Showcasing Ideas for Energy-efficient Metalworking

METAV 2022 in Düsseldorf, Germany is to be held on June 21-24, 2022. It will provide insights into innovative manufacturing technology and document the availability of technology for climate-friendly production.

Those looking to invest in climate-neutral manufacturing can now benefit from the advantages of new machine concepts that are to be showcased in METAV 2022. They can also minimize the payback time on investments in new machinery and equipment in the form of immediate energy savings and with the help of subsidies.

METAV 2022 will showcase the entire spectrum of production technology. The main focus is on machine tools, tools, accessories, measuring technology, surface, and computer technology for metalworking, software, machines, and systems for additive manufacturing, production systems, and components for medical technology. In addition, METAV 2022 will highlight specific solutions in four theme areas: Additive Manufacturing, Medical, Moulding and Quality. METAV 2020 had to be canceled due to the COVID pandemic and was held as a digital event in 2021.

Energy efficiency as a competitive advantage

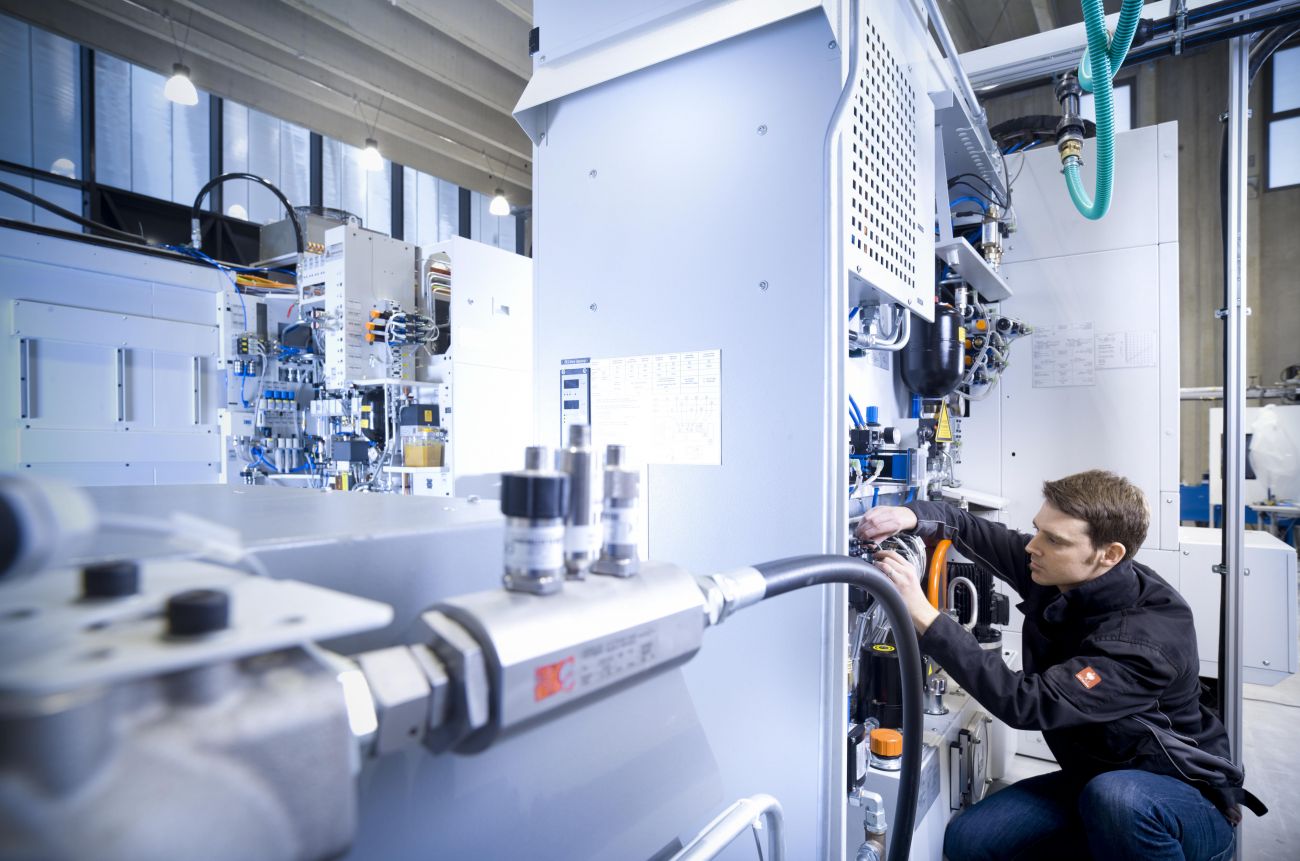

|

Thermography can help identify inefficient units, such as unregulated hydraulic systems. |

Around one-third of energy consumption in Germany is attributable to the manufacture of products. The International Energy Agency (IEA) sees energy efficiency as by far the most effective method of avoiding carbon emissions. However, anyone serious about improving the relationship between productivity and energy consumption also has to know where, how much and in what form energy is needed and consumed. For example: studies by RWTH Aachen University show that the auxiliary units responsible for the supply of cooling lubricant (coolant), cooling, and hydraulics are the largest energy consumers in machine tools. Together with the main spindle, they account for more than two-thirds of a machine tool's energy consumption, the scientists found. Manufacturing companies can achieve improvements not only by rebuilding existing systems, but also by constructing new systems with energy-efficient components.

Datron AG based in Mühltal, Hesse, is one such METAV exhibitor that focuses on energy consumption (alongside precision and performance) at an early stage in the development of its new machines. "Energy efficiency will be one of the most important selling points in the future," says a convinced Sven Kreusel, Head of Global Sales.

Meanwhile, Datron high-frequency (HF) spindles, for example, can manage micrometer-level precision and speeds of up to 60,000 1/min with a maximum power of 8 kW. This is about one-third of the energy required by conventional spindles. In addition, the company's engineers have set about eliminating energy-guzzling machine tool peripherals. According to Kreusel, this mainly involved replacing hydraulics with vacuum technology and using efficient, minimum-quantity cooling lubrication, which is less cost-intensive and takes up less space than conventional cooling lubricant systems.

|

The best way to maximize the effect of energy efficiency measures in new procurements, retrofits or similar projects is to plan them in from the outset, says Dr. Philipp Schraml, Managing Director of ETA-Solutions. |

According to Kreusel, it is still necessary to raise awareness of energy efficiency among users because they often underestimate or overlook the potential savings. A young generation of entrepreneurs has already internalized the idea of climate protection and is now asking the right questions. As a rule, however, the topic is usually the last to be brought up by interested parties and customers when the negotiations turn to acquisition costs and ROI (return on investment). "They are often pleasantly surprised when we then show them how they can save between 15,000 and 22,000 euros in energy costs per year, depending on the application," says the sales manager.

Generous financial support underutilized

"All the energy efficiency measures we propose are cost-effective," emphasizes Dr Philipp Schraml, Managing Director of ETA-Solutions, a consulting firm based in Bensheim near Darmstadt. This is due to the potential cost savings, but also to the support measures which are available and which reflect the current political relevance of the topic. Schraml points out that, in principle, money is available for all kinds of measures and for different budgets from various regional or European funding sources. These include federal funding for energy audits, or the energy and resource efficiency program. Even the consultation process qualifies: “Our work is practically cost-neutral,” says the expert, “because we always manage to save both our own costs and then some on top, even in the case of smaller and non-investment measures.”

It may, therefore, seem all the more surprising that, according to the Institute for Energy Efficiency in Production (EEP) at the University of Stuttgart, only one in four eligible companies has so far taken advantage of the subsidies available. Business experts suspect that the reasons for this lie in the lack of funding transparency and in companies’ fears of complicated application procedures.

Schraml sees a different problem: “We find that many companies, especially smaller ones, simply lack the expertise and staff needed to identify and tackle sensible energy efficiency measures.” Upstream and downstream processes are rarely analyzed, there is no communication between different trades, and too little advice is provided on energy efficiency. The issue is exacerbated by the initial costs which the process of collecting energy data also incurs. For ETA-Solutions, the first step is therefore always to create transparency and a clear understanding of the overall context. Only then does the consulting company develop proposals for appropriate measures – in collaboration with the client. The third step is to make multiple use of the energy that is used for production – for heating and warmth and for efficient building and plant cooling. The most cost-effective way to implement energy efficiency measures in new procurements, retrofits, or other projects is to plan them from the outset. Solid estimates of the potential energy savings are prerequisites for funding requests.

|

Sven Kreusel, Head of Global Sales at Datron AG, is convinced that energy efficiency will be one of the key selling points for products in the machine tool sector in the future. |

Action profiles from research

Practice-oriented research projects aim to create transparency and introduce new ideas. ETA-Solutions is a spin-off from the Institute for Production Management, Technology and Machine Tools (PTW) at TU Darmstadt. The interdisciplinary research group ETA (Energy Technologies and Applications in Production) including the ETA Factory research laboratory was established in 2016. The Federal Ministry for Economic Affairs and Energy funded the ETA Transfer project. The effects of specific energy efficiency measures were analyzed and documented in cooperation with well-known companies such as Trumpf and Bosch-Rexroth. ‘Action profiles’ drawn up for aspects such as control cabinet, machine, and system cooling or heat recovery attest to savings of 25 to 85 percent. The profiles are available at https://eta-transfer.de. They describe the individual measures, quantify the proven savings and payback period, and also indicate which funding options are available.

At the end of the ETA Transfer project, many participants – including scientists and skilled workers – were surprised at just how great the effects even of small or non-investment-based changes can be. In order to achieve significant energy savings, it was sometimes enough to replace only one small piece of equipment or to consistently shut down the machine during breaks in processing. Raising energy efficiency involves the deployment of appropriate machines and components, but also using them in organizationally energy-conscious ways. It pays to raise employees’ awareness of the importance of shutting down the machine at the end of the shift or over the weekend – provided the machine's ramp-up behavior permits this. In the future, however, machines should be able to organize this themselves. The system control will then switch the machine and its ancillary units automatically to energy-saving mode, both during processing breaks and whenever an empty loading unit is detected, for instance.

A question of corporate culture

Many companies that are subject to mandatory energy audits come to ETA-Solutions, says Schraml. A number of small and medium-sized companies also decide they ‘want to do their part’ or even strive to become carbon-neutral factories. "These are our favorites," admits Schraml. However, the path to greater energy efficiency and carbon-neutral production is by no means dependent on the size of the company, but rather on its corporate structure and culture. It, therefore, quickly becomes apparent whether the issue is part of a sound sustainability strategy that also includes the employees. In this case, the path to reducing carbon emissions or even to creating a climate-neutral factory is usually given a high priority by the company management and is consistently implemented as a climate protection measure.

Image Source: VDW

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe