GLOBAL MOMENTUM BUILDS AT EMO 2025 PREVIEW

In early July this year, Frankfurt pulsed with the energy of innovation as it played host to EMO Hannover 2025 Preview, an exclusive curtain-raiser to the world’s most prestigious trade fair for production technology. Organized by VDW (German Machine Tool Builders’ Association), the event, held on July 10, 2025, at the VDW headquarters, brought together a gathering of manufacturing thought leaders, pioneering exhibitors and international journalists.

Set against Frankfurt’s cosmopolitan backdrop, EMO Hannover 2025 Preview offered a compelling glimpse into the future of metalworking and advanced production systems, ahead of the main event slated for September 22–26, 2025, in Hannover. The atmosphere was electric as industry leaders unveiled cutting-edge innovations, reinforcing EMO Hannover’s position as the global epicenter of industrial advancement.

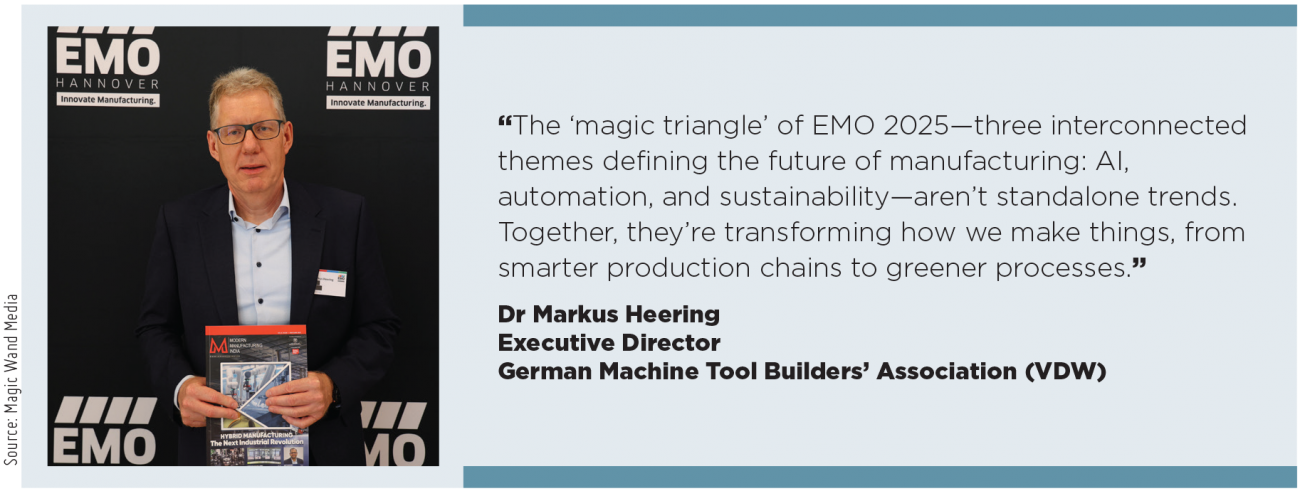

As manufacturing stands on the brink of its next transformation, all eyes are now on EMO Hannover 2025. “This year, EMO runs from September 22 to 26—five days instead of six,” shared Dr Markus Heering, Executive Director, VDW. Themed ‘Innovate Manufacturing’, the show will spotlight intelligent production, AI-driven processes, advanced automation, precision machining, and integrated digital ecosystems.

EMO Hannover Preview brought together 26 exhibitors and over 150 participants from 24 countries, including China, India, the US, South Africa, Mexico, Brazil, and across Europe. The dynamic agenda fused rapid-fire 90-second pitches, engaging Q&A sessions, insightful panel discussions, and in-depth interviews, creating a vibrant forum of ideas. A curated ETA factory tour in Darmstadt added a real-world dimension to the experience.

A Message of Confidence

Kicking off the event, Sven Krause, moderator at EMO Preview 2025, invited Dr Heering to reflect on the ‘EMO Hannover 2025 World Tour’, a six-month outreach spanning 30 countries. Dr Heering responded with marked enthusiasm, commending the remarkable preparedness and engagement of the international manufacturing community. “Nowhere else can guests encounter such a wealth of international expertise as at EMO,” he emphasized. Underscoring the event’s role as a premier platform for global industry dialogue, he remarked, “EMO is expected to send out strong signals. Exhibitors and visitors alike arrive expecting to leave in a more confident, optimistic frame of mind.”

|

Canada has been named the first-ever Alliance Country for EMO Hannover—a milestone in international collaboration that underscores the nation’s deep commitment to advanced manufacturing and its active role in shaping global industrial discourse. |

Highlighting India’s momentum, Dr Heering noted the country’s strong economic trajectory and added, “EMO is perfectly timed to meet the industry’s evolving demands. It’s where cutting-edge innovation takes center stage for those shaping the future of manufacturing.”

Tomorrow’s Manufacturing

Artificial Intelligence made its presence felt as a practical force, already embedded in real-world systems for quality assurance, predictive maintenance, and beyond. This momentum echoed powerfully during the electrifying panel discussion, ‘Perspectives on Artificial Intelligence in Manufacturing: How Will We Surprise Our Customers in the Next Five Years?’ featuring Prof Michael Zäh, Chair of Machine Tools and Manufacturing Technology at the Technical University of Munich, and Sebastian Heinz, Founder & CEO, Statworxs, Frankfurt.

According to them, European companies need to significantly increase the pace of innovation in AI in order to keep up with Asian and US providers. This is particularly true of small and medium-sized companies, which have so far been very cautious. There should be good prospects in quality assurance and predictive maintenance in particular.

Both experts emphasized AI’s transformative potential and the urgency of its adoption. “Not using AI is not an option,” asserted Prof Zäh. “Others

are already leveraging it and those who don’t will inevitably fall behind.”

Canada Makes History

|

The event blended fast-paced 90-second pitching rounds from 26 exhibitors, Q&A sessions, panel discussions, and face-to-face interviews and conversations into a vibrant showcase of ideas, as well as a factory tour. |

As the first Alliance Country for EMO Hannover, Canada’s presence is both symbolic and strategic. Canada is making a confident stride into AI-driven manufacturing, with nearly 20 pioneering companies set to showcase their innovations at a dedicated Canadian Pavilion at EMO Hannover.

| EMO Preview 2025 hosted 26 exhibitors and 150 participants from 24 countries—including China, India, the US, South Africa, Mexico, Brazil, and several European nations—alongside international media. |

“AI is part of the solution—it’s embedded in everything we do,” remarked Jayson Myers, CEO, Next Generation Manufacturing Canada (NGen). With over 180 AI-powered projects and an impressive 32X return on investment, Canada’s delegation will spotlight how AI is reinventing business models and opening new frontiers of opportunity across the industrial landscape.

Innovations every

90 seconds

Dr Heering introduced the concept of ‘Magic Triangle’ of EMO 2025: Artificial Intelligence, Automation, and Sustainability. “These are not isolated trends. Together, they are reshaping the way we manufacture—from smarter production chains to more sustainable, future-ready operations,” he pointed out.

This was also confirmed by the 26 exhibitors present at the Preview. In 90-second pitches, they described to the audience what visitors can expect to see at their EMO stand in September. Many of the pitches revolved around new machines and features, tools, automation or quick-change systems. It was all about process optimization and the use of robots with intelligent software or autonomous transport systems in the factory. Sustainability concepts were discussed, with long-lasting machines and retrofitting for a second life, as well as the question of how the carbon footprint of machines can be reduced.

| The exhibitors and speakers at the Preview made it clear that tomorrow’s machines must work longer, waste less, and consume smarter—underscoring that sustainability does not have to be just a feature, but a key performance metric. |

The exhibitors and speakers at the Preview made it clear that tomorrow’s machines must work longer, waste less, and consume smarter—underscoring that sustainability does not have to be just a feature, but a key performance metric.

Greener, Smarter Shops

3nine GmbH impressed with its Apex Series oil mist separation systems, a sustainability-leading solution capturing mist, recycling the fluid, and extending the lifespan of HEPA filters to several years. Theofil Hoffmann, Head of Sales Europe, 3nine GmbH, emphasized, “Our proven ‘disc stack technology’ captures oil mist and emulsion directly at the source, leading to significantly reduced maintenance intervals—a commitment to cleaner workspaces and lower maintenance.”

Urma AG Werkzeugfabrik is pushing for material efficiency with its modular milling and honing solutions. “The latest is the CBN milling cutter,” added Markus Probst, Manager Sales & Application, Urma. “We have CBN cutting in CBN tipping for cast iron, steel, and more.” The company will showcase the MX Boronite, MX Diamond milling cutters, and the innovative RH Reamhone at EMO Hannover in September.

Automation Takes Center Stage

The fast-paced Pitching Round revealed a wave of innovations geared toward scalable, intelligent manufacturing systems. Huron Graffenstaden SAS is transforming its expansive booth in Hall 15 into a ‘Town of Technology’—a live experience of high-speed machining, multitasking centers, and Industry 5.0-ready automation. “We’ll display around ten machines from compact turning centers to large multitasking 5-axis systems,” shared Jonathan Philipps, Director Commercial - Sales, Huron. “Four models will make their European debut.”

On the digital front, Huron is unveiling software solutions designed for Industry 4.0/5.0 integration, with features like AI-powered collision prevention, tool life optimization, and remote diagnostics—marking a bold step toward autonomous, intelligent manufacturing.

Maschinenfabrik Berthold HERMLE AG is set to showcase its cutting-edge GEN2 series of 5-axis machining centers, alongside the next-gen RS 2 GEN2 robot system and HS Flex hybrid automation.

From ANCA CNC Machines’s MicroX grinding platform, which delivers nanometer-level control for ultra-small tools, to Renishaw GmbH’s Equator–X dual-mode gauging system that enables automated part inspection and traceability, smart systems are closing the gap between machines and humans.

Joachim Jäckl, European Marketing and Communications Manager, ANCA CNC Machines, said, “We’re back at EMO in Hannover with a lot of new machines, new software, new connectivity, new automation solutions. We’re taking precision to a whole new level.” The company is extending the limits of automation, with its ‘AIMS Connect’ system that allows manufacturers to plan, manage, and guide remote operators digitally.

Similarly, speaking about the system, Rainer Lotz, President EMEA, Renishaw GmbH, stated, “We have a new mechanical construction which allows us to measure with 250 mm/sec in Absolute Mode and 500 mm/sec in Compare Mode.” He explained, “Equator–X comes with new software, MODUS™ IM is super easy to use, and can be applied by most staff you have on your shop floor.”

Precision with a Pulse

Though automation and AI could accelerate the pace of innovation, accuracy and adaptability remain the main strengths of a productive and successful production system. And there is no better place than EMO 2025 to witness such machining technologies being prepped.

At Okuma, precision meets performance—backed by Japanese technology and tradition. Posing beside an intricately machined snake model—representing Japanese culture and the year of the snake—milled out of an aluminum block, Dorian Wilger, Area Manager, Okuma Europe GmbH, pointed out, “At this year’s EMO, we are showcasing state-of-the-art technology that redefines efficiency and keeps you ahead of the competition—redefining craftsmanship.”

In a similar spirit, United Machining Solutions, the new identity born from the merger of United Grinding Group and GF Machining Solutions, is making a bold debut. Hailing it as ‘a new chapter’, Michèle Fahrni, Head of Marketing & Communication, United Machining Solutions Management AG, revealed the future plans of their premiere at EMO Hannover: “We’re unveiling eight world premieres and presenting the full force of 15 specialized brands in a single booth.”

Joining her, Michèle Zeller, Head of Marketing Communication, Fritz Studer AG, highlighted United Grinding’s brand Studer showcase within the group. “We’re bringing five machines and a loading system and are excited to reveal a brand-new Studer model at the fair,” she said.

A Preview That Delivered

As EMO Hannover turns 50 this year, Dr Heering underlined the drive behind the event, stating, “My target is for every visitor and exhibitor to leave saying, ‘We found new ideas, new business opportunities, and built new bridges for the future.’” Concluding and extending his invitation with a knowing smile, he continued, “See you in Hannover. Let’s develop and grow business—against the backdrop of the event’s ‘Innovate Manufacturing’ theme.”

|

SOUMI MITRA |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe