PROPELLING MACHINE TOOLS AND MANUFACTURING GROWTH

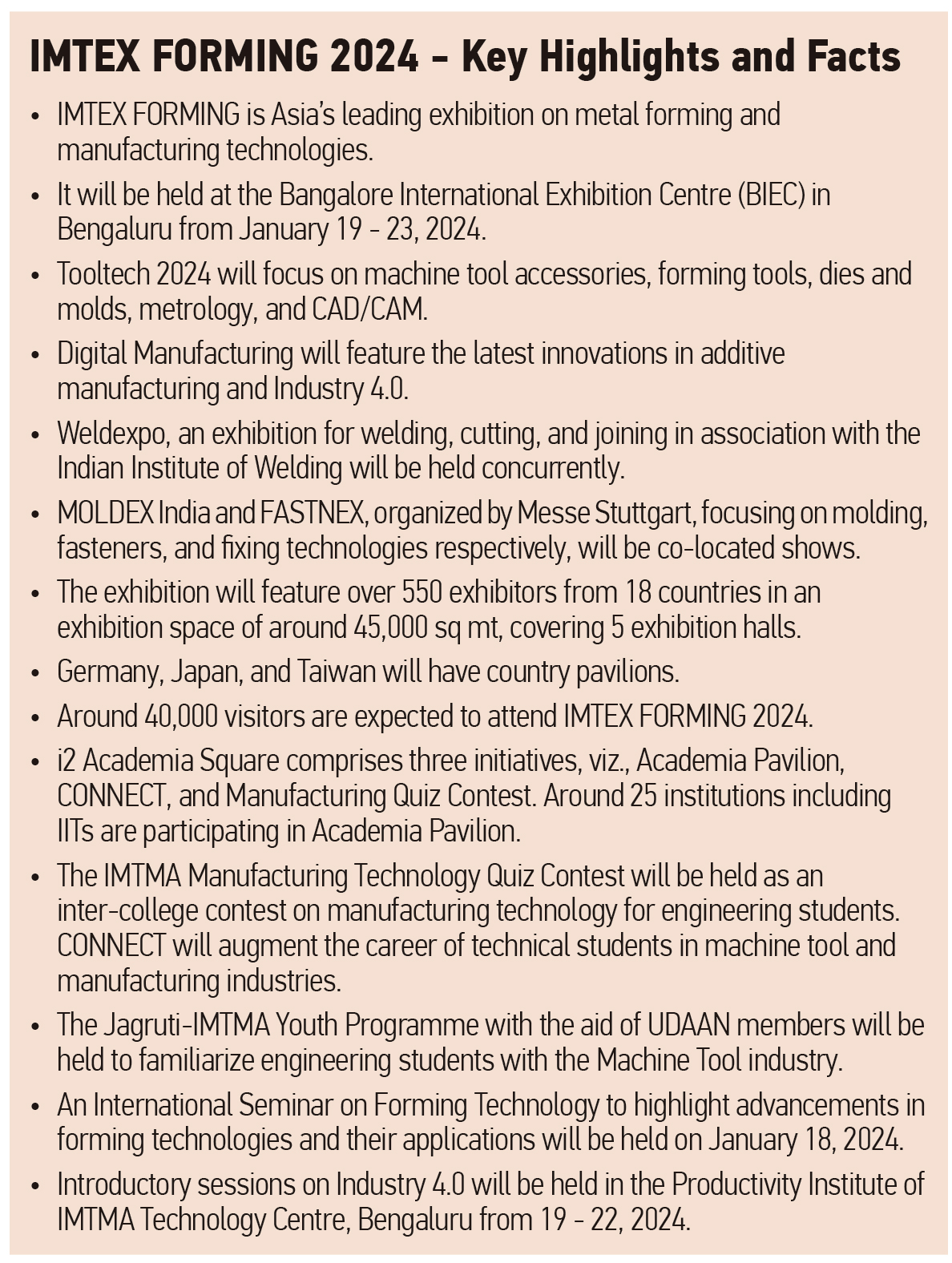

IMTMA’s flagship exhibition on metal forming technologies IMTEX FORMING is to feature over 550 exhibitors from 18 countries as it gets underway at Bangalore International Exhibition Centre (BIEC), Bengaluru, from January 19 – 23, 2024.

The Indian Machine Tool industry, as part of the Capital Goods sector, has performed well in 2023 and is looking forward to improving its position in 2024 and beyond. Consumption of machine tools in India during FY 2022-23 increased by 55 percent, reaching about `24,500 crore (around US$3 billion).

Among metal working machine tools, the country’s Metal Forming sector, with a market size of around `5,300 crore (about US$646 million) in FY 2022-23, has been doing well with new trends entering the market. Compared to the previous year, metal forming production, which was around `2,100 crore (about US$256 million) in FY 2022-23, is expected to grow at a compound annual growth rate of around 10 - 15 percent in the next 3-5 years.

For Indian Machine Tool Manufacturers’ Association (IMTMA), traditionally, the new year starts with its flagship exhibition IMTEX. In 2024, it is no exception and IMTEX FORMING 2024 is back with its glory. In terms of size and scope, IMTEX FORMING 2024 has grown immensely, expanding in size by around 80 percent in comparison to its previous edition, and with many new segments to showcase for its visitors.

The exhibition portfolio has expanded with Weldexpo as a concurrent show alongside Tooltech and Digital Manufacturing. Messe Stuttgart India is organizing MOLDEX India and FASTNEX as co-located shows. The Indian Institute of Welding India is organizing an International Congress from January 22-24, 2024.

As a bigger and more comprehensive exhibition for the metal forming and manufacturing industries in India, IMTEX FORMING 2024 is expected to make waves.

|

Compared to the previous year, metal forming production, which was around `2,100 crore (about US$256 million) in FY 2022-23, is expected to grow at a compound annual growth rate of around 10 - 15 percent in the next 3-5 years. |

Trends in focus

At IMTEX FORMING, exhibitors are to showcase a range of technologies, such as:

- Fiber laser machines that employ face recognition technology to identify the operator and load their preferred language and privileges; precision levelers for metal parts, sheets, and plates, and pick and place units; accessories for mechanical or other presses for loading flat blanks in tools;

- Servo presses, a revolutionary leap in press processing technology that further improves productivity; machine production monitoring systems for viewing collected and processed data and monitoring through a 3D model of the factory layout; and 3D printing solutions for building complex, mission-critical parts in industries;

- Die forging hammer technology, a significant improvement over conventional hammer drive systems; conveyorized belt grinding machines for precision deburring of flat punched and fine blanked parts like clutch plates; and advanced waterjet cutting and cleaning solutions;

- Reverse engineering solutions for helping manufacturers with scanning, designing the part, and creating prototypes; plasma cutting power for optimal and reliable cutting results with easy operation and low investment and operating costs; and friction welders that come with the ‘Cycle Time’ challenge;

- Compact drive technology; servo robotic spot welding guns; spider/cross, an essential steering component; CNC press brakes and shears; metal scrap recycling; AM system software, a software platform to manage orders, automate laborious tasks, and scale one’s operations; tube bending solutions; thermal cutting solutions; cobot welding solutions; angle cutting machines; vibration transmission control systems; friction welders to provide the fastest welds; and slitting lines for minimizing tooling change time;

Role of metal forming

“All commercial and consumer goods manufactured by various industries rely on components that are formed in press shops, roll-forming facilities, etc. The Indian Machine Tool industry is taking steps to build knowledge and capability for building lighter and stronger components and encourage sustainable manufacturing practices,” said Rajendra S Rajamane, President, IMTMA.

“The Metal Forming industry builds products and components for safer vehicles and efficient appliances. With the growing size and capability, the time is apt for Indian manufacturers to compete with the global players to make significant advancements in the industry and provide cutting-edge solutions for the world. IMTEX FORMING 2024 is the best platform to hasten this process,” said Jibak Dasgupta, Director General & CEO, IMTMA.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe