MODERN AEROSPACE POWERED BY A CENTURY-OLD INNOVATION

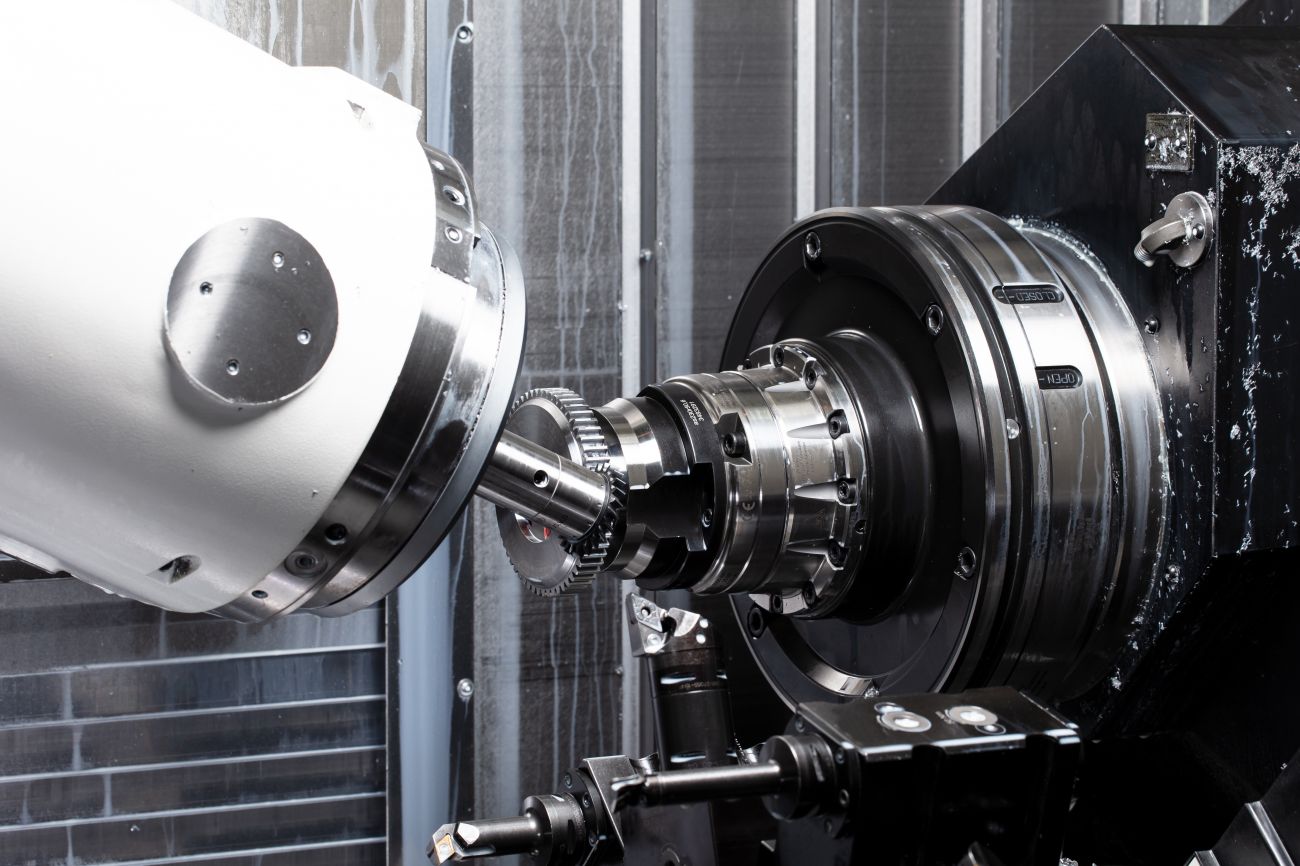

Power skiving, a gear machining process once considered too complex for large-scale use, has now become a reliable production method thanks to advances in modern machining centers and process optimization software. Collins Aerospace in Figeac, France, has adopted this technology in partnership with HORN, achieving faster cycle times, improved quality, and greater efficiency in manufacturing critical aerospace components.

Over a century ago, Wilhelm von Pittler filed a patent for a gear manufacturing process called power skiving. A revolutionary idea in 1910, it has only gained wide adoption in recent years—thanks to advanced machining centers equipped systems for controlling and synchronizing the spindle speed and with process optimization software. These technologies have transformed skiving from complex into a highly productive solution for modern manufacturing.

|

The transition to gear skiving resulted in machining time for gear teeth cut by more than 50%, reduced number of setup operations, idle time between steps eliminated, and consistent improvement in component quality. |

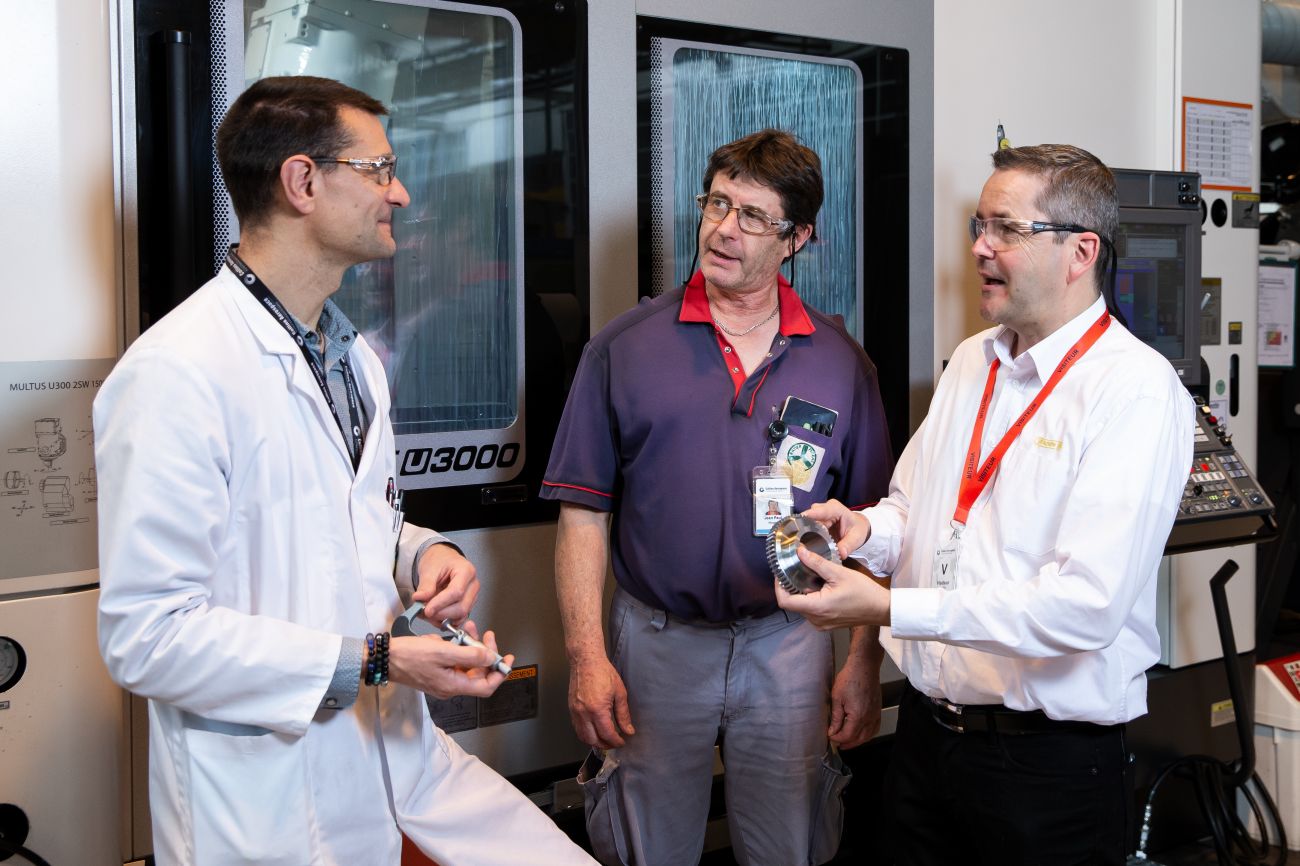

Collins Aerospace, based in Figeac, France, has been relying on this highly productive technique since 2019. Machine operator Jean-Paul Noyes, team leader Jean-Pierre Destruel, process engineer Joel Bousquet, and process developer Pascal Moulènes (the company’s specialist for gear-related matters) worked closely with tooling partner HORN to successfully implement gear skiving for a variety of aerospace components.

“Lots of companies can sell, but it’s rare to find one that can develop manufacturing strategies and actively support the implementation process,” says Moulènes. “In 2015, we saw the process being used by a machine tool manufacturer to mass-produce machine tool components.”

|

HORN’s gear cutting portfolio comprises a wide range of tools for the production of various gear geometries with module 0.25 to module 30, involving teeth for spur gears, shaft/hub connections, worm shafts, bevel gears, pinions and customized profiles. |

This got the key people at Collins interested in how they could use it themselves and influenced their decisions when selecting new machining processes. After investing in modern machining centers capable of supporting the technology, Moulènes and his team started looking for a supplier of gear skiving tools.

From Trials to Production

|

|

The launch of HORN’s system of gear skiving tools demonstrates the company’s expertise in the field of gear production. |

At EMO Hannover, the team witnessed the process live on the HORN stand. Already searching for a reliable supplier of carbide skiving tools, they partnered with HORN and began trials with technical support from engineer Emmanuel Gervais. He is the primary contact at HORN when it comes to machining critical aerospace components and he also supports the development of new tool concepts by providing valuable expertise and experience. Unsurprisingly, Gervais is based in the area of south-west France around Toulouse – the epicenter of the European Aerospace industry.

Prior to the introduction of the gear skiving process, the components were being manufactured with conventional cutting tools. “We were in the process of reorganizing the production of our families of gears,” explains Moulènes. With the help of the new technology, he was able to optimize the production processes because fewer setup operations were required and he also managed to eliminate the idle time between work steps. In addition to reducing cycle times, the technology also increased component quality.

A New Process

|

|

Gear skiving can be easily programmed on modern CNC production centers. |

“The gear skiving process was new to Collins and so we had to start by getting to know it in detail. However, we were not in a position to carry out any lengthy test runs because of the sheer volume of orders,” clarifies Moulènes.

Gervais, therefore, suggested carrying out the tests at the HORN test center in Tübingen. “The optimum machining parameters for 16NCD13 (1.6657), a material that is relatively difficult to machine, were determined in Tübingen following multiple test series. The results were reproducible across all products and the quality was consistently high,” he shares. HORN sent the test parts back to the Collins plant so the quality could be checked. The maximum permissible profile error for the gear teeth is a deviation of 0.03 mm (0.001“). The average deviation for the HORN test series was significantly lower than this. “HORN was able to supply the gear skiving tools with a concentricity correction system. Naturally, our primary aim was to achieve the appropriate level of part quality, but a long tool life was also very important to us,” adds Bousquet.

Tangible Benefits

The transition to gear skiving was seamless. “The initial tests proved immediately successful. We could directly apply the cutting data determined in Tübingen with almost no changes,” recalls Gervais. As a result: The machining time for the gear teeth alone was cut by more than half. The gear skiving process is subdivided into 14 rough machining, 2 pre-finishing and 2 finishing operations with a grinding allowance of 0.1 mm (0.004").

The hardening distortion associated with the subsequent heat treatment is not factored into the cutting profile of the tool. After hardening, the component then has to be ground. “We are currently using the same tool to manufacture five different components with the same module. So far, we have produced more than 300 parts in total. And the end of the tool life is not yet in sight,” shares Moulènes.

Productive Tool System

|

|

A partnership spanning 30 years: Pascal Moulènes with Jean Paul Noyes (both from Collins) and Emmanuel Gervais from HORN France. |

The HORN tool range includes highly productive gear skiving tools for manufacturing internal gears, splines and other internal profiles, as well as external gears with interfering edges. In these applications, the key advantages offered by gear skiving are: significantly shorter process times compared to broaching, the ability to use the technique on optimized turn-mill centers, turning and gear cutting in one clamping, and the absence of reliefs at the tooth end. Gear skiving tools are designed for gear cutting

in medium to large batches. Each tool is individually adapted to the application and to the material being machined, with the various tool interfaces based on the number of teeth and the module.

HORN’s gear cutting portfolio comprises a wide range of tools for the production of various gear geometries with module 0.25 to module 30. Whether this involves teeth for spur gears, shaft/hub connections, worm shafts, bevel gears, pinions or customized profiles, all these tooth profiles can be manufactured cost-effectively with HORN tool solutions. Gear skiving technology only came into use when machining centers started supporting the use of this complex technology by offering systems for controlling and synchronizing the spindle speed, as well as process optimization software.

A Global Company

With more than 70,000 employees based at 300 locations across the globe, Collins Aerospace is one of the biggest suppliers to the Aerospace industry. Its customer base includes all of the major international corporations in this sector. The Collins plant in Figeac is one of the world’s leading manufacturers of propeller systems for civil and military aircraft, cockpit and cabin equipment, and horizontal tail actuators. At its plant in the south of France, it also manufactures the propellers for the Airbus A400M.

Collins Aerospace and HORN have been partners for 30 years. “It all began when we started using the Mini and Supermini systems to machine Inconel,“ recalls Pascal Janot, who is in charge of tool procurement. Today, the team at Collins also uses HORN solutions for milling in addition to the Mini and Supermini systems. “Our company relies on HORN for the majority of parts where we need to cut grooves. But HORN does not just offer excellent tools. Thanks to its high-quality support and services, the company is our preferred partner,” says Moulènes.

|

HORN in India Precision Tooling Solutions for the Aerospace and Precision Machining Industries from Paul Horn GmbH are available in India via NN Combined Engineering Agencies Pvt Ltd (NNCEA). NNCEA provides complete manufacturing solutions including logistics and supply chain management solutions for a wide variety manufacturing industries in the Indian market. |

|

Nikhil Nayak |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe