INDIAN INNOVATION ON THE GLOBAL STAGE

Ace Designers Ltd, amace solutions Pvt Ltd, and Micromatic Grinding Technologies (MGT) Pvt Ltd from the AceMicromatic Group will present a range of advanced machining, additive manufacturing, and grinding solutions at EMO Hannover. Their showcase reflects India’s engineering expertise and commitment to delivering precision, productivity, and innovation to a global audience. Here’s a preview of the innovations that will take the spotlight, promising to capture the attention they truly deserve. Together these companies aim to further fortify India’s position in the global manufacturing ecosystem, offering customized solutions to empower their customers stay relevant in the rapidly shifting, highly-competitive industrial landscape.

CNC Turning Machines

|

|

Ace Designers Ltd |

J Series from Ace Designers

The J Series machines are precision, cost-effective CNC turning machines, ideal for job shops and ancillary units. Unlike retrofit CNC machines, the J Series is a fully-fledged CNC solution, designed and built to leverage advanced CNC features such as high rapid rates, optimized cutting parameters, and constant surface speed.

Key machine elements—including ball screws, bearings, CNC systems, and drives—are sourced from the best available globally. Assembly is carried out by a dedicated team of skilled craftsmen, working under expert technical guidance.

These precision CNC turning centers come with C-axis capability to handle a wide variety of machining needs—milling, drilling, and tapping—in a single setup, significantly enhancing productivity and versatility.

Features

- Rigid cast iron bed with step-up design for superior rigidity and extended service life

- Thermally stabilized high-speed spindle (4,500 rpm)

- 8 in. high-speed chuck with Ø63 mm bar capacity

- BMT-45 servo turret with milling capability; index time: 0.15 sec

- Machining capacity: Max turning diameter 350 mm; max turning length 460 mm

- Suitable for automation lines

Applications

The machine is suitable for a wide range of applications, including:

- Tool room components

- Automobile components

- General engineering parts

Machining Centers

|

|

Ace Designers Ltd |

540G-30 – Graphite Series Machining Center

The 540G-30 is one of the highest-selling machines in the Graphite Series (G-Series). It features a BBT-30 spindle with a high speed of 20,000 rpm, making it ideal for machining graphite materials. The machine is designed with the utmost care, using special ball screws, LM guideways, and telescopic covers to ensure that the dust generated during graphite machining does not affect the accessories or compromise machine performance.

The G-Series can be configured for both wet and dry graphite cutting applications. These machines are widely used in the production of electrodes, rotors, battery cells, furnace parts, valves, and components for nuclear reactors, among other applications.

Key Features

The 540G-30 comes equipped with a toughened glass front door for operator safety and visibility. It uses a BBT spindle taper, capable of running at 10,000 rpm for specific applications, and incorporates a spindle air curtain to prevent dust entry. For wet machining, a curtain-type coolant system is provided, along with a two-stage filtration system to ensure clean coolant flow.

A twin-arm automatic tool changer (ATC) with a magazine isolation door allows fast tool changes while protecting tools from contamination. All G-Series machines use a direct drive spindle for maximum precision. The machine is coated with a special high-gloss finish paint for durability and easy maintenance.

To further protect internal components, the machine incorporates a special double-protection telescopic cover and specially designed LM guideways and ball screws to withstand graphite powder exposure. For graphite applications, it is equipped with a dedicated coolant tank featuring a multistage filtration system. Lubrication for ball screws and LM guideways is provided through an oil lubrication system, which can be customized based on the component application.

Applications

Depending on the application, users can choose between a grease or oil lubrication system. By integrating special rotary and tilting tables, the 540G-30 can also perform 4th and 5th axis operations. It is suitable for machining graphite, ceramic, silicon carbide, carbon fiber, glass fiber, aluminum ceramic, and composite materials.

CNC Turning Centers

|

|

Ace Designers Ltd |

LT-2 Series From Ace Designers

The LT-2 Series machines are engineered for a perfect balance of power, rigidity, and productivity. These precision CNC turning centers feature a sub-spindle along with C- and Y-axes capabilities, enabling a wide range of machining operations—milling, drilling, tapping, and front/back-end turning—in a single setup. This significantly boosts machine capability and operational efficiency.

A Power-Up series motor is offered for increased torque at lower spindle RPMs. The C-axis provides bi-directional motion that can be interpolated with X and/or Z motion. Rotating cutters are mounted on the tool turret and operate in the same two axes as the turning tools.

The Y-axis serves as a third axis, allowing rotary cutters to machine across the spindle centerline. This is achieved through an additional set of ways, which move the live tool across the spindle face. This design enables production shops to quickly realize the benefits of integrating milling, drilling, and turning operations in one setup.

The machine supports full contouring movements of the workpiece, allowing profiling cuts to be made using simultaneous X-Y-Z axes motion along with the C-axis.

Applications

The LT-2 Series can handle a wide range of machining tasks, including: milling, drilling, tapping, boring, reaming, and contour milling. It is ideal for manufacturing tool room components, aerospace components, and automobile components. Once set up at the start of production, the machine runs according to the programmed instructions until the process is complete.

Machining Centers

|

|

Ace Designers Ltd |

1060V Machining Center from Ace Designers

The 1060V is a rigid and efficient machining center, designed with an ergonomically optimized structure that offers an excellent rigidity-to-weight ratio. This machine is ideally suited for machining die and mold components. Equipped with high-precision LM guideways and ball screws, it ensures outstanding accuracy and productivity.

It offers high cutting capability, a rigid structure, increased feed rates, and efficient chip removal for smooth operations.

The 1060V features a spindle speed of up to 15,000 rpm and a fast automatic tool changer (ATC) with 24 or 30 tool capacity. The spindle taper is available in BT-40 or BT-50 configurations. Rapid traverse rates are 32 m/min on the X and Y axes and 24 m/min on the Z axis. Depending on the configuration, spindle power is rated at either 11/7.5 kW or 18.5/11 kW.

Additional features include front chip disposal for easy maintenance, coolant through the spindle for improved machining efficiency, compatibility with 4th and 5th axis rotary tables, and a DM kit for extended functionality.

This machine is suitable for a variety of applications, including die and mold manufacturing, aerospace components, pattern machining, and general engineering components.

Metal 3D Printers

|

|

amace solutions Pvt Ltd |

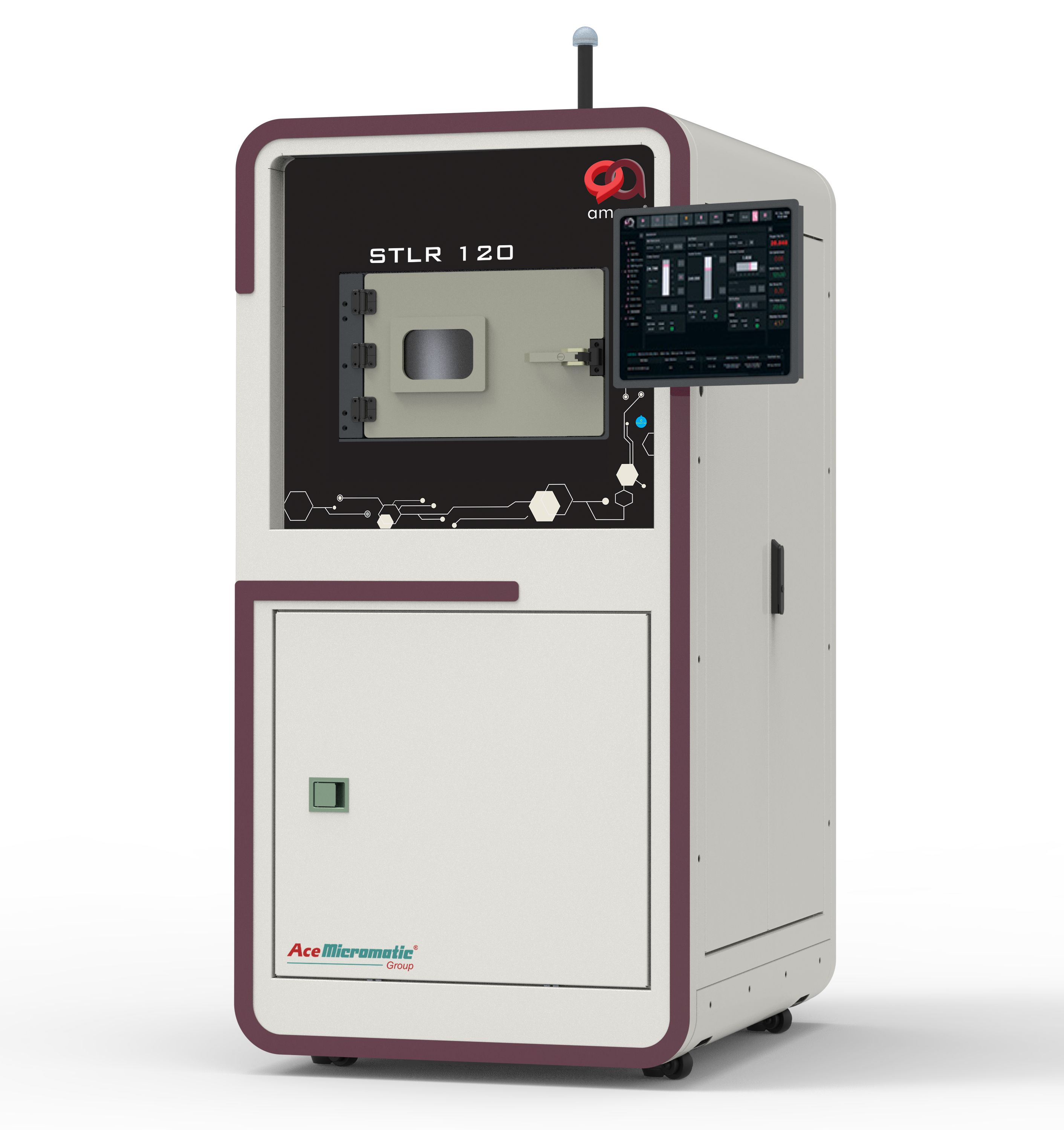

Compact Metal 3D Printer STLR 120 from amace solutions

The STLR 120 is a compact and efficient metal 3D printer designed for R&D, academic use, and small parts production. It features Laser Powder Bed Fusion (LPBF) technology and operates on a single-phase power supply, ensuring low power consumption and a minimal footprint.

Equipped with a powerful 400 W laser and a fine laser spot for exceptional resolution, the STLR 120 is ideal for producing high-quality parts such as medical implants, electronic components, and prototypes. Its capability to process a wide range of materials makes it a versatile and cost-effective solution for exploring additive manufacturing.

The printer is particularly well-suited for skill development and material research in educational and research institutions.

Grinding Machines

|

|

Micromatic Grinding Technologies Pvt Ltd |

ECO 200 – Compact Universal Cylindrical Grinding Machine

The ECO 200 from Micromatic Grinding Technologies Pvt Ltd is a compact, conventional cylindrical grinding machine designed for high-precision grinding of small components. Capable of performing both internal and external grinding in its universal model, it is ideally suited for producing small-sized, high-precision components for tool rooms and small-batch production.

This machine features a universal configuration for internal and external grinding operations. It delivers high accuracy, achieving less than 1 µm roundness on diameter as standard, with an option to achieve less than 0.5 µm roundness.

The heavy-duty cast iron bed provides exceptional rigidity and stability, while hand-scraped guideways with Turcite ensure smooth and consistent performance. The wheel head is equipped with hydrodynamic spindle bearings for enhanced reliability. The table can swivel up to 30° to facilitate taper grinding.

An automatic grinding cycle is controlled through an integrated PLC. The wheel head spindle motor, rated at 3.7 kW, provides high stock removal capability. The MK 3 tailstock offers ±0.03 mm micro taper adjustment for precision alignment.

The ECO 200 is also available in a CE-marked version.

This machine is a smart choice for high-precision, multi-purpose grinding in a compact footprint.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe