SETTING THINGS IN MOTION

Nestled in the beautiful landscape of the Alps mountains, Fritz Studer AG organized its most-awaited Motion Meeting 2024 at its Steffisburg facility in Switzerland. This year’s edition marked the company’s journey of 111 years as well as celebrated the achievement of a successful 2023 fiscal year that exceeded the company’s sales targets.

Woven around the theme of ‘The Sound of Studer’, this year’s Motion Meeting was all about celebrating achievements. Taking pride in the company’s continued success, Jens Bleher, CEO, of Fritz Studer AG, noted that consistent investments in product development and site infrastructure have paid off. “We have turned our announcements into reality and used the time to improve our market position and strengthen ourselves for the future in the long term,” he shared.

Breaking records

According to Bleher, Studer could gain market share in many regions of the world. Amid a globally challenging investment environment, the company was successful in increasing its sales, especially in markets like the USA and China where the sales revenue peaked.

On an optimistic note, Bleher stated that the company’s new sales record in the Customer Care segment is highly encouraging and indicates a positive sign for the upcoming fiscal year. He said, “The order situation developed exceptionally well towards the end of the year.”

Sharing insights into the company’s recent record-breaking sales achievements, Sandro Bottazzo, Managing Director & CSO, Fritz Studer AG, remarked, “We achieved good results in many countries and even posted a new record order intake in some.” The orders for CNC universal cylindrical grinding machines were very solid. The machine with the highest volume was the S33, followed by the favorite, the S31, the S41, and the favorite. “When it comes to internal cylindrical grinding machines, it was the third-best year for incoming orders in the company’s history for the S131. Orders for the new S100 internal cylindrical grinding machine were also very pleasing and exceeded targets,” stressed Bottazzo.

|

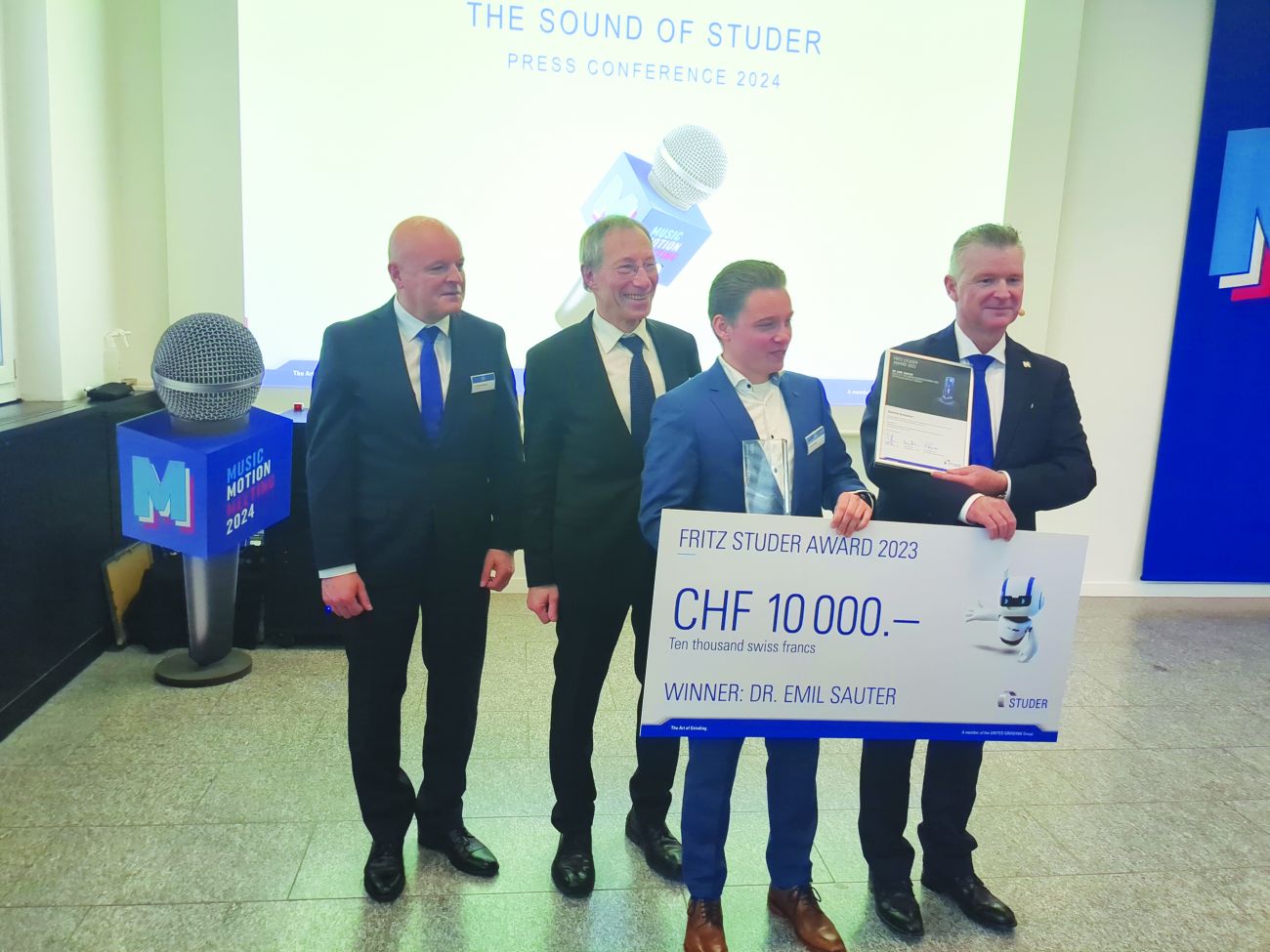

(2nd from L): Dr Emil Sauter from the Institute for Manufacturing Technology and Machine Tools at ETH Zürich bagged the Fritz Studer Award 2023 for Innovative Grinding Technologies. |

|

Studer witnessed successful sales of system machines and high-end products in India lately. The company is optimistic about the future prospects, anticipating continued growth in the Indian market throughout 2024. |

Crucial industry segments

Elaborating on the industry sectors in terms of order intake, he said that measured by customer segments, the Aerospace industry generated the largest increase in new orders and has now overtaken the Automotive industry. The largest individual segment is precision engineering, which is dominated by contract manufacturers. The Mechanical Engineering and Die & Mold segments also maintained their important positions in terms of orders. The company witnessed an increasing demand for precision cylindrical grinding machines in the Semiconductor industry as well.

Daniel Huber, CTO, Fritz Studer AG, remarked on the significant potential within the Semiconductor industry. “The demand for high-performance semiconductors is rising due to e-mobility and photovoltaics.”

Speaking on catering to the MSME and SME customers, Bottazzo mentioned the company’s grinding machines that are highly trusted by small- and medium-sized enterprises. “This segment remains strategically important for us,” he noted.

|

L-R: Prabhakar H, National Head - Sales & Business Development, Cylindrical Grinding Machines, United Grinding Group India; Pascale Keller, Sales Assistant, Fritz Studer AG; and Rolf Grossenbacher, Sales Director, Fritz Studer AG; at the rewards and recognition ceremony in Thun. |

Sustainability matters

Providing an outlook for the future, Huber shared, “The issue of sustainability continues to be important for us. The SmartJet® cooling system developed by Studer significantly reduces the need for coolant and energy in the grinding process, setting new industry standards.” He concluded, “In the long term, only the machine manufacturers who offer intelligent and efficient machines incorporating the latest technology can be successful.”

Meticulous operations

Elaborating on the focused operations strategy of the company, Stephan Stoll, COO, Fritz Studer, stressed, “The production-mix of the machines manufactured has shifted to more complex systems in 2023. Due to active procurement management and the normalization of global supply chains, orders were completed on time.”

“The implementation of the joint production strategy within the United Grinding Group, provided Studer with good utilization. Key operational projects included investments in automated manufacturing tools and state-of-the-art test stands. Studer is one of the few grinding machine manufacturers to produce its own high-quality spindles. The expertise for these strategically important machine components was specifically expanded. Comprehensive structural and logistical measures were further invested in Steffisburg and the internal grinding competence center in Biel for these prerequisites and further growth,” he further added.

Industry academia

Fritz Studer AG is well known for working closely with academia and encouraging young talents to make breakthrough R&D projects. In this edition of Motion Meeting, the Fritz Studer Award 2023 for Innovative Grinding Technologies was awarded to Dr Emil Sauter from the Institute for Manufacturing Technology and Machine Tools at ETH Zürich. The prize money was CHF10000. His topic was ‘Detection and avoidance of thermal damage for high-performance metal grinding processes using hybrid machine learning models’.

|

MURALI SUNDARAM Correspondent Magic Wand Media Inc murali.sundaram@magicwandmedia.in |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe