Towards Lasting Partnerships

The Blaser coolant Blasocut 4000 Strong has a sump life of over 20 years now! It all began in 1998 when Tata Motors in Pune was looking for a high-quality metalworking fluid. Blaser Swisslube India reflects on the success story so far and is sure of it lasting for the next 20 years.

Tata is a market leader and pioneer in making commercial vehicles like trucks for ages. In 1998, the company decided to enter the passenger car market with its Indica car. For its car production, the plant in Pune was investing in high-performance technology for aluminum machining. Thus, it was on a lookout for competent partners. Its main requirement was a high-performance material removal and a reliable and robust coolant system.

After thorough research, Tata decided to get into partnership with Blaser Swisslube. This defined the beginning of its subsidiary Blaser Swisslube India in 2001. At the initial stage of the project, Hans Niederhaueser (now Retd. Sales Manager) from Blaser Swisslube Switzerland came to India to personally fill Tata’s central system. “I still remember how it all started. I flew to India in May 1998 to fill the central system with 80,000 l of our Blasocut 4000 Strong. I am very happy to see that the emulsion is still stable and running smoothly for 20 years now. By avoiding a huge quantity of coolant disposal for the last 20 years, the contribution to the greener planet is priceless,” says Hans.

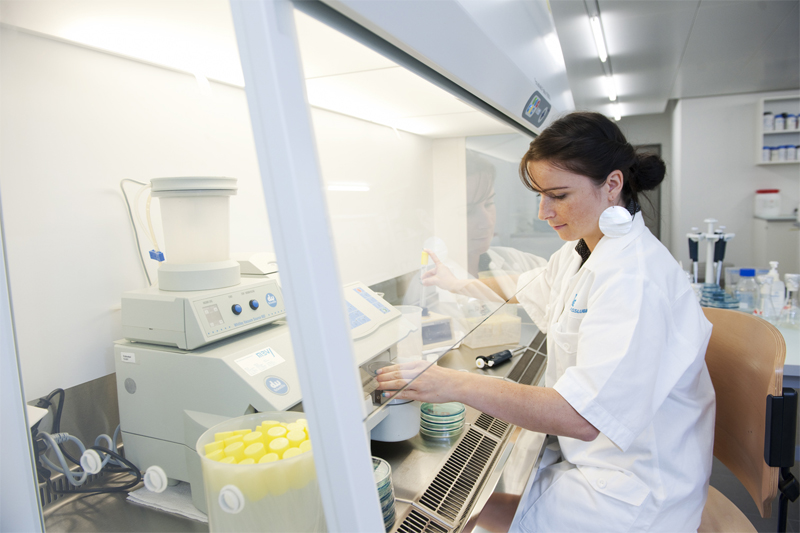

Blaser microbiology lab technician at work

Blaser microbiology lab

Sustainable Blasocut Bio-Concept

Blasocut 4000 Strong is a coolant out of the Blasocut line. The Blasocut products have an excellent human and environmental compatibility. The technology has been able to contribute to the robust process of machining, high productivity, and better machining quality. In today’s manufacturing world, it has become a global requirement for all manufacturing industries to contribute towards the environment. There is a high level of awareness about the ill effects brought in by many factors of industrialization. Sustainable technologies like the Blaser Swisslube Bio-Concept work in perfect harmony with nature. With the Blasocut Bio-Concept, emulsions need no tank side addition of bactericides. They stay inherently biologically stable. These emulsions have a unique way of maintaining the long-term bio-stability of metalworking fluid emulsions. The Bio-Concept uses an age-old law of nature whereby bacteria normally colonize the aqueous media immediately. To keep the emulsions stable, ideal conditions are created for the harmless primary bacteria. These bacteria, also present in drinking water, build up a naturally stable biotope where undesirable bacteria have no chance of propagating.

Making Customers Happy

The Tata Motors’ passenger vehicles plant in Pune is one of the most advanced manufacturing facilities in India. The facility has introduced many popular models like Indica, Indigo, Marina, Vista Manza, Zest, Bolt, and Nexon. Speaking on his company’s successful association with the automobile giant, Punit Gupta, Managing Director, Blaser Swisslube India, notes, “A happy customer is our main goal. At Tata Motors in Pune, the emulsion Blasocut 4000 Strong is still running great. Our specialists check and monitor the emulsion on a regular basis to control the vital parameters like pH, emulsion concentration and many more. We offer each customer a tailored monitoring plan for their central systems.”

“Customers like Tata do not just want a cutting fluid but are also looking for a competent and dependable partner to help organize and optimize their machine processes. With our committed team, we provide this partnership. The partnership with Tata, for instance, contributed to the robust process of machining, high productivity and better machining quality. The collaboration of 20 years is a result of trust and strong commitment from both sides to deliver the best and the safest to the industry and the environment,” he adds.

“Our people are always very excited to work with customers in exploring the possibility to exploit the full potential of machines and tools in the manufacturing process. Productivity, economic efficiency, and machining quality are factors that critically depend on the choice and the quality of the metalworking fluid. With us as a partner, one will get the Liquid Tool: the right coolant for their application, correctly used and monitored with on-site support by our specialists,” sums up Gupta.

Requirement : In 1998, Tata Motors in Pune was investing in high-performance technology for aluminum machining for car production. Thus, it was on a lookout for a competent partner that could fulfil its main requirement of a high-performance material removal and a reliable coolant system.

Solution : Blasocut 4000 Strong, a coolant out of Blaser Swisslube’s Blasocut line, which is still stable and running smoothly for 20 years now. The Sustainable Blasocut Bio-Concept technology has been able to contribute to Tata Motors’ robust process of machining, high productivity, and better machining quality.

There is a high level of awareness about the ill effects brought in by many factors of industrialization. Sustainable technologies like the Blaser Swisslube Bio-Concept work in perfect harmony with nature.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe