COLLABORATING FOR PROGRESS

The industry and academia bond can play a pivotal role in ushering in innovation and economic growth. Their collaboration offers room for academia to contribute its research and knowledge, while the industry can provide expertise, experience, and opportunities for the other to progress. Cognizant of the fact that the duo together can work wonders, IMTMA provides a platform for them to connect with each other during IMTEX.

Every IMTEX, IMTMA offers Industry-Institute (i2) Academia platform for industry professionals and institutes to join forces that can bring in technological advancements, enhanced capabilities to manufacture high-tech products, increased product diversity, and reduction in imports.

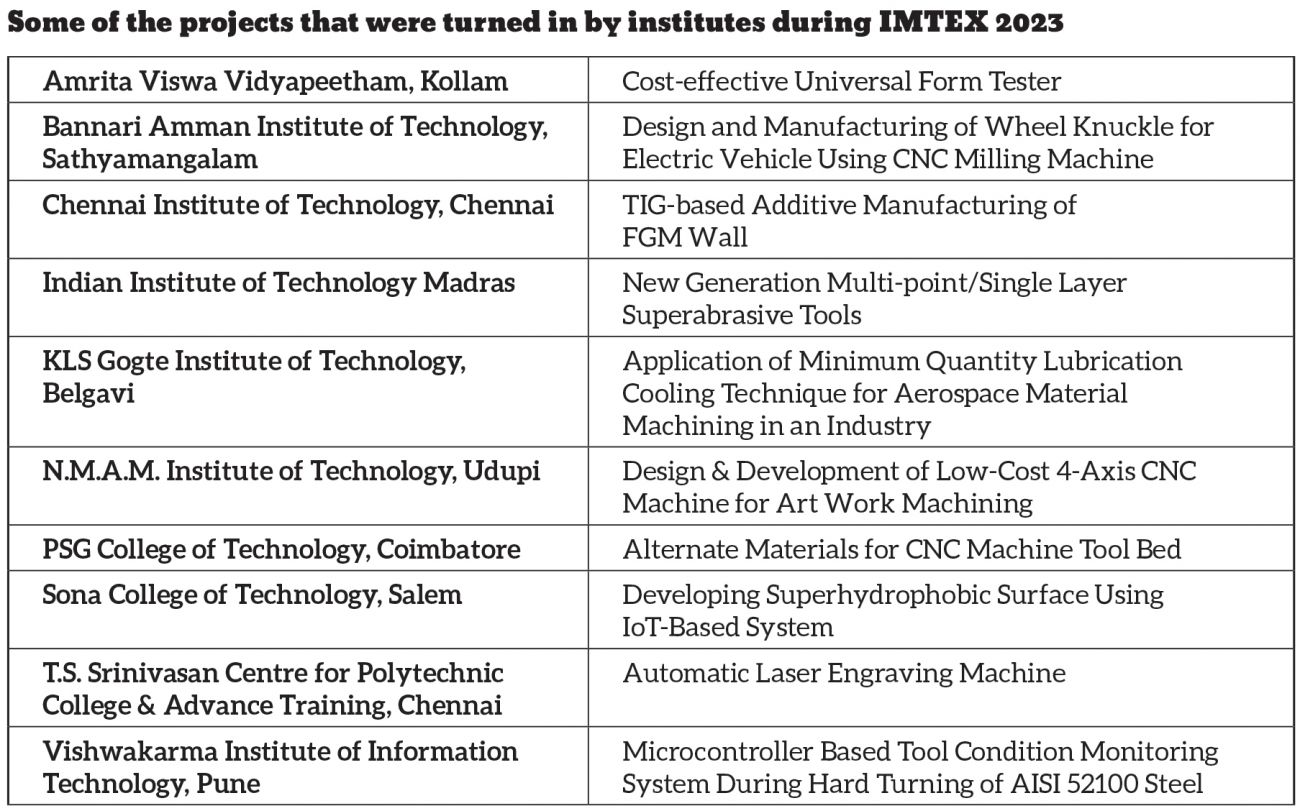

In keeping with tradition, IMTEX 2023 & Tooltech 2023 and Digital Manufacturing 2023 welcomed 22 institutes, including IITs, to present their R&D capabilities in the metalworking arena to the manufacturing fraternity gathered during the event and understand the requirements of the industry for them to be future-ready.

Some of the participating institutions included Amrita Viswa Vidyapeetham (Kollam) - Cost Effective Universal Form Tester; Indian Institute of Technology Kanpur (Kanpur) – Adaptive gain tuning for active damping of machine tool vibrations; KLS Gogte Institute of Technology (Belagavi) - Application of minimum quantity lubrication cooling technique for Aerospace material machining in an industry; and SSN College of Engineering (Chennai) - Ballistic performance of Aluminium 6061-T6 targets with ‘Bio-inspired pattern’ and internal grooves.

Inspiration galore

Harshit Gawda TN, Reva University (Bangalore), explained, “We have developed a manufacturing technique with aluminum alloy (Al 7075) with a mixture of beryl (6%) and graphene (2%) to increase the stiffness and lifespan of the metal. This can be used in the automotive industry for manufacturing outer body parts.”

(2%) to increase the stiffness and lifespan of the metal. This can be used in the automotive industry for manufacturing outer body parts.”

V Adesh, Sona College of Technology (Salem), shared, “Our project is Developing Superhydrophobic Surface (coating kit) using IoT-based systems, by using an acid erosion method with an ultrasonic cleaner, making it a water-repellent surface. This will be used in Aerospace, Automobile, and other industries. We have received a grant of `15 lakh from the MSME Department, GoI through this project to set up a small business.”

Trilochan Nanda, Ph.D. scholar, IIT Madras, revealed, “We are showcasing New Generation Multi-Point/Single Layer Superabrasive tools. We have developed our own tools through modifying commercially available (diamond) tools; they will directly go for stock removal processes up to 5 to 10 mm.”

|

To encourage their engineering talents, a competition was arranged for the young innovators in the Academia Pavilion, where budding engineers showcased their projects targeting to improve engineering processes. Out of the 22 showcased projects, 5 innovative works received cash awards and certificates |

Brilliant minds awarded

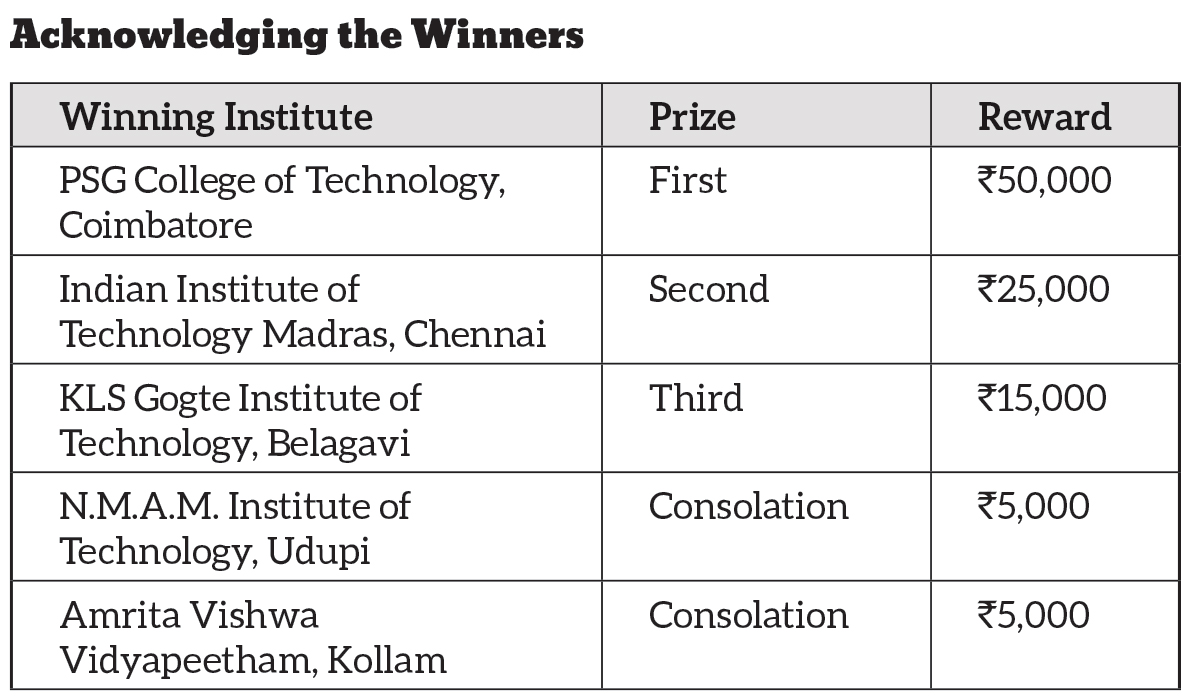

To encourage their engineering talents, a competition was arranged for the young innovators in the Academia Pavilion, where budding engineers showcased their projects targeting to improve engineering processes. Out of the 22 showcased projects, five innovative works received cash awards and certificates.

The team from PSG College of Technology, Coimbatore, bagged the First prize worth `50,000 for their project titled ‘Alternate Material(s) for CNC Machine Tool Bed’. The Second prize worth `25,000 was won by the students from the Indian Institute of Technology Madras, Chennai, for their project titled ‘New Generation Multi-Point/Single Layer Superabrasive Tools’. The Third prize worth `15,000 was awarded to the students from KLS Gogte Institute of Technology, Belagavi, for their project titled ‘Application of Minimum Quantity Lubrication Cooling Technique for Aerospace Material Machining in an Industry’.

Two consolation prizes each worth `5,000 were given to teams from N.M.A.M. Institute of Technology, Udupi, for their project titled ‘Design & Development of Low-Cost 4-Axis CNC Machine For Art Work Machining’ and Amrita Vishwa Vidyapeetham, Kollam, for their project titled ‘Cost Effective Universal Form Tester’.

The recent i2 Academia event was a resounding success as industry stakeholders took a keen interest in the projects presented by participating institutes. The institutes, in turn, were equally eager to learn as much as possible from the latter. Such synergy is poised to usher in technological advancements and bridge the gap between the two entities, creating a skilled workforce that can effectively meet the demands of the future.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe