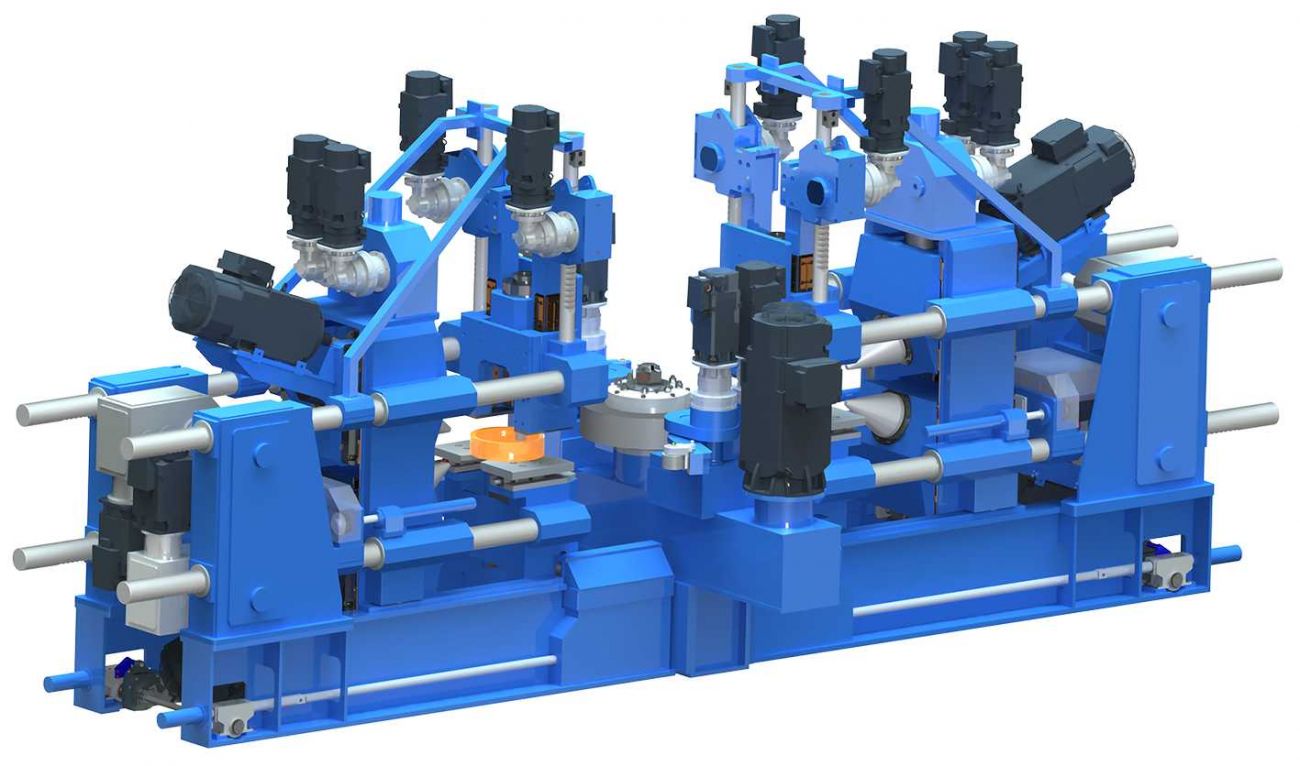

ECAI’s Double-Station Omega Ring Rolling Mill

Over the years, two kinds of high-productivity ring mills have been developed: double-station radial–axial hydraulic ring mills and multi-mandrel closed-tool ring mills. Although both are efficient, they operate on different rolling technologies.

Based on its experience with multi-mandrel and radial-axial ring mills, ECAI has designed a new machine featuring advantages of both these machine types.

The Omega® Ring Mill is designed for both radial–axial rolling and closed-tool rolling. Compact in size, it can be installed on a simple, space-efficient foundation.

It can be supplied with either one or two stations. In the two-station configuration, productivity is significantly higher, as one station can be used for unloading and loading while the other is actively rolling. The Omega® Ring Mill can also be integrated into a fully automated production line to meet high-productivity requirements.

As for the other machines in the company’s range, the radial and axial stands and the centering arms are moved by electromechanical drives, eliminating all maintenance and environmental problems associated with hydraulics.

The Omega® ring mills undergo both cold and hot testing at the company’s workshop prior to delivery. This ensures shorter installation and commissioning times at the customer’s facility, enabling a quick and smooth start to production.

ECAI

www.ecai.fr

Hall & Stall: 5/C-104

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe