WITH THE CUSTOMER IN MIND

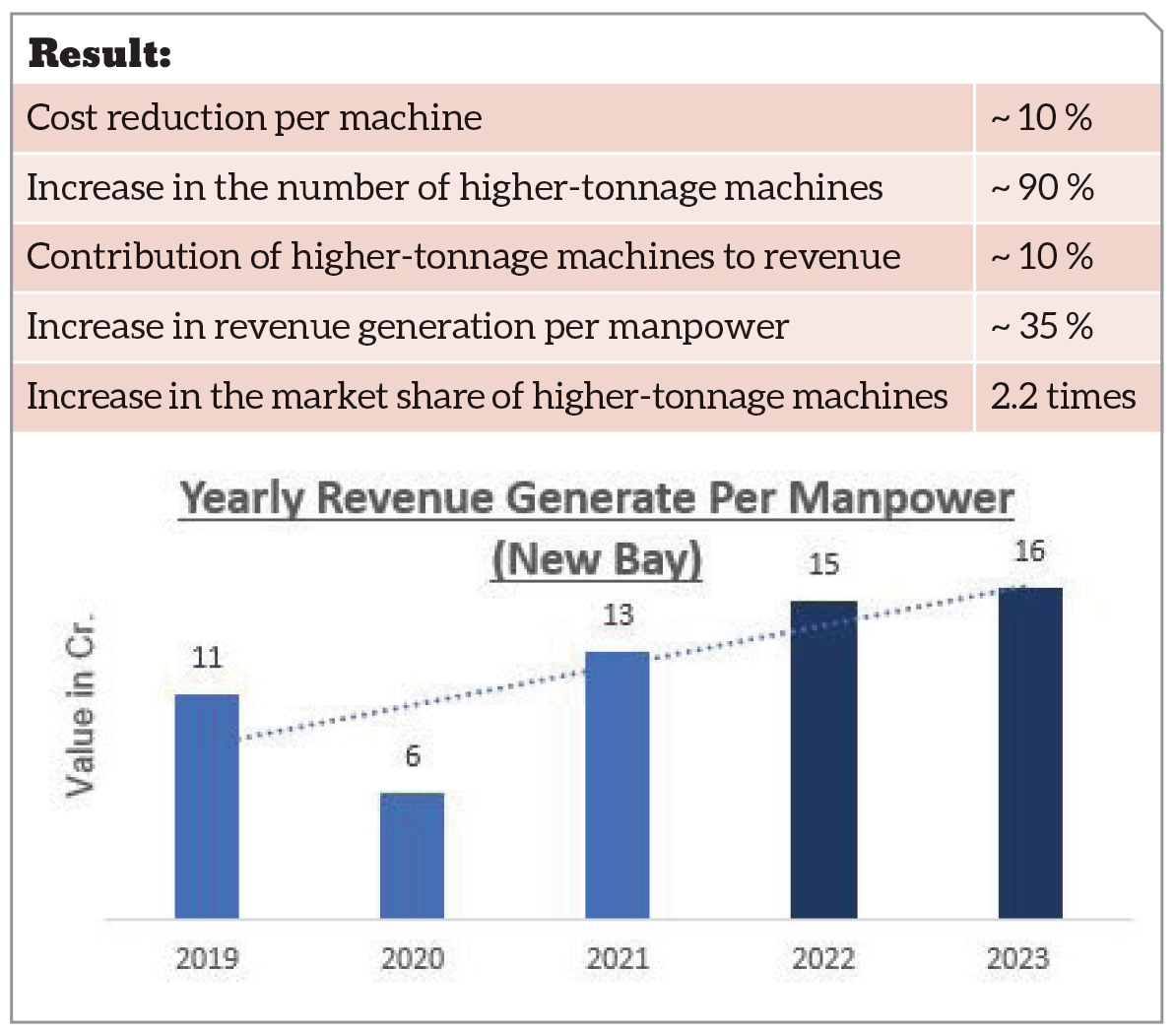

Higher-tonnage injection molding machines are a promising product offering from Milacron India Pvt Ltd (MIPL). However, the company faced challenges from competitors in the market, and in order to become a market leader as an original equipment manufacturer (OEM) for higher-tonnage injection molding machines, it was essential to provide high-performing products at competitive costs while maintaining the best quality. A strategic approach was thus required to overcome the challenges encountered. Thus, MIPL implemented a systematic plan to meet customer requirements and address these challenges effectively.

In our endeavor to close the gap between our customers and ourselves, we initiated a comprehensive customer survey. Through this survey of higher-tonnage machines, we gained valuable insights that highlighted the significant area of improvement within the clamp unit of our plastic processing machines. This feedback from our customers provided us with a clear direction.

As a prominent manufacturer of tailor-made plastic processing machines, it is crucial for us to adapt to the changing market conditions and meet the evolving demands of our customers. We recognize the importance of delivering machines on time and ensuring performance. To achieve this, we had to curbthe cost and gain an edge over our competitors.we had to curb the cost and gain an edge over our competitors.

Solution generation, innovation, and complexity

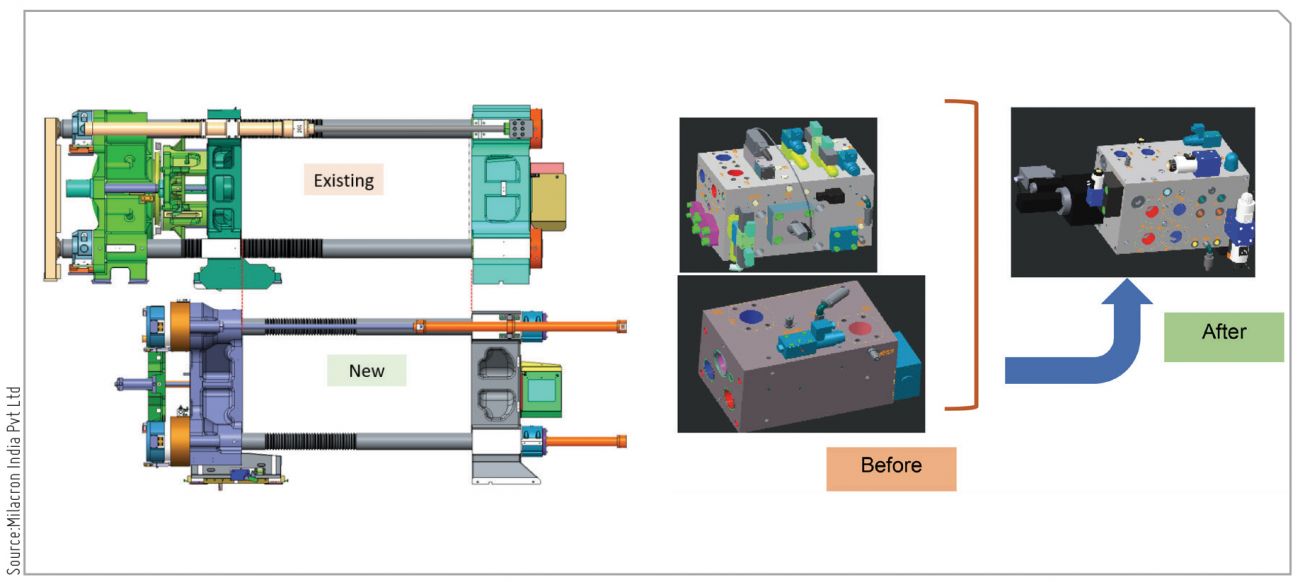

The customer survey provided us with valuable insights and feedback, allowing us to focus on the clamp unit to align with them.

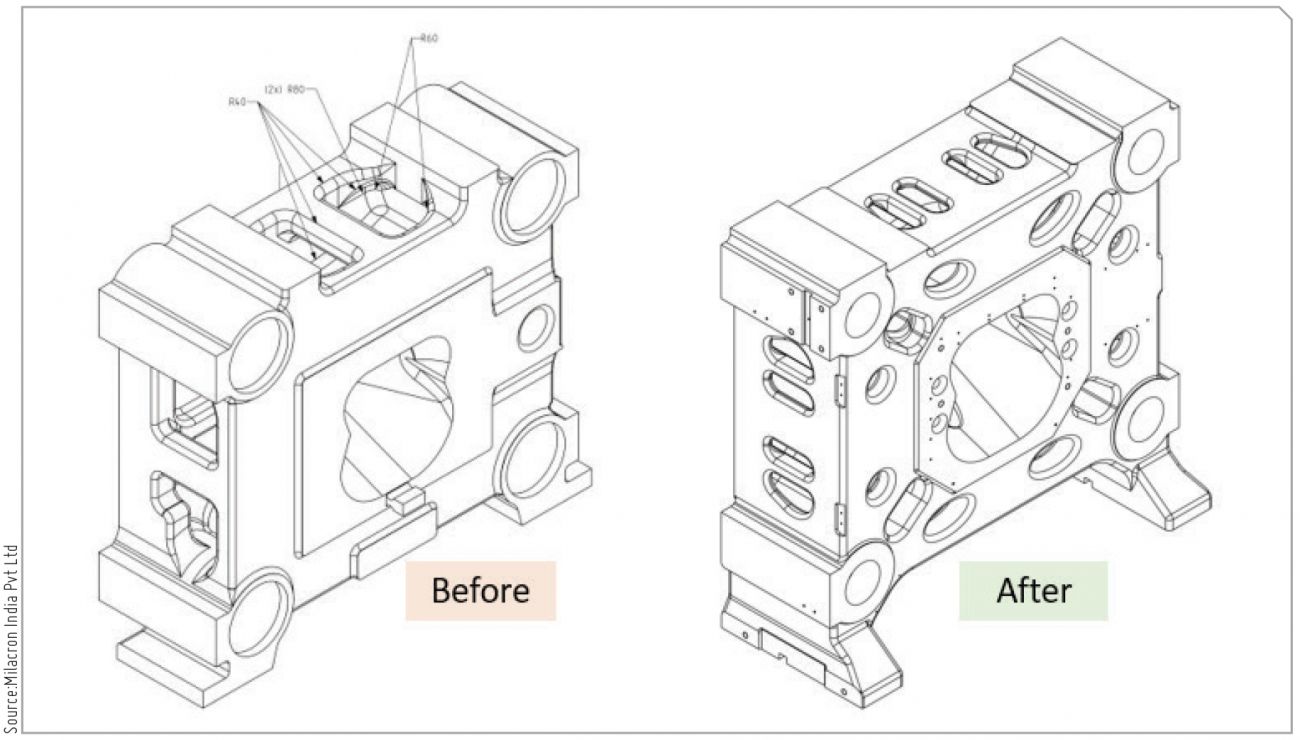

- Material Selection: We evaluated the materials for conceptual weight reductions that led to improvement in closing speed, resulting in cost reduction without compromising functionality and performance. We also looked for alternative materials that could provide similar or better properties at a lower cost.

- Design for Manufacturability (DFM): We optimized the clamp unit design for efficient manufacturing processes and considered factors such as ease of machining, reduced scrap or waste, and ways to minimize the need for specialized tooling or processes. This helped lower production costs.

- Value Engineering: A value engineering analysis of the clamp unit was conducted to identify areas where cost savings could be achieved. This involved evaluating the function of each component and exploring alternative designs or manufacturing methods to reduce costs while maintaining performance.

|

During validation, we covered all real-world operating conditions and the anticipated loads and constraints in the defined application. The results were found satisfactory in all segments. |

-

Supplier Collaboration: We thought it was crucial to engage with suppliers and manufacturing partners to explore cost-reduction opportunities. We sought their input and expertise in identifying alternative materials, design modifications, or process improvements.

-

Design Failure Mode and Effects Analysis (DFMEA): Through DFMEA, we proactively identified and mitigated potential failure in the design stage, ensuring high product quality and customer satisfaction.

-

Continuous Improvement: A system was established for ongoing cost optimization and continuous improvement. The production data was regularly monitored and analyzed. Feedback from customers and suppliers were regularly sought and industry trends explored to identify further opportunities for cost reduction in the clamp unit.

|

The outcome exceeded MIPL's expectations with an impressive reduction of an average of 22% without compromising the machine’s performance and specifications. |

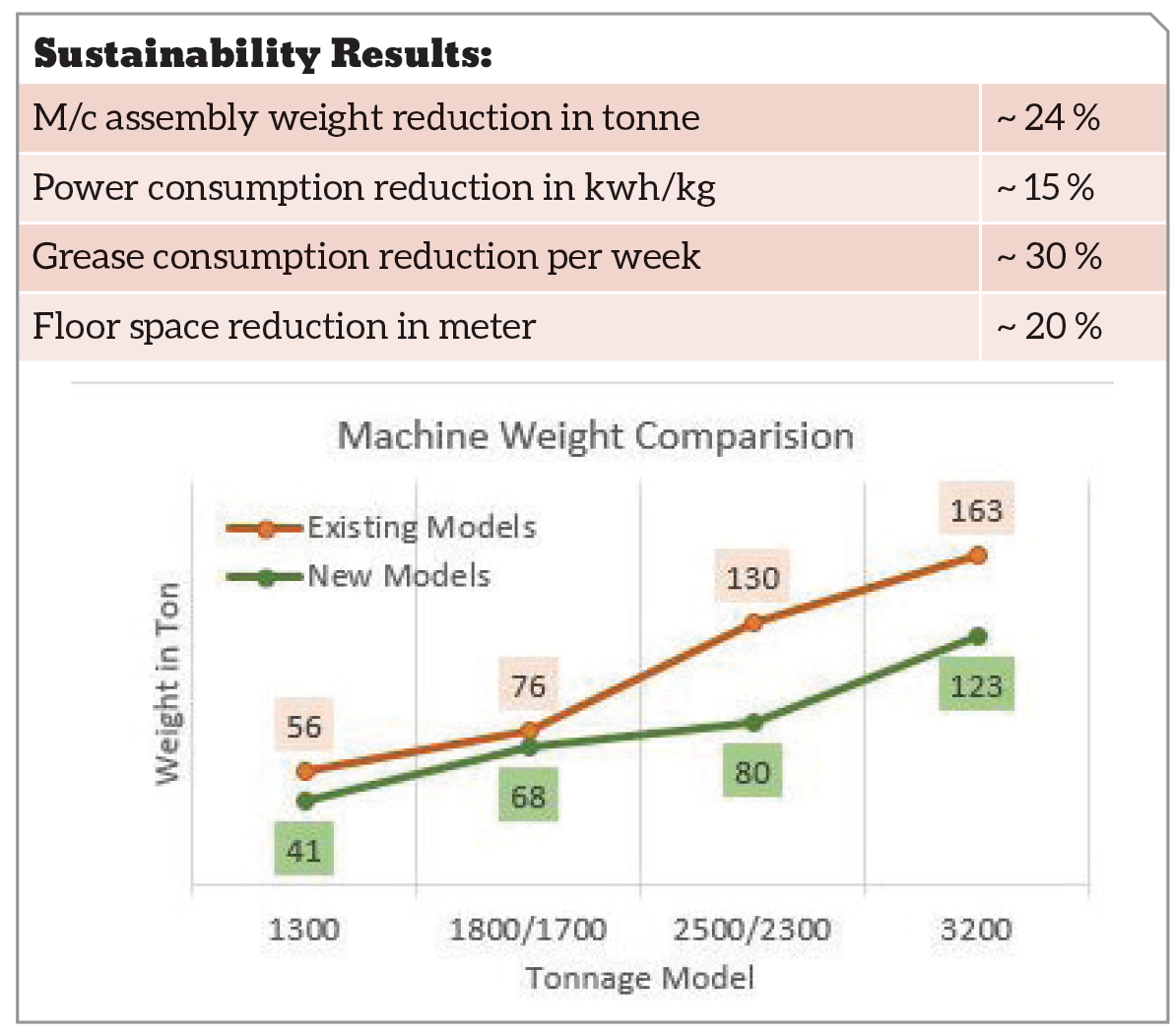

To reduce the weight of the clamp unit casting, we initially introduced a compact design. However, the weight reduction achieved was only an average of 10 percent in the first design, falling short of our target. In response, we conducted brainstorming sessions again and performed Finite Element Analysis (FEA) at an optimum level to identify further opportunities for cost reduction. The outcome exceeded our expectations with an impressive reduction of an average of 22 percent without compromising the machine’s performance and specifications.

Based on customer and market requirements, we developed best-in-class clamp force and Tie bar spacing against our competitors as per the below table.

After successfully achieving all our targets and thoroughly evaluating the design with FEA analysis, we moved on to our next crucial step: manufacturing the clamp unit based on our finalized design, installing it at our on-site location for a specific time, and validating it as per standards and customer requirements. During validation, we covered all real-world operating conditions and the anticipated loads and constraints in the defined application. The results were found satisfactory in all segments.

|

|

We faced several challenges during the implementation of this project:

- Achieving cost reduction with the same tonnage specifications and machine performance;

- Ensuring expertise in casting manufacturing and supplier competency;

- Establishing proficiency in the plating process on castings at the supplier’s end;

- Ensuring the quality performance of clamp castings is enhanced;

- Developing suppliers for casting machining of large-sized components;

- Single-piece machine loading through the existing crane facilities.

|

DEVESH DUDHWALA Deputy General Manager – Design |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe