ROOTED IN LEGACY

As a trusted partner in metal alloy solutions, AMPCO METAL has assisted clients in resolving technical issues with highly engineered alloys made from readily available materials. With a legacy and a strong portfolio that differentiates it from its counterparts, the company is all set for tremendous growth in the coming years.

Since 1914, AMPCO METAL has collaborated with industry partners from various market segments to develop solutions for a range of applications, including friction and wear resistance, corrosion resistance, and heat and electrical conductivity.

AMPCO METAL INDIA PVT LTD, a wholly-owned subsidiary of AMPCO METAL SA, headquartered in Switzerland, began operations in Pune in 2012. It now serves customers in India for niche applications such as tube bending toolings, tube forming rolls, and material for deep drawing dies end forming punches in the Forming industry. It is an ISO 9001:2015 certified company with a warehouse and service center in Chakan, Pune, where materials are stocked according to customer needs.

AMPCO METAL INDIA PVT LTD, a wholly-owned subsidiary of AMPCO METAL SA, headquartered in Switzerland, began operations in Pune in 2012. It now serves customers in India for niche applications such as tube bending toolings, tube forming rolls, and material for deep drawing dies end forming punches in the Forming industry. It is an ISO 9001:2015 certified company with a warehouse and service center in Chakan, Pune, where materials are stocked according to customer needs.

Sharing more about the company, Tushar Pawar, National Head, AMPCO METAL INDIA PVT LTD, says, “Our state-of-the-art facility at Pune includes a fleet of CNC turning centers and vertical machining centers, turn-mill machines, wire cutting machines, a heat treatment facility, automatic sawing machines, along with conventional lathes and milling machines for precision components manufacturing.

We are also equipped with CMM (Coordinate Measuring Machine) and other sophisticated inspection equipment for critical measurement and quality control.”

Drawing on the expertise

For over a century, AMPCO METAL has pioneered and produced the ‘best metal solutions’ for the world’s products, applications, and industries. A manufacturer of specialty copper alloys under the brand names AMPCO® and AMPCOLOY® and a forerunner in developing aluminum bronze alloys, the company continues to engineer premium products for critical applications with its well-known AMPCO® product line to this day. Its high-quality, high-property, and uniquely hard metal range is trusted worldwide for its broad use.

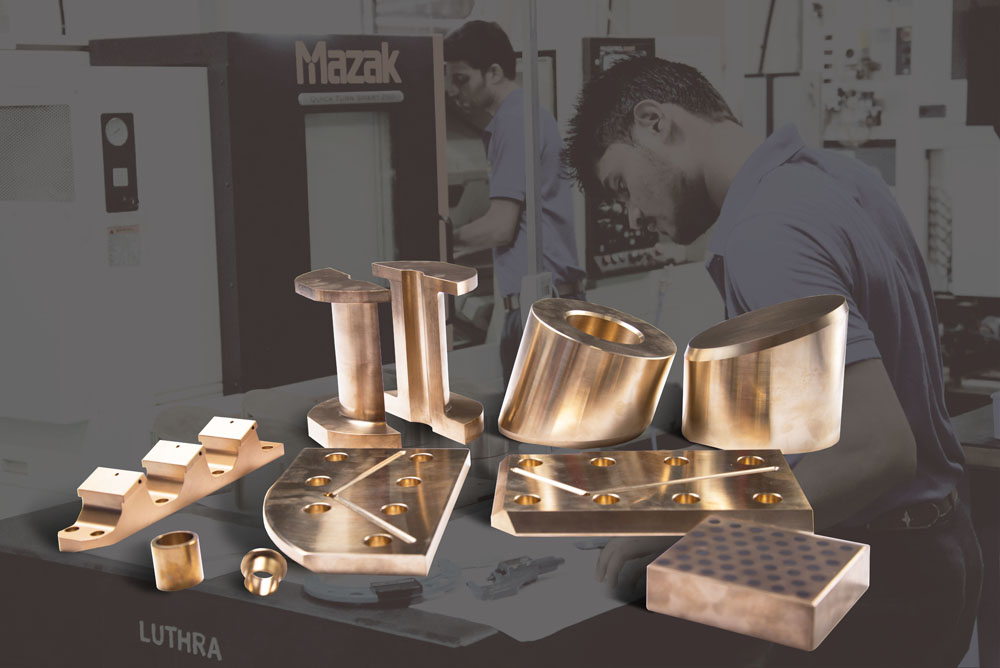

Machining Facility

“AMPCO® Aluminum Bronze extends to food-approved applications through alloys such as AMPCO® 8, AMPCO® 18, and AMPCO® M4,” adds Pawar. “Our high hardness materials AMPCO® 21, AMPCO® 22, and AMPCO® 25 are used where high compressive forces are in play and critical for the end product’s quality.” In addition, AMPCOLOY® High Copper alloys are engineered with exceptional conductivity, high strength, and unique wear characteristics, delivering higher lifetime, quality, and performance with cleaner trace elements. These materials are used in critical applications that require both conductivity and mechanical properties, such as plastic molds and resistance welding.

A manufacturer of specialty copper alloys under the brand names AMPCO® and AMPCOLOY®, and a forerunner in developing aluminum bronze alloys, the company continues to engineer premium products for critical applications with its well-known AMPCO® product line to this day.

Competitive advantage

AMPCO METAL produces high-performance aluminum bronze with a patented technology known as MICROCAST®. This manufacturing process, which is based on the exclusive magnetic steering (Magneto-Hydro-Dynamic) at the casting furnace, produces extremely fine grain and uniform microstructure, promoting excellent dispersion of the alloy chemical elements for consistency, quality, and durability.

Pawar explains, “Through our patented production process, AMPCO® M4 has mechanical properties far beyond the range of conventional commercial Nickel-Aluminum bronzes. The increase in the Al and Fe content in the alloy results in a material in which the hard gamma 2 phase is present. By expert metallurgical control, this hard constituent is uniformly distributed, giving the alloy its unique performance qualities and the ability to resist wear.”

AMPCO® M4 is best suited for higher technical properties at elevated temperatures and corrosion resistance. It is also ideal for gear bearings and bushings, bending dies (shoes and mandrels) for the Tube Bending industry, gear wheels, and wear/guide plates.

AMPCO® M4 is best suited for higher technical properties at elevated temperatures and corrosion resistance. It is also ideal for gear bearings and bushings, bending dies (shoes and mandrels) for the tube bending industry, gear wheels, and wear/guide plates.

AMPCO® Wear Resistant Components

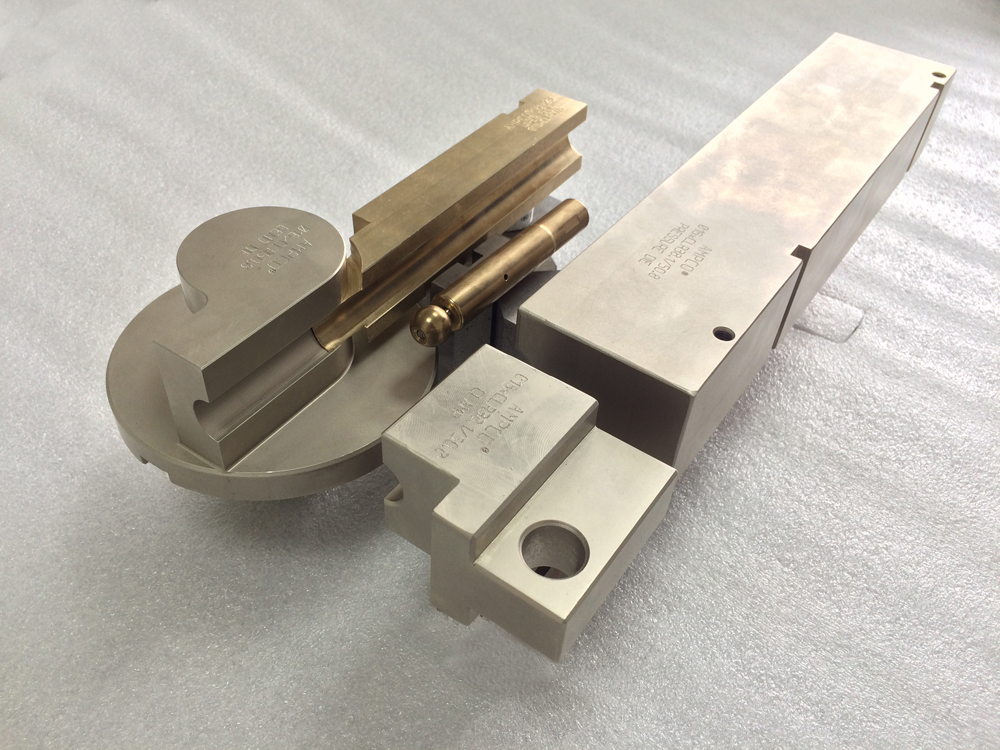

Tube Bending Consumables

Tapping the opportunity

AMPCO METAL serves customers in the Aerospace, Automotive, General Engineering, Marine, Metal Processing, Oil & Gas, Chemical, Plastic Processing, Resistance Welding, and Steel Mill industries. Sensing prospects in the country, he confirms, “Yes, there are a lot of opportunities in the Indian market. The current global scenario has provided a golden opportunity for Indian industries. ‘Make in India’ strategy is a great opportunity for us. We must act on it and grab it.”

He further states, “Looking at the current international situation, we must work on the success of ‘Aatmanirbhar Bharat’. The industries around the world depend on the Automotive industry, and the Indian Automotive industry has grown to become one of the largest in the world among all the segments. Looking at all the above scenarios, India has a great business opportunity in the coming days.”

Showcasing versatility

To further extend its reach, the company plans to introduce Tube Bending tooling sets as a new product at the forthcoming International Machine Tool & Manufacturing Technology Exhibition (IMTEX). It has developed in-house capabilities for designing, supplying, and testing the tube bending die set. “This is exciting news for tube bending machine manufacturers and users in the Aerospace industry, exhaust tube manufacturers, hygienic tube producers, furniture manufacturers, etc. All the tube benders always seek lower cost-per-bend, and AMPCO METAL ensures the same. AMPCO® Tube Bending tooling greatly benefits tube bending of stainless steel and titanium tubes. It increases the product quality and life of the production tooling,” shares Pawar.

To further extend its reach, the company plans to introduce Tube Bending tooling sets as a new product at the forthcoming International Machine Tool & Manufacturing Technology Exhibition (IMTEX). It has developed in-house capabilities for designing, supplying, and testing the tube bending die set. “This is exciting news for tube bending machine manufacturers and users in the Aerospace industry, exhaust tube manufacturers, hygienic tube producers, furniture manufacturers, etc. All the tube benders always seek lower cost-per-bend, and AMPCO METAL ensures the same. AMPCO® Tube Bending tooling greatly benefits tube bending of stainless steel and titanium tubes. It increases the product quality and life of the production tooling,” shares Pawar.

Emphasizing that IMTEX FORMING is one of the most notable exhibitions in India to explore and connect with the audience, he states, “It is the point of contact to connect with the entire industry in India and plays a critical role in the development of the metal forming industry.”

Looking forward to leveraging the expo, he mentions, “Creative engineers worldwide choose AMPCO® Bronze alloys to broaden their manufacturing options when forming high-value materials such as stainless steel or low carbon steel, titanium, and other exotic materials. And IMTEX FORMING helps AMPCO METAL to demonstrate such solutions to the potential users and find opportunities in the applications which are new and challenging.”

He continues, “AMPCO METAL’s solutions are a real game-changer for the Forming industry. We will be showcasing a range of tube bending tools, tube forming and welding rolls, deep drawing dies, high-wear resistant parts, resistance welding electrodes, etc.”

AMPCOLOY® High Copper alloys are used in critical applications that require both conductivity and mechanical properties, such as plastic molds and resistance welding

Envisioning growth

With its experience and technical competence, the company is strengthening its position as a dependable partner in creating metal solutions for its customers. With the help of its teams of highly-specialized experts in specific fields, AMPCO METAL consults directly with the customers to help realize their specific material needs.

He further claims, “MICROCAST® technology, this intermetallic compound is unique in AMPCO® alloys and differs from commercial aluminum bronzes. This gives AMPCO® alloys a fine and uniform grain size, differentiating them from other standard products. Looking at our strengths, we see tremendous growth in the coming years for our solutions.”

Sovan Tudu

Sub-Editor

Magic Wand Media Inc

Sovan.tudu@magicwandmedia.in

Source: AMPCO METAL INDIA PVT LTD

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe