Collaboration is the Future

Human-robot collaboration enables the duo to work hand in hand with each contributing what they are best at. Together a formidable team, it promises manufacturing companies innumerable opportunities to be tapped.

Driven by the need for high accuracy, precision and performance of industrial processes, all industrial processing systems are turning to automation, making it an indispensable part of the manufacturing industry. Thus, a majority of companies today are looking for lean manufacturing solutions and the industrial manufacturing robots provide many benefits that companies require to stay competitive.

The speed, repeatability and efficiency that cobots provide can increase productivity, profits and reduce costs.

Increased adoption of automation

The application of robotics and automation has been successfully achieved in a wide range of industries dealing with well-defined processes and products including manufacturing, FMCG, automotive, healthcare, and pharmaceutical to name a few.

With this idea of higher production rate and the need for human interaction with machine automation, collaborative robots – or cobots – were first developed in 2008 by Universal Robots. Universal Robots are the leading manufacturers of advanced user-friendly and light industrial robotic arms from Denmark. Human-Robot Collaboration, or HRC, is the primary differentiator that sets these cobots apart from traditional robots. The idea is for humans and robots to work together towards a common goal, with each doing what they do best. While some tasks require human effort and thought, the accuracy, precision and mass production at higher efficiency is taken care of by the cobots. This latest technological advancement is in line with Industry 4.0, which is in sync with the automated revolution in the manufacturing industry.

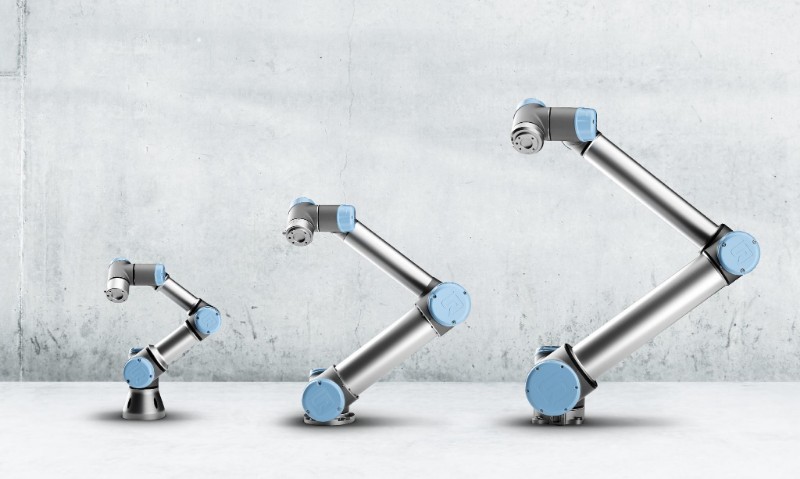

Three robotic arms from Universal Robots, namely the UR3, UR5 and UR10 (with respective payloads of 3, 5, and 10 kilograms) can be incorporated into various processes so that engineers can easily adapt the software to the specific needs of the required tasks. The easy programming, installation and collaborative nature of these robot arms allow them to work side by side with the workforce for efficient, high-quality products.

Cobots ideal for SMEs

For manufacturing companies, collaborative, light-weight robots are the new, economic alternative to expensive, traditional industrial robots. They make automation affordable and thus are a realistic choice, especially for small and medium-sized enterprises (SMEs). Cobots can help them compete more effectively, offering new opportunities for employees, and even improving worker safety. They are specifically designed to work along with the human workforce, without any costly, space-grabbing protective installations. Therefore, they are ideal for companies that produce a wide range of products and small lot sizes.

SMEs, at a global level are the backbone of developing economies, and play a dominant role in the Indian manufacturing industry. They are constantly in search of solutions for recession and unemployment. Governments are encouraging entrepreneurship at a great scale for providing multiple benefits including job opportunity creation, increasing the productivity, increasing industrial output and exports, development of entrepreneurship, development of rural economy, healthy competitiveness, gradually eradicating poverty and achieving various societal goals. When it comes to automation, SMEs face two major hurdles – initial capital investment and the availability of skilled manpower to handle automation and new technologies.

This approach is particularly appealing to the Indian manufacturing industry because labor-intensive conditions and collaborative robots together can help the Indian market achieve the best of both worlds by making precise use of this distinctive technology. Universal Robots is supportive of the ‘Make in India’ and ‘Digital India’ initiatives which endeavor to further boost manufacturing, employment and productivity along with the adoption of newer technologies, thereby bringing the Indian manufacturing industry to compete on a global platform.

Success stories

SMEW Textile Machinery Pvt Ltd, an MSME in Ahmedabad, collaborated with Universal Robots and deployed its first UR10 robotic arm in  January 2017. The cobot was used for a pick and place application. It was a new addition to the workforce but the simplicity and operator-friendly features of the cobots made the completion of tasks easier and faster. After the addition of the cobot to its manufacturing, SMEW realized that its production increased from 30 pieces to 80-90 pieces per week – i.e. a 300 percent boost in production over a period of just eight months.

January 2017. The cobot was used for a pick and place application. It was a new addition to the workforce but the simplicity and operator-friendly features of the cobots made the completion of tasks easier and faster. After the addition of the cobot to its manufacturing, SMEW realized that its production increased from 30 pieces to 80-90 pieces per week – i.e. a 300 percent boost in production over a period of just eight months.

For employees, on the other hand, cobots are the perfect tool to free them from monotonous and wearisome tasks. As a result, they can dedicate themselves to more creative jobs and work as productively as possible. Thanks to additional safety functions, it is possible for the cobot to work alongside its human co-workers either completely without any safety fencing, or with very minimal fencing. But cobots can do much more for their human colleagues than just alleviate them from repetitive and strenuous jobs; they can help create a new, more positive image for their profession by turningassembly-line workers into automation experts in only a few easy steps. Therefore, it is one of the most outstanding characteristics of cobot technology to create additional value for both the company and its employees.

Thus, the incorporation of collaborative robots will be a timely introduction to revolutionize the Indian industry, bringing the optimization of processes, reduction of waste, improvement in production, and higher efficiency and precision. The functions that have already embraced automation will continue to prevail with incremental improvements from the normal cycle of technological innovation.

Collaboration is powerful

Universal Robots has also taken a step forward from mass-customization to mass-personalization, which forms the base of Industry 5.0 – i.e. returning the human touch to manufacturing. Industry 5.0 products empower people to realize the basic human urge to express themselves, and cobots are exactly the tools manufacturers need to produce these personalized products according to their consumers’ demands.

By putting human beings back at the center of industrial production – aided by tools such as cobots – Industry 5.0 not only gives consumers the products they want today, but gives workers jobs that are meaningful and take a step ahead in manufacturing.

For manufacturing companies, collaborative, light-weight robots are the new, economic alternative to expensive, traditional industrial robots.

.png) Pradeep David

Pradeep David

General Manager

South Asia Universal Robots

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe