Modular Drilling with Solid Carbide Performance

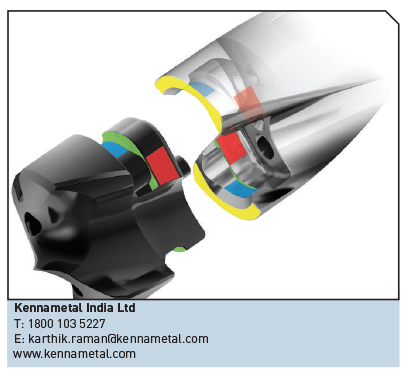

KenTIP FS is a perfect combination of a solid carbide and an indexable drill.

After having received an overwhelming response to KenTIP modular drill in the past decade, Kennametal has launched its upgrade - KenTIP FS, which is capable of drilling in steel, stainless steel and cast iron materials and has the parameters of a high-performance solid carbide drill.

Following are the features of KenTIP FS that make it a one-stop solution for substantial cost savings and process simplifications on the shop floor.

- The modular drilling system covers a 6–26 mm diameter range and up to 12 x D drilling depths.

- Applicable in steel, stainless steel, and cast iron.

- The KenTIP FS is available in 3-point geometries, 3 high-performance grades and 3 different shank styles.

- Full solid carbide circumferential insert design: Ensures less holder wear even in unstable cutting conditions.

- Multi coolant capability: Ensures at least 40 percent higher coolant flow to the cutting edge, which maximizes tool life.

- Fast flow: The flute design plus polishing ensures obstruction free chip flow even in long chipping materials and deeper holes. Thus it helps in less holder washouts, high process safety, and enhanced tool life and performance.

- Intelligent Interface design: The advanced patented intelligent interface ensures highest rigidity clamping. It allows less stress peaks and radial loads in the interface, thereby promoting high feed capability. Retention lock prevents insert pullout.

- Increased feed capabilities by up to 15 percent: Increases pocket life through lower stress peaks, less movement, less contact with chips and workpiece.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe