HYBRID MANUFACTURING The Next Industrial Revolution

Hybrid manufacturing represents the perfect union between established machining expertise and cutting-edge additive technology, enabling components previously deemed impossible to manufacture. Here’s an insight into the emerging technology poised to revolutionize production across multiple sectors…

In an industrial landscape where competition grows fiercer by the day, Indian manufacturers face increasing pressure to reduce costs while simultaneously enhancing quality and managing complexity. The answer may lie in an emerging technology that combines the precision of traditional machining with the transformative capabilities of additive manufacturing.

The Power of Combination: Understanding Hybrid Manufacturing

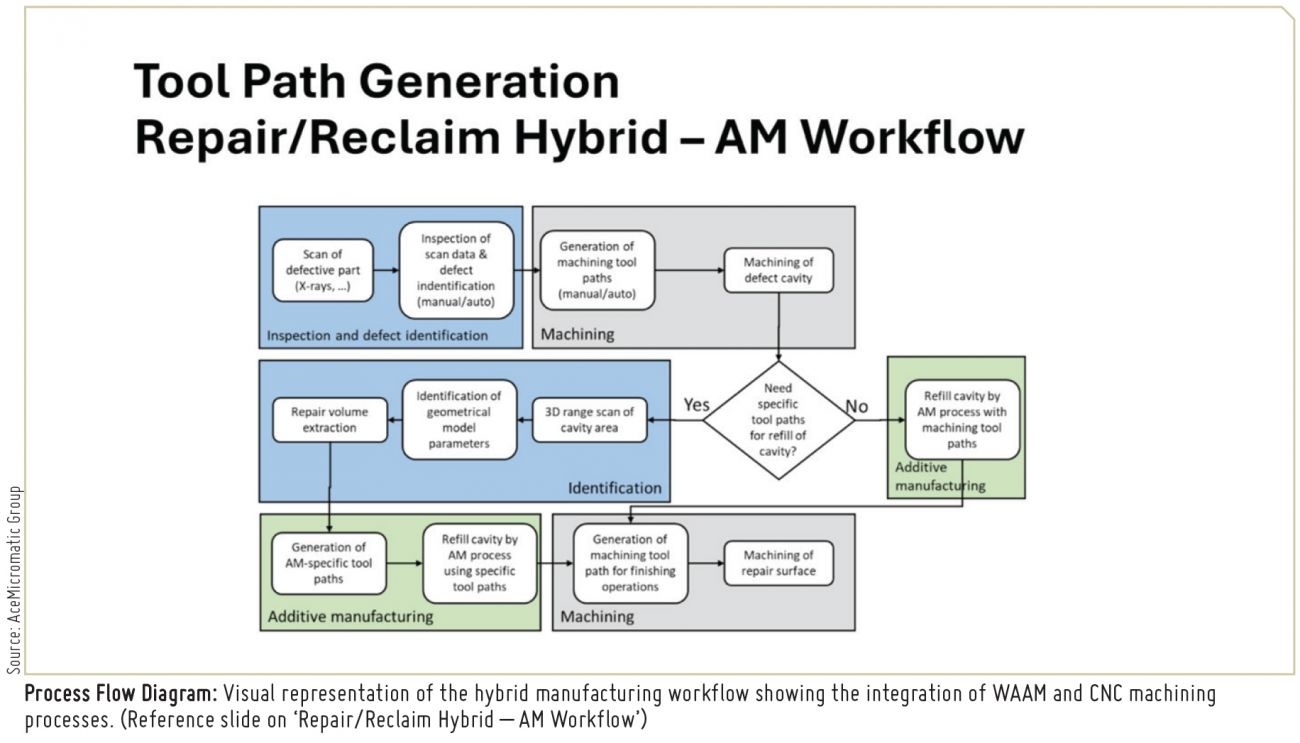

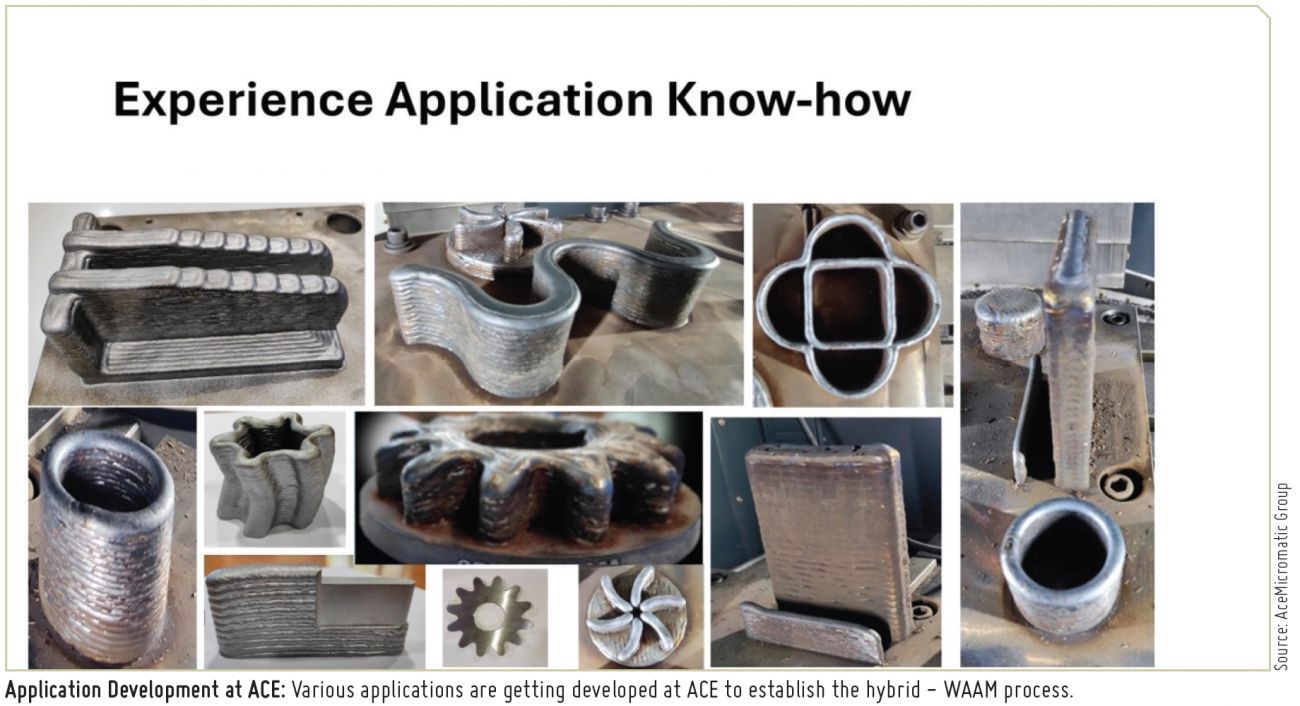

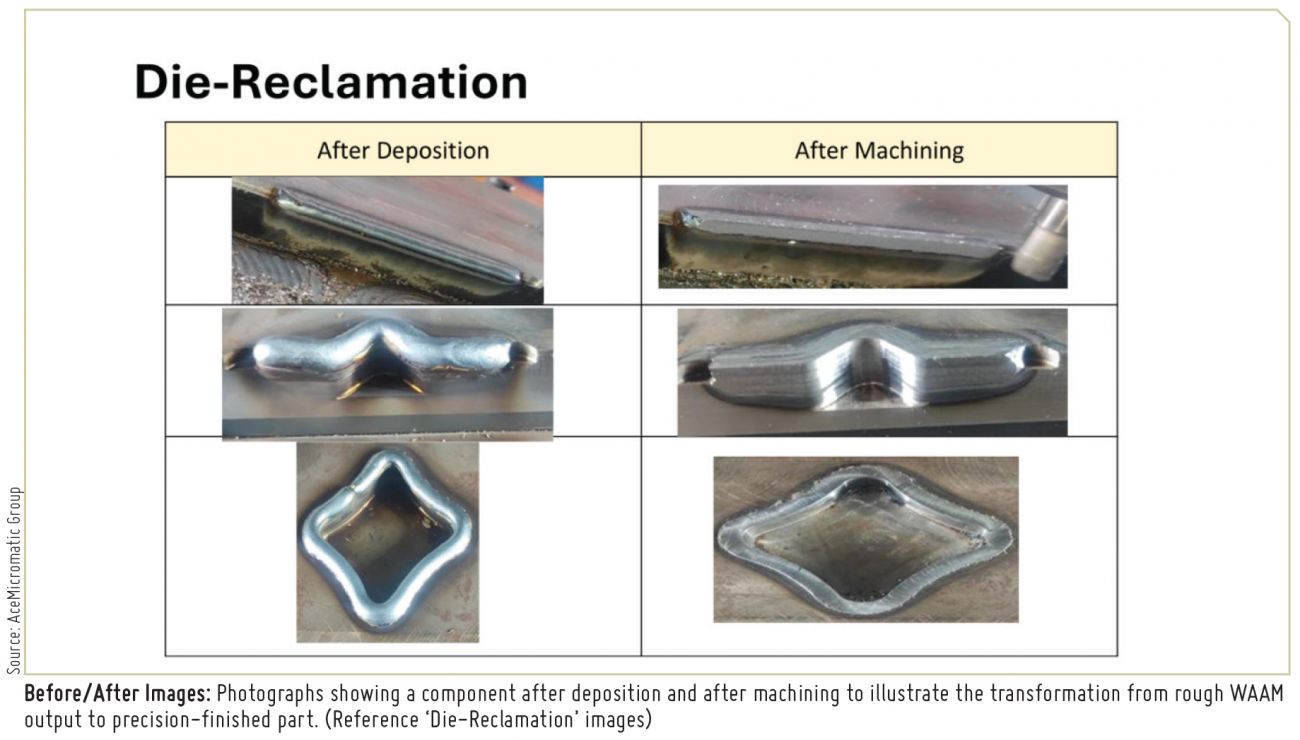

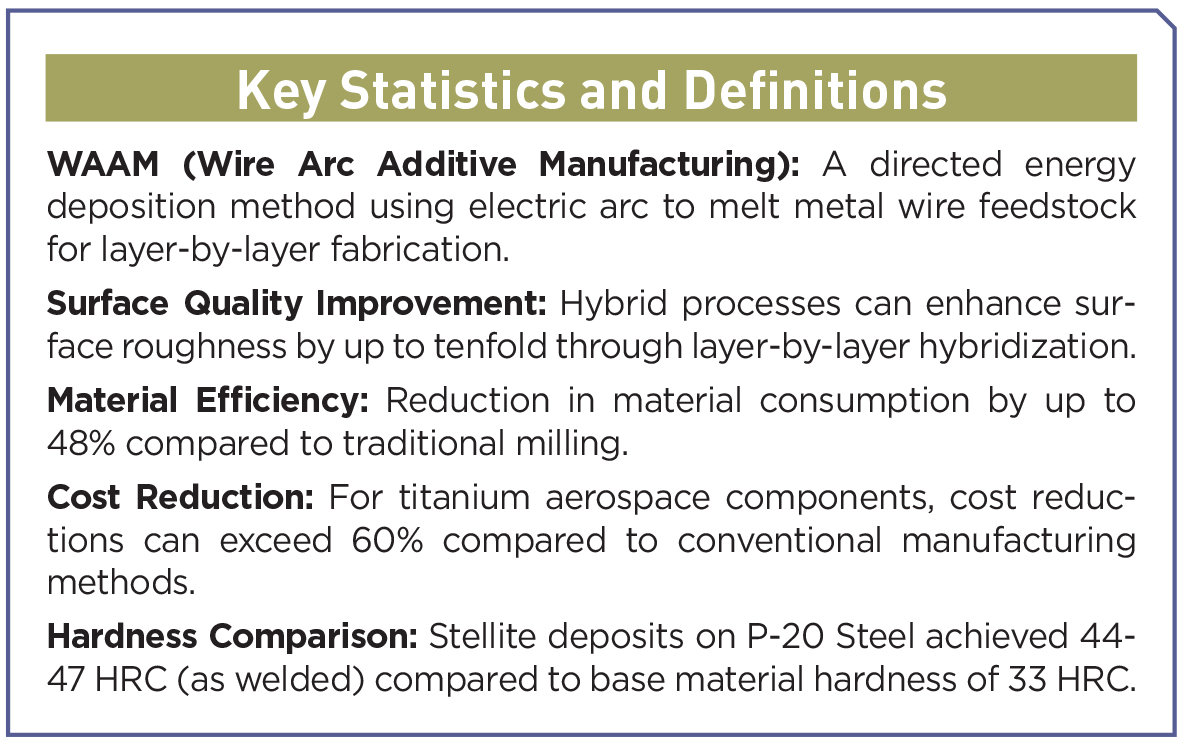

At its core, hybrid manufacturing integrates additive manufacturing processes, specifically Wire Arc Additive Manufacturing (WAAM), with traditional CNC machining. This integration creates a manufacturing ecosystem where metal components can be built layer by layer through controlled welding processes and then precision-finished using conventional machining techniques.

The approach leverages the best of both worlds: additive manufacturing's ability to create complex geometries with minimal material waste, combined with the dimensional accuracy and superior surface finish that only traditional machining can provide. The result is a manufacturing process particularly suited for high-value, complex components in industries ranging from Aerospace to Die & Mold production.

For Indian manufacturers already equipped with CNC machines, the transition to hybrid manufacturing can be remarkably straightforward. The typical setup involves integrating a welding system, complete with power source and wire feeder, onto an existing 3+ axis CNC machine. This relatively modest investment can dramatically expand production capabilities.

Economic Benefits:

The Numbers Behind

the Revolution

Start Small: The Bootstrap WAAM Approach

Unlike laser-based metal printers costing crores of rupees, WAAM can use existing welding gear. A bootstrap setup might include:

- A second-hand 6-axis industrial robot

- A standard MIG/MAG or TIG welder

- Simple integration and programming.

This can be done in the range of INR 6–9 lakh, making it feasible for startups or MSMEs to begin exploring hybrid manufacturing with minimal risk. With low-cost wire feedstock and high deposition rates, WAAM makes large part production faster and cheaper.

AceMicromatic’s model aligns with this approach, supporting businesses to start small and scale up.

| Necessity is the mother of innovation. The current limitations of WAAM are paving the path for groundbreaking advances in hybrid manufacturing. |

Compelling argument for hybrid manufacturing

The economic argument for hybrid manufacturing becomes particularly compelling when working with expensive materials. While the cost-benefit analysis may be less dramatic with common structural steels (approximately INR 200/kg), the savings become significant with specialty materials.

For example, in aerospace applications using titanium alloys like Ti-6Al-4V (approximately INR 8,000/kg), studies demonstrate cost reductions exceeding 60 percent compared to traditional manufacturing methods. This saving stems primarily from dramatic reductions in material waste, hybrid methods can decrease material consumption by up to 48 percent compared to conventional milling.

For small and medium enterprises (SMEs) in India's Manufacturing sector, hybrid manufacturing offers another critical advantage: the ability to produce small-batch, high-complexity components economically. Rather than relying on expensive casting processes for limited production runs, manufacturers can produce components with equivalent or superior mechanical characteristics in less time and at lower cost.

Technical Innovations: Overcoming Hybrid Manufacturing Challenges

Despite its promise, hybrid manufacturing faces several technical challenges that Indian manufacturers must address to maximize benefits. The most significant of these include poor surface finish, dimensional inaccuracy, residual stresses, and thermal management issues.

Recent research conducted at the Indian Institute of Technology, Guwahati has made significant progress in addressing these limitations. Advanced cooling techniques have demonstrated particular promise, with in-situ cooling systems showing temperature reductions of up to 59 percent during the manufacturing process. This cooling not only improves dimensional stability but also enhances material properties.

Process optimization represents another frontier of innovation. Advanced welding techniques like Pulse MIG welding (GMAW-P) and Cold Metal Transfer Advance Technology (CMT) have dramatically reduced heat input during deposition, in some cases by as much as 90 percent compared to conventional MIG/MAG processes. This reduction minimizes thermal distortion while improving weld quality and reducing spatter.

Necessity is the mother of innovation. The current limitations of WAAM are paving the path for groundbreaking advances in hybrid manufacturing.

| Despite its promise, hybrid manufacturing faces several technical challenges, including poor surface finish, dimensional in accuracy, residual stresses, and thermal management issues. |

Real-World Applications: From Impellers to Rocket Engines

The versatility of hybrid manufacturing is perhaps best illustrated through its diverse applications. In the Power Generation sector, WAAM technology has revolutionized impeller reconditioning and manufacturing. Rather than machining entire impellers from solid cylindrical workpieces, a process that generates excessive waste, manufacturers can now build up the complex geometry through additive processes and then finish-machine only where necessary.

Even more dramatically, aerospace applications have demonstrated the technology's transformative potential. NASA has successfully employed 3D printing techniques to produce rocket engine components for its Artemis exploration mission. According to NASA officials, “This technology advancement is significant as it allows us to produce the most difficult and expensive rocket engine parts for a lower price tag than in the past.”

In India's growing Medical Device Manufacturing sector, hybrid manufacturing enables the production of customized implants and surgical tools with complex internal structures that would be impossible to create through traditional manufacturing methods alone.

The Path Forward: Emerging Trends and Opportunities

For Indian machine tool manufacturers and users looking to capitalize on this technology, several emerging trends deserve attention. Advanced process monitoring and control systems are increasingly incorporating machine learning algorithms to optimize deposition parameters in real time. Multi-material manufacturing capabilities are expanding, allowing for gradient materials with varying properties within a single component.

Perhaps most significantly for India's manufacturing ecosystem, standardization and certification processes are evolving rapidly. As these standards become established, they will provide the regulatory framework necessary for wider adoption of hybrid manufacturing in critical applications.

The integration of specialized CAD/CAM software represents another crucial development area. Current software solutions often treat additive and subtractive processes separately, creating workflow inefficiencies. The development of integrated solutions specifically designed for hybrid manufacturing workflows presents a significant opportunity for software developers serving India’s Manufacturing sector.

| As global manufacturing trends increasingly favor high-mix, low-volume production with greater complexity, hybrid manufacturing positions Indian manufacturers to compete effectively in high-value market segments. |

Conclusion: Positioning for the Future

As global manufacturing trends increasingly favor high-mix, low-volume production with greater complexity, hybrid manufacturing positions Indian manufacturers to compete effectively in high-value market segments. By addressing current limitations through continued innovation in process control, thermal management, and integrated software solutions, India’s Manufacturing sector can leverage this technology to reduce costs, minimize material waste, and expand production capabilities.

For forward-thinking machine tool manufacturers and users, the message is clear: hybrid manufacturing represents not merely an incremental improvement but a fundamental shift in production capabilities, one that merges the precision of India's established machining expertise with the limitless potential of additive manufacturing.

|

Sumit Y Waghmare |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe