PRECISION IS A PASSION

Precision tooling expert HORN, in collaboration with Febametal, plays a vital role in the production of life-saving aortic valve implants at Italian medical manufacturer Corcym. With micron-level accuracy, diamond-tipped tools, and customized solutions like the Mini and Supermini systems, HORN ensures flawless machining of complex materials.

Shortness of breath, dizziness, and a feeling of pressure in the chest — if the pockets or leaflets of the aortic valve no longer open sufficiently for blood to flow, it is known as aortic valve stenosis. This heart defect can only be treated with an artificial aortic valve. The Italian company Corcym from Saluggia uses its extensive expertise to produce these implants, helping people improve their quality of life and saving lives. Tolerances in the micron range and materials that are difficult to machine are the order of the day in the production of these small marvels. To machine them productively, the company relies on tools from HORN and technical advice from Febametal.

One of the most common heart defects is aortic valve stenosis — a narrowing of the aortic valve. As a result, the flow of blood from the left ventricle into the aorta is impaired. If the narrowing is severe, symptoms such as shortness of breath, chest pressure, dizziness, and even loss of consciousness can occur. The disease is usually caused by wear-and-tear processes, such as calcification and hardening of the tissue. Aortic valve stenosis typically occurs only in old age and cannot be treated with medication. Depending on the clinical picture, an implant may be required to replace the valve. The patient’s individual condition determines whether the valve is inserted minimally invasively through the femoral artery or conventionally via an opening in the sternum.

Flaps Made from Bovine Tissue

|

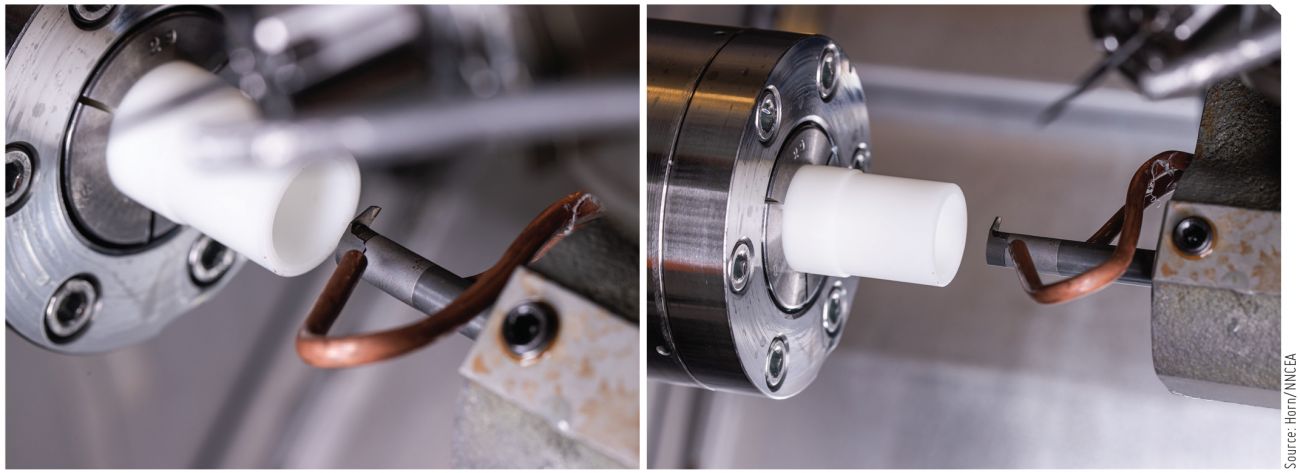

| The Mini type HORN system is used for boring. |

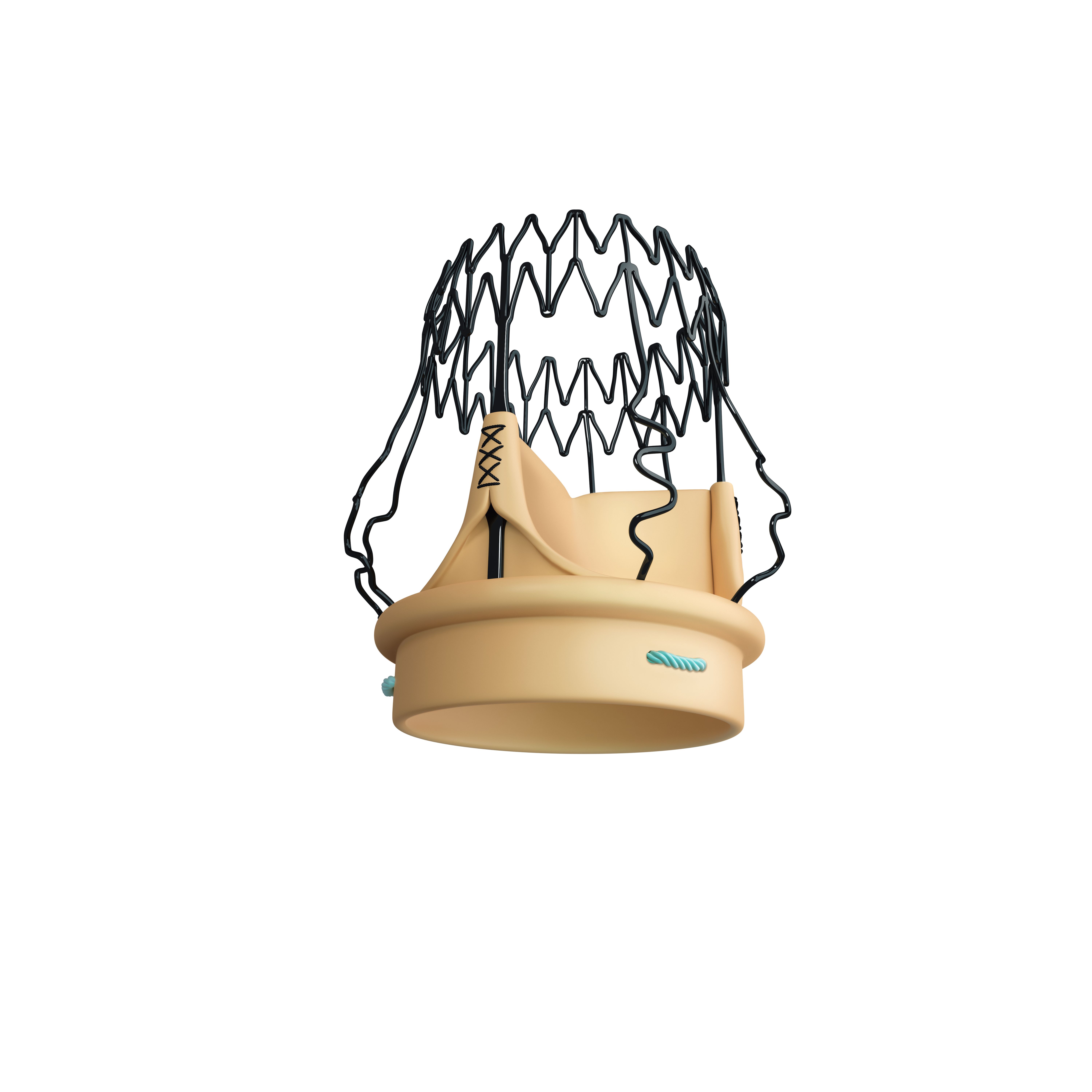

The implants differ in terms of structure and material. For minimally invasive surgery (TAVI procedure), the implant must be movable and expandable so that the surgeon can manoeuvre it through the blood vessels into the heart. Due to their short shelf life of 10 to 15 years, biological aortic valves are given to elderly people or patients who cannot undergo open-heart surgery for health reasons. The construction of a biological implant is complex. The artificial valve, made of biological material, is sewn by hand around an expandable wire mesh. At Corcym, this material is obtained from bovine tissue. The tissue, sourced from specially bred cattle, is processed so that it no longer contains any DNA or living cells, reducing the chance of rejection by the body.

The other option is the use of a mechanical aortic valve prosthesis. Mechanical valves are known for their lifelong durability, meaning a repeat operation is unlikely. The implant is inserted into an open heart while the patient is connected to a heart-lung machine during the operation. The design is simple: two movable flaps are mounted in a plastic ring that will open and close with the blood flow. A synthetic fabric is stretched around the ring. The surgeon sutures this tissue to the aorta during insertion. Even though the structure and function seem simple, the production of a mechanical aortic valve is highly complex.

Stringent Requirements

|

“The production of the mechanical components is very complex. We check every manufactured component under a microscope at 20x magnification,” explains Davide Ricchiari, Process Engineer, Corcym. The components must not have any scratches or burrs. Any imperfection, no matter how small, could lead to a stress fracture or harbor germs. Rough surfaces could also lead to calcification of the components, which would impair their function. “To ensure perfect function, all components are manufactured to tolerances of just a few microns. These tolerances are also required for implant certification. A human life depends on these components, which is why we work with the utmost care,” says Ricchiari.

The outer ring of the mechanical implant is made from a special plastic. Achieving micron-level tolerances when internally turning plastics requires a high degree of expertise. Roundness and diameter tolerance are critical. If these are not met, the two inserted valves will not seal tightly. As a result, blood could flow back into the heart due to the patient’s blood pressure. Corcym uses PCD-tipped inserts from HORN’s Mini range to bore the rings. “The material is highly abrasive. A sharp carbide cutting edge becomes dull after just a few components,” explains Andrea Panichi, Application Engineer, Febametal.

|

| A successful collaboration: Barbara Costa (Febametal) with Davide Ricchiari (Corcym) and Andrea Panichi (Febametal). |

That was precisely the reason for switching to the diamond PCD grade. Before switching to the new special material, the rings were made from a less abrasive plastic. “The production of the rings was very time-consuming. After roughing, we had to heat-treat the parts to relieve stresses in the material. Otherwise, we wouldn’t have been able to maintain the tight roundness tolerances during finishing,” says Ricchiari. With the new PCD grade, the same performance was achieved as with carbide on the older material. Heat treatment before finishing is no longer necessary with the new plastic, but the material is not easy to machine. “A sharp insert is very important,” says Panichi. Excessive cutting pressure can deform the thin-walled ring and result in ovality.

| The production of mechanical aortic valve components demands micron-level tolerances and flawless surfaces. The slightest imperfection can compromise function, introduce contamination, or lead to stress fractures—making precision machining and inspection absolutely critical. |

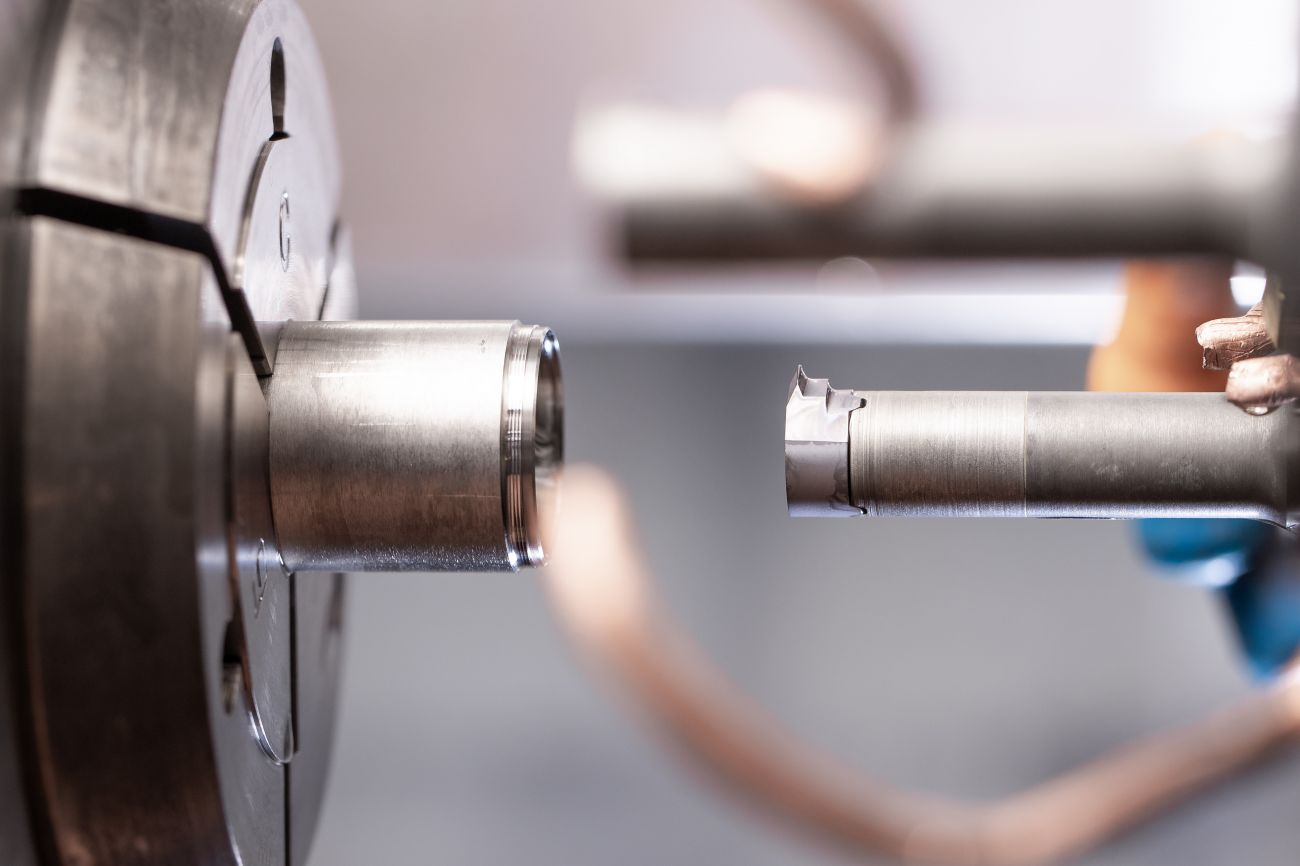

Titanium Lock Ring

|

| The mechanical aortic valve opens and closes with the patient's blood flow. |

Another important component of the mechanical aortic valve is the lock ring made from a titanium alloy. This ring tensions the tissue layer — which is sewn to the aorta — to the plastic ring. Put simply, it functions like a locking ring in mechanical engineering. If it fails, the ring with plastic flaps could come loose and travel up the aorta with the blood flow. Great care is required in manufacturing this ring. “The rings must be perfectly round on the flanks. Burrs or sharp transitions could damage the synthetic fabric when it’s tensioned. The rings are subjected to 100 percent inspection under a microscope,” explains Ricchiari.

A Mini 108 insert is also used for boring. It is precision-ground with a special profile that also allows it to be used for parting off the ring. During the production process, the machine pre-turns the rings on the outside and inside. Several rings are turned, connected by a narrow web. The rings are then parted off.

Extensive Portfolio

|

| A small miracle: the biological prosthesis can be folded up, manoeuvred through the blood vessels and unfolded again in the heart. |

The face-clamped inserts of the Mini type are one of HORN’s core products. The tool system is mainly used for turning applications. These precision tools have proven themselves in internal turning and grooving. With vibration-damped carbide tool holders, the inserts produce smooth surface finishes even with long overhangs and ensure highly reliable processes. The Mini system’s extensive portfolio includes inserts in various sizes for different internal diameters, geometries, and substrates, as well as CBN or diamond coatings.

| The face-clamped inserts of the Mini type are one of HORN’s core products. The tool system is mainly used for turning applications. These precision tools have proven themselves in internal turning and grooving. |

Corcym has relied on HORN tool solutions for over 15 years. In addition to the Mini systems, numerous Supermini types are used for boring. “We regularly test various tool systems from different manufacturers. So far, no others have delivered anywhere near as convincing a performance as the HORN products. Moreover, Febametal’s technical advice is always a great support for us,” says Ricchiari.

|

Nikhil Nayak |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe