CERATIZIT Presents New Waterjet Nozzle HyproJET Portfolio

Mamer, Luxembourg – CERATIZIT S.A. sets new standards for quality and durability by presenting the HyproJET portfolio of waterjet nozzles for smooth cuts thanks to waterpower. Waterjet cutting, recognized as a dependable alternative to conventional cutting processes, works as simply as it is effective: the cutting head directs a fine jet of water at a high pressure of up to 6,000 bar with a jet diameter of 0.38 to 1.02 millimeters. The material particles close to the surface are cut off without any heat being introduced into the material during this stress-free cutting process. This process is ideal for temperature-sensitive and thick materials with complex geometries.

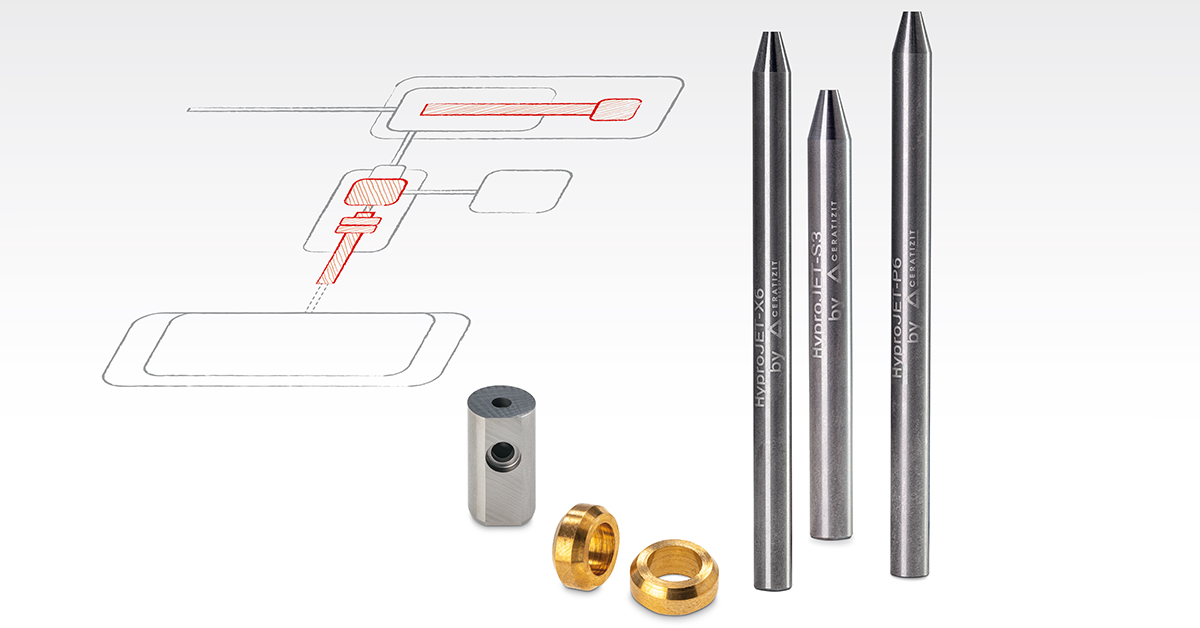

Water jet cutting has a wide range of applications, which means it can be used by a wide range of users for a wide range of different needs. Mesut Goksu, Segment Account Manager, CERATIZIT, states, “We developed our HyproJET range with three standard water jet nozzles to meet these needs: narrow hole tolerances, perfect cutting, and radial run-out accuracy to ensure precise working results.” The HyproJET X6 is a high-performance tool with improved abrasive material and air flow in the nozzle and a unique design for cutting even the most difficult materials. For standard applications, the company offers the HyproJET P6, which stands out due to its optimal price-performance ratio. The S3 standard water jet nozzle is an excellent choice for anyone looking for high-quality results at a low cost. All nozzles are suitable for modern cutting head systems and support automatic centering during assembly.

Image Source: CERATIZIT S.A.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe