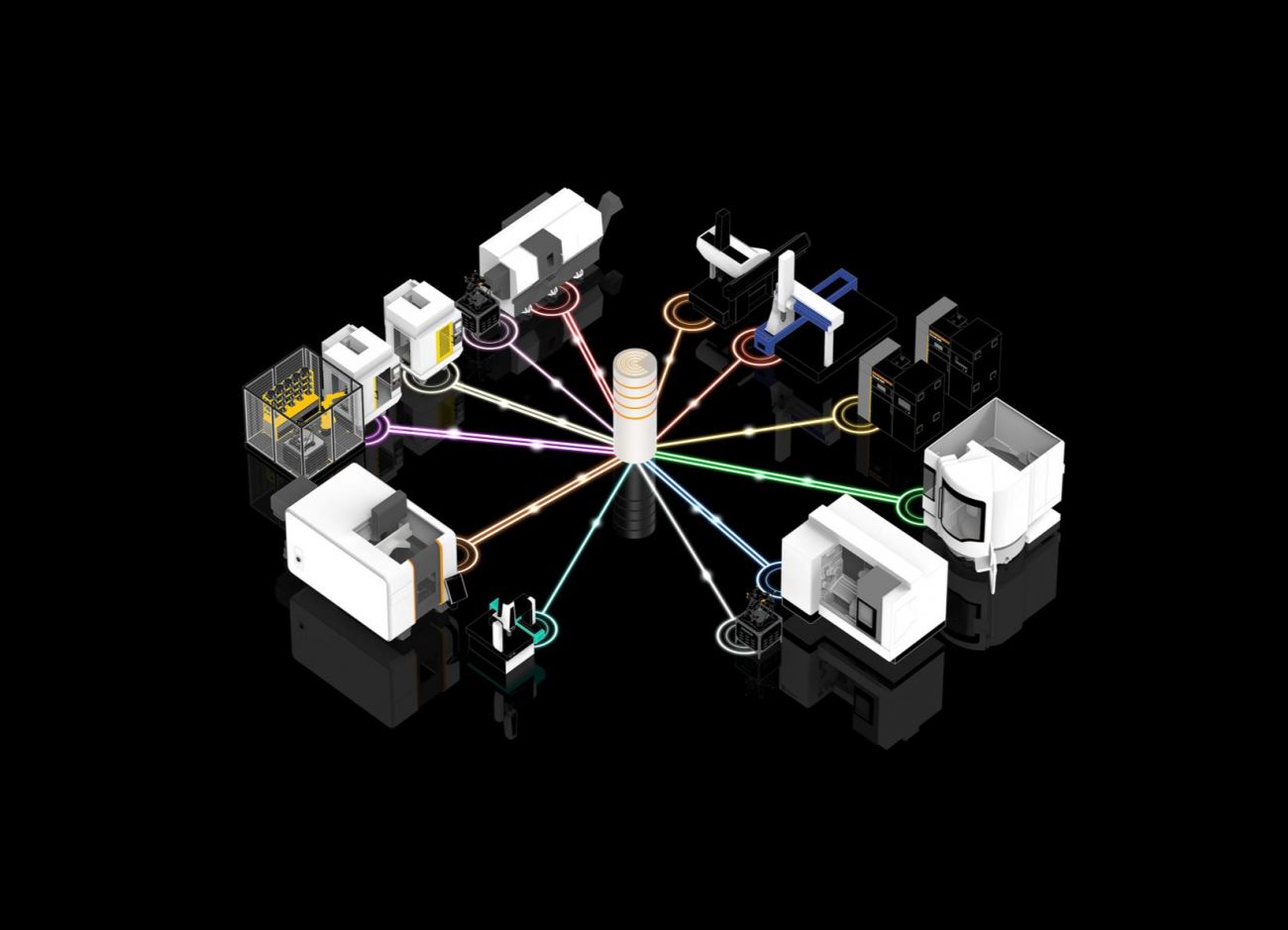

Renishaw's portfolio is playing a significant role in supporting manufacturers on their journey towards Industry 4.0. A smart manufacturing data platform for industrial process control is the solution industrial factories need. Renishaw Central is a data-driven solution designed to transform the productivity, capability, and efficiency of manufacturing operations.

Industry 4.0 brought the promise to enhance connectivity and data integration, improved productivity and efficiency,

automation and process control, optimized asset utilization and enhanced quality and reduced waste. With Industry 4.0 expansion and increasing demand for precision, India is emerging as a key player in global manufacturing, attracting significant investment.

Both global and domestic manufacturers are heavily investing in production, support teams, and new product launches. Government initiatives are transforming Manufacturing into a dynamic growth sector. With India's growing position as a manufacturing hub, the machine tools market is set for continued growth, technological advancements, and increased competition.

Industry 4.0 Myths

Renishaw Central enables users to exploit digital twin and future factory concepts through:

Connectivity: Compare efficiency, accuracy and quality across jobs, machines, and sites

Consistency: Limit variability by monitoring live quality output and enable automatic process updates

Control: Reduce process setup times on lathes with the use of Intelligent Process Control (IPC)

Confidence: Access in-depth analytic features to consolidate real-time data as reports

A World Full of Data

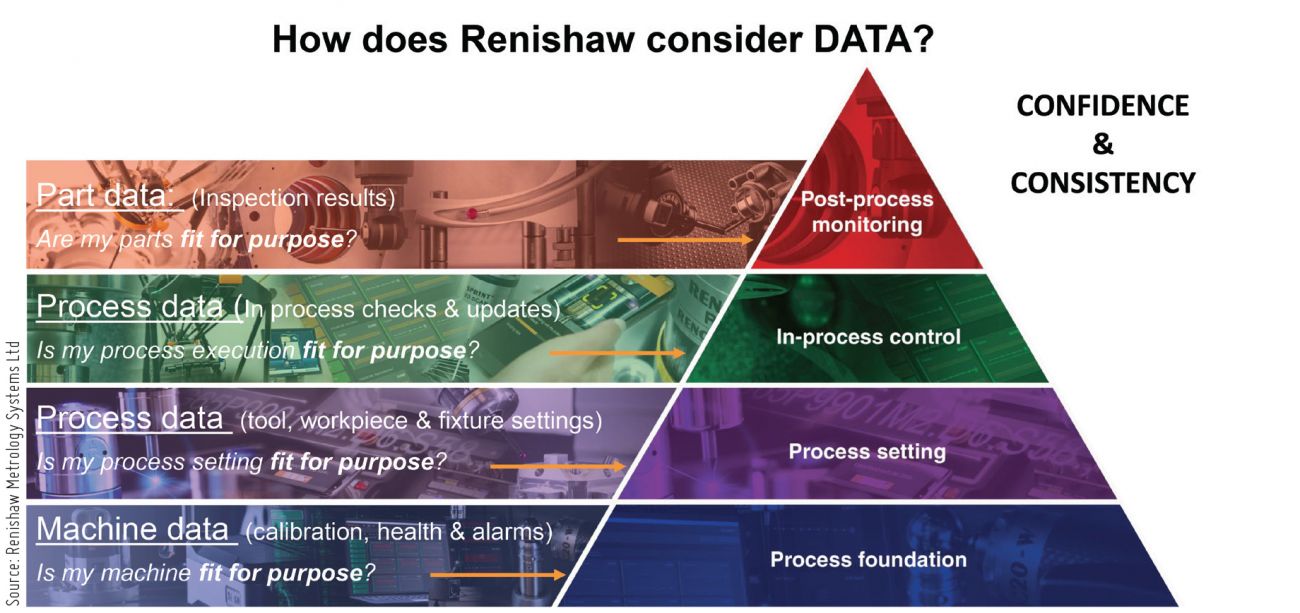

To analyze one’s manufacturing for improving the process, Renishaw has introduced a structured framework of process control, which is called Productive Process Pyramid™ in its factories. It begins with ensuring the machine tool is well-calibrated and maintained for consistent quality. This Process Foundation level ensures the machine tool's readiness, while Process Setting automates job setups with probing technology, reducing human error and labor dependence. The third level, In-Process Control, shifts measurement from the end of production to real-time monitoring during manufacturing. This allows for immediate adjustments using in-machine probing and shop-floor systems, preventing scrap or rework.

Furthermore, Post-Process Verification still involves final inspection in a standards room with CMMs, generating reports for end-users like automotive or aerospace manufacturers. Renishaw integrates all these stages with Renishaw Central, a platform that unifies metrology data and enables informed decision-making. This approach ensures every part is ‘right first time’, boosting efficiency and reducing waste.

With this, the company has helped hundreds of global customers integrate metrology and proactively apply controls using its Productive Process Pyramid™ concept. It's been Renishaw’s mission to help its customers to increase productivity, capability and efficiency of their manufacturing.

Automation, “It’s Not Just About Robots”

In the current industrial landscape, automation encompasses a wide range of technologies and processes designed to enhance efficiency, accuracy, and productivity.

The company’s perspective on automation reflects the industry's shift towards integrating diverse technologies to create more efficient, adaptable, and intelligent systems. It's about leveraging a combination of AI, IIoT, and other technologies to transform manufacturing processes and improve productivity.

Being at the forefront of automation, Renishaw integrates various technologies to improve manufacturing processes, including:

The simplest form of automation can start with using a probe. Renishaw offers a comprehensive range of probing and tool measurement solutions to enhance CNC machine tool accuracy and efficiency by automating key tasks like tool setup and part alignment.

With Renishaw Central, one can capture processes, machines, and part data, all while collecting information from multiple systems across the shop floor.

For process control, Renishaw offers shop floor gauging solutions that provide real-time data and enable immediate adjustments to manufacturing processes.

Factory automation drives operational efficiency by increasing machine uptime and overall output without the need for additional machines. By combining physical automation (like robotics) with industrial automation (like AI and IIoT) and actionable data, manufacturers can achieve closed-loop process control. This means that processes are continuously monitored and adjusted in real-time.

| With Renishaw Central, manufacturers can check the performance of devices on the shop floor, understand device utilization, and examine and validate part quality. User-friendly dashboards show live device data. |

The Key to Using Data to Improve Manufacturing

The future is happening today with Renishaw Central. Bringing the power of connectivity to the machine shop floor, the system collects accurate, actionable data on machines, parts, and processes from across the factory, and presents it centrally for insight and interrogation at the point of manufacture.

Renishaw Central collects and provides visibility of machining process data across the factory for insights into the point of manufacture. This can be used to analyze and health-check the performance of devices on the shop floor, examine device utilization and part quality, and to sign off and validate the part.

With Renishaw Central, manufacturers can check the performance of devices on the shop floor, understand device utilization, and examine and validate part quality. User-friendly dashboards show live device data. Data can be passed into industry-leading tools such as Microsoft® Power BI via APIs. Data analytics can then be used for in-process control applications and continuous improvement. This not only increases operational efficiency but also reduces the need for human intervention, building confidence in process automation.

|

CHRIS LUHMAN |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe