JYOTI CNC AND HURON UNVEIL NEXT-GEN MACHINING

Jyoti CNC Automation Ltd, India’s largest CNC machine tool manufacturer, together with its French subsidiary Huron Graffenstaden, will present a powerful line-up of advanced machining solutions at EMO Hannover. From ultra-fast drill-tap centers to multi-axis turn-mill platforms and large-format 5-axis machining centers, the companies will highlight innovations that blend speed, precision, and automation to meet the most demanding manufacturing challenges across a spectrum of industries.

Turn-Mill Centers

|

|

Jyoti CNC Automation Ltd |

Jyoti CNC’s ATM 200 for Complex Parts

The ATM 200, part of the Vertical Line Series, is a high-performance turn-mill center designed for mass production with a fully integrated automated job feeding system. Its unique architecture features an inverted vertical electro spindle head that moves in all axes, while the front of the machine base remains open for flexible tooling layouts and automation modules. This design ensures excellent chip evacuation, easy integration of gantry or robotic loading, and versatile process customization. Equipped with a high-speed electro spindle and a live tool turret, the machine performs turning, milling, drilling, and tapping operations in a single setup, significantly reducing cycle times and manual handling.

Automation is at the core of the ATM 200, with features such as auto job feeding, multi-function stations for customized machining, and pick-up stations that enable continuous, unattended operation. These capabilities minimize operator fatigue, ensure consistent part quality, and allow lights-out production. The Y-axis on the headstock provides high rigidity and accuracy during off-center operations, making the ATM 200 particularly suited for complex parts like differential cases and other automotive or precision components that demand multiple machining processes and specialized tooling such as goose-neck cutters.

Turn-Mill Centers

|

| Jyoti CNC Automation Ltd Hall & Stand: 15/C-36 |

Jyoti CNC’s MTX 300 for Unmanned Machining

Introducing the incredible MTX Series from Jyoti that seamlessly integrates advanced 5-axis milling and 4-axis turn-mill capabilities, perfect for the intricate world of single-piece component manufacturing. With its outstanding precision, remarkable versatility, and top-notch efficiency, the MTX Series is a go-to solution for industries that demand peak performance and unwavering reliability.

It boasts a main electro-spindle featuring a C-axis and a secondary electro-spindle equipped with a Z3-axis for turning. It also includes a milling spindle with X1/Y/Z1 along with a B-axis, complemented by a live tool turret (X2/Z2-axis). Additionally, it is outfitted with a high-capacity Automatic Tool Changer (ATC) to keep one’s production running smoothly. Engineered for high-precision, unmanned machining, the MTX Series is a game-changer in industries such as Aerospace, Automotive, Mechanical, Power, and Oil & Gas. It delivers exceptional tolerance and reliability even in the most challenging applications.

Turn-Mill Centers

|

| Jyoti CNC Automation Ltd Hall & Stand: 15/C-36 |

AX-200 MY for High-Precision Industries

The AX-200MY from Jyoti CNC Automation Ltd is a next-generation multi-axis turn-mill center with a unique Y-axis design that enables complete machining of complex components in a single setup. Equipped with roller-type linear guideways and high-resolution glass scales, it delivers excellent rigidity, vibration damping, and positioning accuracy. A 12-station servo-driven live tool turret integrates turning, milling, drilling, and tapping operations in both radial and axial orientations, while the high-speed electro spindle ensures stable cutting performance on challenging materials.

Each turret movement is powered by high-torque servo motors, making the machine capable of PCD drilling, eccentric milling, and intricate OD/ID profiling without additional setups. The digital tailstock provides stable support for long components, and the combination of X, Z, C, and Y axes allows complex contouring and multi-tasking. These features make the AX-200MY particularly suited for high-precision industries such as Aerospace, Medical, and Surgical Manufacturing, where accuracy, reduced cycle time, and flexible machining are critical.

Vertical Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

High-Precision VX 8 MP-Pro from Huron

The VX 8 MP-Pro from Huron Graffenstaden is a high-precision vertical machining center designed for complex and high-volume machining applications. Built on a rigid, thermally stable structure with high-precision linear guideways, it ensures exceptional accuracy, excellent surface finish, and dynamic performance even under demanding cutting conditions. A high-speed electro spindle with advanced cooling and vibration control enables efficient machining of diverse materials, while direct-drive rotary axes support simultaneous 5-axis contouring and complex geometry machining in a single setup.

The hallmark of the MP-Pro configuration is its integrated multi-pallet system, which enables continuous machining by allowing one pallet to be loaded or unloaded while another is in operation. This capability drastically reduces idle time, enhances productivity, and facilitates seamless batch production without frequent interruptions. Combined with a fast automatic tool changer and intelligent CNC control, the VX 8 MP-Pro delivers superior throughput and flexibility, making it particularly suited for Aerospace, Die & Mold, Automotive, and Precision Engineering applications where multi-sided machining and reduced cycle time are critical.

Drill-Tap Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

Tachyon 5 FT from Huron for Ultra-Fast Operations

The Tachyon 5 FT is a high-speed drill-tap machining center from Jyoti’s Tachyon series, designed specifically for ultra-fast and precise operations. This FT variant features a fixed-table design, ensuring exceptional rigidity and stability while the moving column architecture delivers dynamic, high-acceleration movements. Equipped with a high-speed electro spindle, rapid axis acceleration, and a fast automatic tool changer, the machine achieves minimal non-cutting time and superior productivity. Its design focuses on reducing cycle time through near-instantaneous tool changes and optimized ergonomics, making it ideal for high-volume drilling, tapping, and light milling applications.

With five-axis machining capability integrated into a fixed-table platform, the Tachyon 5 FT can complete complex components in a single setup with high accuracy and repeatability. Precision linear guideways, thermally stable construction, and an advanced CNC control system ensure consistent machining performance over long runs. This model is particularly suited for industries such as Electronics, Automotive, Aerospace, and Precision Engineering, where high spindle uptime, speed, and tight tolerances are critical.

Drill-Tap Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

High-Speed Tachyon 4FT from Huron

Inspired by the theoretical particle that travels faster than light, Tachyon 4FT is Jyoti’s latest high-speed drill-tap center designed to meet the relentless pace of modern manufacturing. With cutting-edge engineering and a compact footprint, it delivers exceptional cycle times with near-zero loading and unloading delays—ideal for the Electronics, Telecommunications, and Automotive sectors. Built on a rigid moving column architecture, the machine achieves rapid traverses of up to 70 m/min and acceleration up to 15 m/s², supporting continuous, high-precision production environments. Its fixed table configuration offers a generous working envelope, while minimizing floor space—an advantage where space is a premium in mass manufacturing setups.

The advanced rotary tilting table features absolute encoders on both A and C axes, paired with a torque motor-driven C-axis. This ensures vibration-free, dynamic 5-axis performance with angular accuracy of 0.001°, empowering complex part machining with unmatched stability. Equipped with a servo-driven automatic tool changer, the Tachyon achieves chip-to-chip tool change times of just 1.6 seconds, thanks to its short arm design and motorized de-clamping mechanism. The in-house manufactured spindle, with an HSK 40A taper, offers speeds up to 24,000 RPM and a rapid 0.8-second ramp-up/down, making it ideal for fast tapping and drilling cycles.

Operational efficiency is further enhanced by a rear chip evacuation system and a positively sloped machining area, which ensure consistent chip flow and reduced operator intervention. For uncompromising accuracy, the machine is equipped with Volumetric Compensation Technology. This system corrects 18 geometric deviations and 3 squareness errors, ensuring sub-micron precision—a must for Aerospace, EMS, Medical, and other critical component industries.

At its core, SINUMERIK ONE, Siemens' digital-native CNC controller, powers the Tachyon 4FT, enabling high-end multi-axis machining. Performance is validated through ISO 10791-7 standard tests, reinforcing its capability in precision-critical applications. In every sense, the Tachyon 4FT is built not just for speed, but for speed with precision—exactly what the future of manufacturing demands.

Vertical Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

Huron’s VX 12 NVU for Large, Complex Components

The VX 12 NVU is a next-generation Vertical Machining Center engineered to meet the demanding requirements of modern machining with superior rigidity, precision, and productivity. Built on a robust cast iron structure, it offers exceptional vibration damping and thermal stability, ensuring consistent accuracy even during high-speed or heavy-duty operations.

With a generous X-axis travel of up to 1,200 mm, Y-axis travel up to 600 mm and Z-axis travel up to 610 mm, combined with rapid traverse rates of 24 m/min in all axis and a high-performance spindle, makes VX 12 NVU ideal for machining large, complex components in Aerospace, Defence, Energy, and Precision Engineering sectors. Its tool changer supports fast and reliable automatic tool swaps, significantly reducing cycle times.

With high-speed spindle options and dynamic axis movement, it delivers optimal cutting performance across a wide range of materials. The spacious work envelope makes the machine ideal for medium to large part machining in Automotive, Aerospace, and General Engineering applications. Equipped with the latest CNC controls, it ensures user-friendly operation and real-time diagnostics. Intelligent chip management and coolant systems enhance uptime and maintain process efficiency. Built for reliability, the VX 12 NVU reflects Huron’s legacy of innovation in high-precision machining. From roughing to fine finishing, the VX 12 NVU stands as a powerhouse VMC that empowers manufacturers with unmatched speed, precision, and reliability.

Horizontal Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

HP 4000 from Huron

Huron has introduced the high-performance HP Series, the cutting-edge evolution of horizontal machining centers, crafted with the foundational elements of rigidity, accuracy, and high dynamics. This extraordinary series is designed for peak performance, with the potential to boost productivity and deliver exceptional reliability, guaranteeing top-notch machining outcomes. Equipped with state-of-the-art technology and precision engineering, the HP Series sets an innovative standard for efficiency, paving the way for the future of precision manufacturing.

Built on a robust, heavy-duty bed made from high-quality graded cast iron and other resilient materials, the series features a unique Step Up Structure that enhances load distribution. Its wide T-base structure ensures outstanding stability, enabling vibration-free cutting for larger job envelopes along the X-axis, even in extreme positions without any overhanging effects—ensuring superior cutting capabilities.

Packed with intelligent features, the HP Series includes a servo-driven digital door for the ATC that synchronizes with tool length, significantly reducing chip-to-chip change time while preventing unwanted coolant or chip entry. With Jyoti electro spindles featuring HSK 100 and BBT 50 tapers, the series delivers impressive power, torque, and RPM, offering increased productivity and remarkable versatility to tackle a wide variety of machining tasks with exceptional precision.

5-Axis Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

Huron’s GU 5 for Intricate Machining Operations

The GU Series machines represent the forefront of moving gantry 5-axis technology. In today’s competitive environment, machinists require 5-axis machining centers that deliver enhanced dynamics, along with exceptional accuracy and reliability. Huron Graffenstaden’s solutions are ideally positioned to meet these critical industry demands. Offering an optimal balance of cutting-edge technology and strong return on investment, the GU Series is designed to perform intricate machining operations with precision, efficiency, and adaptability, making it a valuable asset in modern manufacturing.

With a moving gantry architecture, swivelling rotary table, and thermal stability ensured by cooling circuits surrounding the linear motion bodies and ball screw nut bracket, the series is engineered for peak performance. Its electro spindle, developed for high-efficiency machining, delivers a high chip removal rate and features an integrated cooling system that ensures smooth operation and extends service life.

The GU Series offers exceptional stability and high dynamics, enabling reliable performance and superior machining capabilities across a wide range of applications. These advanced machines serve diverse industries, including Aerospace, Automotive, Healthcare, and other sectors where precision machining is essential.

5-Axis Machining Centers

|

| Huron Graffenstaden Hall & Stand: 15/D-35 |

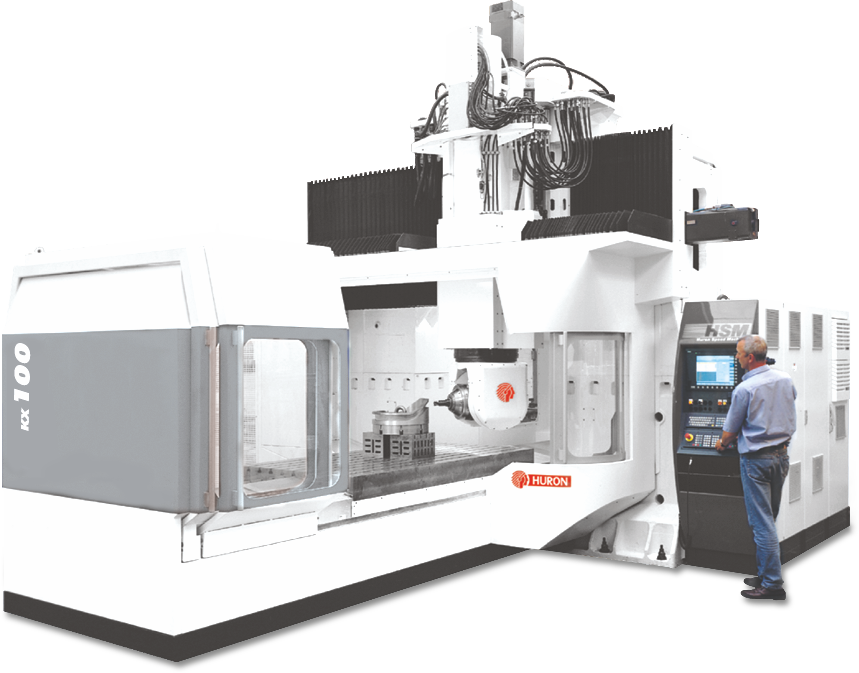

Huron’s KX 100 for High-Value, Complex Components

Direct measurement on linear and rotary axes ensures exceptional volumetric precision, while the modular design allows customization through different variants and equipment configurations. These features combine to deliver superior surface finish, reduced setup times, and long mechanical life for manufacturers handling high-value, complex components.

The KX 100 from Huron’s KX Large Series is a high-precision, large-capacity five-axis/five-side machining center engineered for the continuous production of complex parts. Its fixed-portal architecture ensures maximum structural rigidity and thermal stability, delivering high accuracy and repeatability even when machining tough materials. With an expansive work envelope capable of accommodating volumes up to 4,080 × 2,180 × 1,550 mm and a load capacity of 20 tonne, the KX 100 is ideally suited for large-scale components in general mechanical engineering, precision 3D shapes, and parts for the Aeronautical and Energy sectors.

Designed to maximize productivity, the KX 100 features a palletizing function for uninterrupted machining, wide column clearance for full utilization of the work volume, and high-performance spindles capable of both heavy-duty roughing and high-speed finishing. Direct measurement on linear and rotary axes ensures exceptional volumetric precision, while the modular design allows customisation through multiple variants and equipment configurations. These capabilities combine to deliver superior surface finishes, reduced setup times, and long mechanical life—making the KX 100 a powerful solution for manufacturers handling high-value, complex components.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe