Redefining Sheet Metal Folding Efficiency

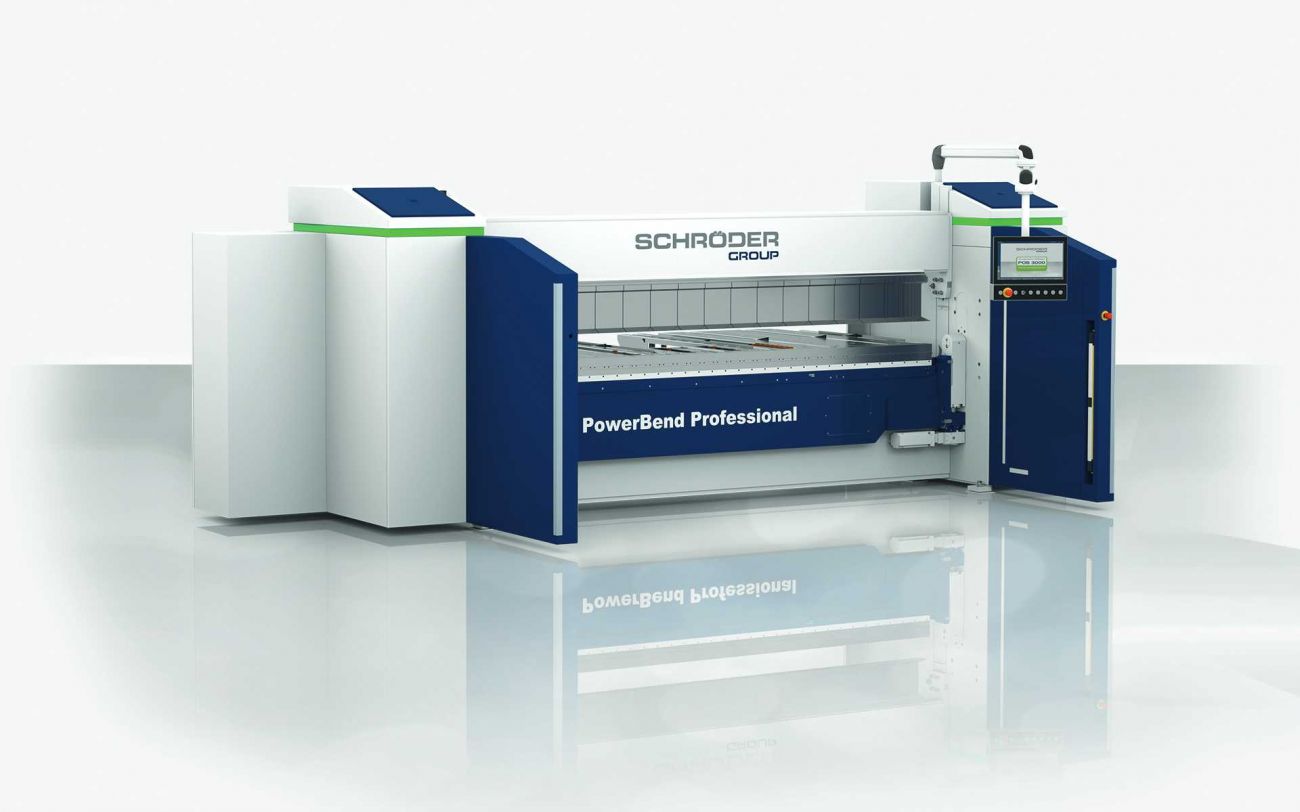

The key differentiator of the Schröder PowerBend Professional is its superior material handling efficiency, which directly enhances productivity and operator safety. Unlike conventional press brakes that require frequent flipping, aligning, and manual repositioning of sheets, the PowerBend Professional uses up-and-down folding technology, allowing all bends to be completed from a single position. This eliminates sheet flipping—a major cause of time loss, errors, and operator fatigue.

The machine’s suction gauge system, pneumatic pop-up fingers, and friction-free support tables ensure smooth, accurate, and effortless sheet movement throughout the bending sequence. Large panels, long parts, and delicate sheets can be positioned easily and safely, without strain on the operator.

In addition, the rotating clamping beam allows tool changes without lifting or repositioning the sheet, further reducing handling steps. Overall, the Schröder PowerBend Professional minimizes manual intervention, reduces handling-related defects, and significantly accelerates production—making it a safer, more efficient alternative to conventional bending systems.

RadCAM Technologies Pvt Ltd

www.Radcamtechnologies.com

Hall & Stall: 4/B-105

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe