Propelling Towards Excellence

Mahindra Kandivali Plant is the mother plant of Mahindra Auto Sector that operates on the Product Unit Concept. There are six product units producing aggregates and vehicle—Axle, Body, Engine, Foundry, Transmission and Vehicle. Apart from vehicle production, the plant produces and supplies aggregates to the company’s other plants like Nashik, Chakan, Haridwar and Zahirabad, Igatpuri of Auto Division and also to Mahindra Farm Division.

Mahindra foundry

It is a Grey Cast Iron captive foundry, commissioned in the year 1971. It has a built-up area of 2.5 acre and a dispatch capacity of 15,000 metric tons. The company produces DI Cylinder Heads and Crank Case Castings which are considered to be one of the most difficult castings in the foundry industry. The Cylinder Heads constitute almost 80 percent of its production. The company is a Single Source for these casting products. Its customers are Auto Division, Farm Division, Power-all Gen-sets and Agri business. It also exports castings to Mitsubishi Tractors Japan as well as Mahindra USA.

-best-practices-F-img1.jpg)

|

Benefits at a glance

|

-best-practices-F-drw1.jpg)

Planet, People and Profit Problems

Foundry process flow comprises of many processes such as core making, moulding, melting, pouring and fettling, all integrated with each other. After analysing foundry’s capacity through Yamazumi, it was found that bottleneck was in the area of core making stage. Teams mapped the entire process for cellwise carbon footprint generation to realize the adverse effect on the planet and found that the core making stage is the second largest contributor of CO2 generation. Already focused CFT Team is working on the Melting Section which was highest Carbon Footprint Generator.

Associates’ fatigue was studied through scientific ergonomic tool ‘SSES’ (Simplified Safety and Ergonomics Study) and it was realized that there was high fatigue to associate due to the heat involved (300oC) in the Shell Core making stage.

Resolving the problem

M&M carried out a why-why analysis against each phenomenon like high cycle time, high CO2 emission and high fatigue to associates, and found the common root cause of ‘Exothermic Process’ that needs heat around 300o C for core curing process. Hence, a process had to be explored that didn’t require any heating.

Various options were considered: A core centre costed around `560 lakhs and the payback period was around five years; a multi-station machine costed `110 lakhs per annum and the payback period was coming to be 10 months. Resorting to these conventional ideas didn’t align with the company’s frugal approach as these would have led to discarding of the existing machines.

The team with a robust TPM approach, operation excellence and robust planning took up the challenge to convert the existing 35 years old equipment to Global Cold Box technology.

Cold Box process requires absolutely no heating. It’s a chemical bonding reaction which is carried out at ambient temperature against heating of the die upto 300o C earlier. Here, there is no fatigue to the associates working at that stage and it’s highly safe to operate.

Hurdles encountered

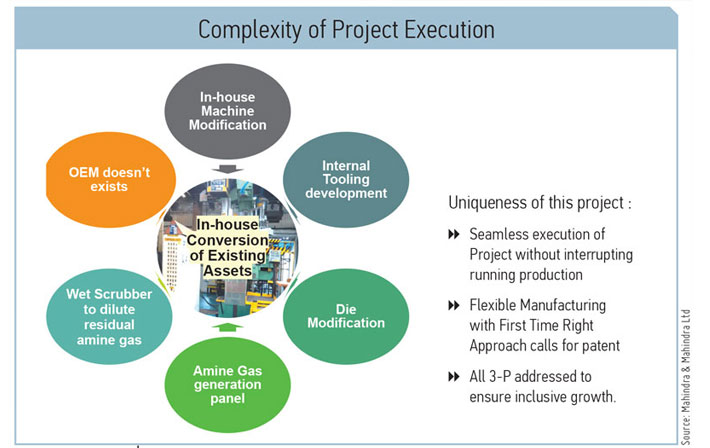

However, while implementing the project, the company had to tackle many issues and make modifications:

Machine Modification: Earlier machine was of open chamber type to support Die heating through PNG Gas but cold box core making process requires closed chamber to avoid Amine gas Leakages. The gas burner used for heating of the Cores is been converted into an Integrated Amine Purging unit required for the desired process.

Die Modification: Conversion of existing dies to suit Cold box where highly precise sealing is needed at the parting line

to ensure gassing and curing of cores.

Amine Gas Generation Panel: It’s highly unsafe to transport gaseous Amine so custom designed Amine Gas Generation Panel was installed to convert the liquid Amine to gaseous Amine used for gassing and purging of cores.

Neutralizing Residual Amine Gas: Gaseous Amine is highly dangerous to the environment. Hence, custom-designed water-based Scrubber unit was installed to neutralize residual Amine gas.

Efforts recognized

This was the first time in the foundry industry that an existing Shell box machine was converted into Cold box machine. Accomplishing this conversion under the theme of flexible manufacturing without a single day production loss and achieving productivity enhancement by 38 percent, depicts the true demonstration of Mahindra Rise Philosophy.

Amar Patil

DGM Foundry PU

Mahindra & Mahindra Ltd

Automotive Sector

patil.amar@mahindra.com

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe