THE SHOW WHERE GRIT DROVE GEAR

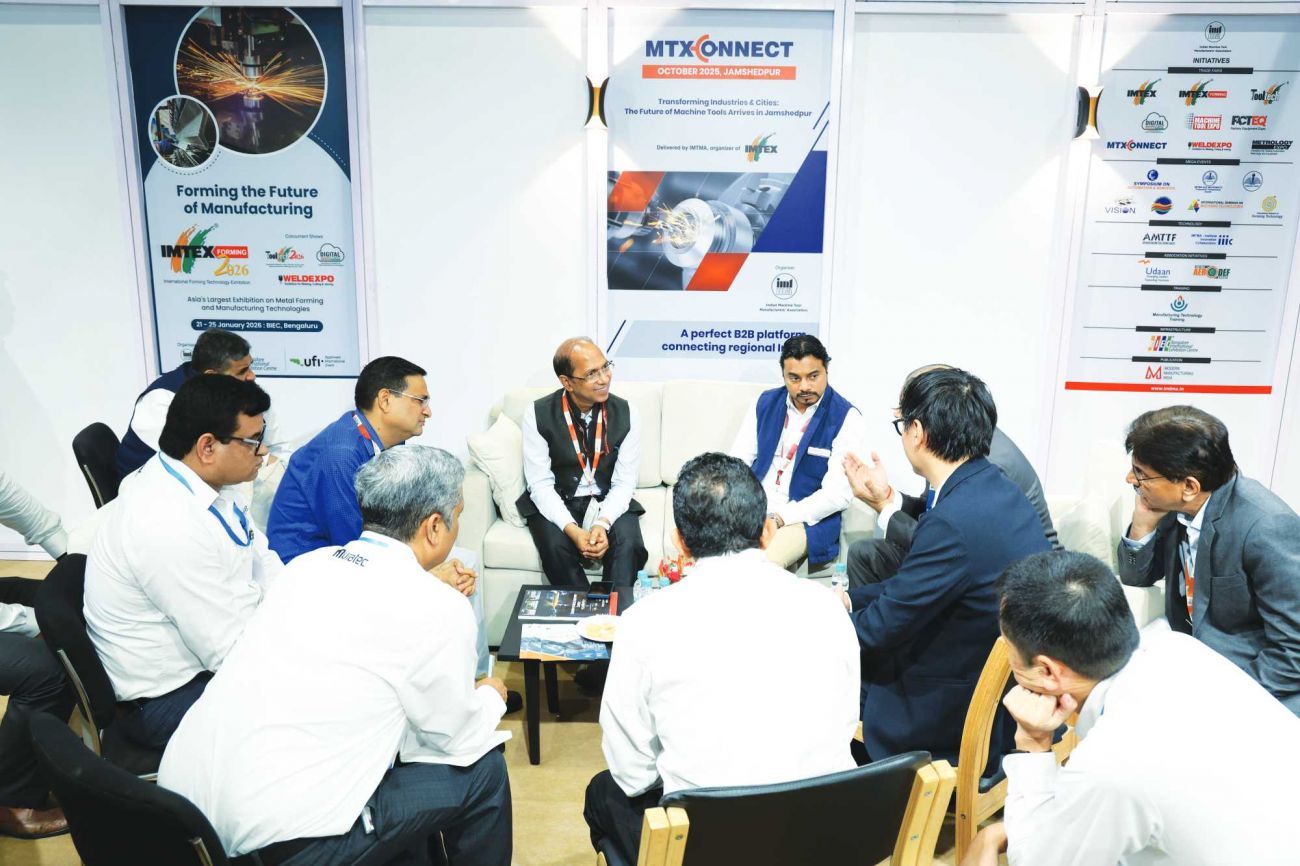

The fifth edition of Delhi Machine Tool Expo (DMTX), co-located with the second edition of Factory Equipment Expo (FACTEQ), from May 9-12 at Bharat Mandapam, Pragati Maidan, New Delhi, was a remarkable display of India’s industrial grit. Organized by the Indian Machine Tool Manufacturers’ Association (IMTMA), the event successfully brought together advanced technologies, business networking opportunities, and industry insights, despite challenges related to global uncertainties and logistics.

In his welcome address at the inauguration of DMTX 2025, Rajendra S Rajamane, President, IMTMA, acknowledged the swift turnaround behind the event, stating, “We’re thrilled to have successfully organized the show in just 48 hours,”—a testament to the commendable efforts of IMTMA and its partners in delivering a seamless experience.

He went on to emphasize the strategic role of the Machine Tool industry, noting, “The Machine tool industry is the key to manufacturing growth, and supports significant research in varied sectors.” Highlighting India’s accelerated momentum—driven largely by metal cutting, which constitutes 75 percent of the growth driven by industry demands from Electronics, Semiconductors, and Automotive sectors, Rajamane shared, “In terms of global positioning, the Machine Tool industry in India ranks 9th in production and 6th in consumption, as per 2023 Gardner Intelligence report.”

Adding to this, Jibak Dasgupta, Director General & CEO, IMTMA, highlighted the industry’s growth trajectory, saying, “Our data-backed reports indicate the industry’s forward movement in production and consumption in both metal forming and metal cutting.”

He also emphasized the importance of global outreach and export strategy, noting, “We’ve created a special export-focused group. When we attend global trade shows, we analyze and monitor gaps and plan interventions. We aim to grow India’s Machine Tool industry’s presence not just domestically but also globally.”

Vijay Mittal, Joint Secretary, Ministry of Heavy Industries (MHI), Government of India (GoI), graced the opening ceremony as the ‘Chief Guest’, and Premjit Lal, Executive Director, India Trade Promotion Organisation (ITPO), as the ‘Guest of Honor’.

| DMTX 2025, co-located with FACTEQ 2025, featured over 250 exhibitors from 10 countries, presenting cutting-edge manufacturing technology, including standout innovations like LMW’s JD2 L – compact machining center, BFW’s Prima 55 Pro HMC, and AceMicromatic Group’s advanced machining centers. |

Underscoring the significance of such platforms in boosting domestic innovation, Lal said, “This is a great occasion where manufacturers from different industries have gathered together for a four-day event. They will be focusing on the technological and innovative progress of Indian products on display.”

|

|

|

Echoing similar sentiments and highlighting India’s transformation, Mittal shared, “The Indian Machine Tool industry’s size was roughly INR 7,500 crore in 2014, and we’ve reached nearly INR 27,000 crore by 2023-24. This is an indication that there has been a growth of around 3.5X over a decade. We must now focus on achieving trade balance through indigenous excellence.”

| DMTX 2025 was organized and executed within just 48 hours, reflecting IMTMA’s operational agility and the collective resilience of the Indian machine tool industry amid logistical and geopolitical challenges. |

Spotlight on Exhibitor Excellence

With over 250 exhibitors from 10 countries, DMTX 2025 offered a wealth of next-gen manufacturing technology. AceMicromatic Group showcased a formidable lineup, attracting attendees from the Automotive, Aerospace, and Medical sectors. “Our booth was designed as a complete solutions ecosystem,” shared Amit Goel, Assistant General Manager, Marketing & Service Division, Ace Designers Ltd, endorsing the Group’s complete portfolio coupled with IIoT solutions. “We got a total of 249 leads and 23 orders worth INR 4.25 crore,” he revealed. “Our Turn Mill Center/Polygon Turning and compact DTC-350XL was the point of attraction. Our simulator also garnered significant interest from ministry delegates and educational institutes.”

LMW's booth attracted an engaged flow of visitors, leading to a noteworthy generation of potential leads. “The expo served as an effective platform for networking with industry professionals and decision-makers, facilitating meaningful business discussions. The diverse visitor base, including representatives from various industry sectors, contributed to the dynamic atmosphere at our booth,” shared Manoj Kumar, Regional Head – Delhi, LMW Ltd.

The company showcased a range of advanced CNC machines, which garnered considerable attention. “Our S Turn 2M – Compact Turnmill Center, LTV 30 Plus – Vertical Turning Center, JD2 L – Compact Machining Center, and J2 R – Vertical Machining Center with RAPC. These models were appreciated by visitors and customers for their precision, speed, and suitability for various industrial applications, he informed.

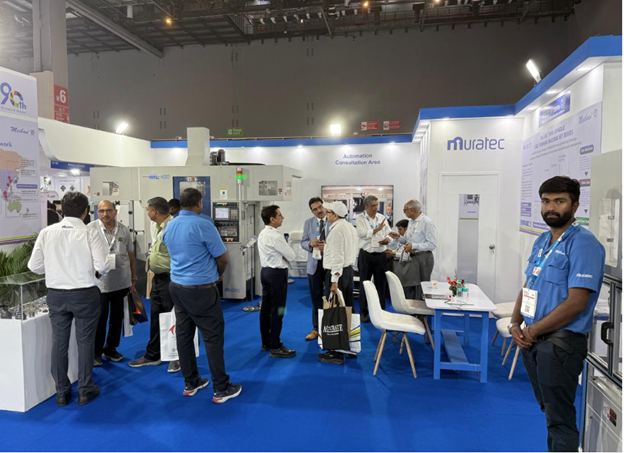

Meiban Engineering Technologies Pvt Ltd, an associate company of Muratec, Murata Machinery, Ltd, Japan, received visitors from the North Indian Automobile industry, including Tier 1, 2, 3, and 4 visitors, as well as customers from the replacement part market. “With many of our known as well as new customers visiting our booth, this was the platform where all the prospects could reach us and we could demonstrate our technologies to them,” said Rishi Kapoor, Associate Vice-President & Country Head, Meiban Engineering Technologies. “We received around 8 to 10 new enquiries, many of which show strong potential to convert into business. Our ML400 Shaft Turning Machine with Twin Turret drew the most attention and was highly appreciated by customers—particularly for its performance.”

| With outcomes of strong business and lead generation, leading companies like AceMicromatic, Jyoti CNC, UCAM, Meiban Engineering, and more reported high-quality visitors, hundreds of leads, and multiple confirmed orders, validating DMTX as a serious business platform. |

Market Voices

“Despite the current geopolitical tensions impacting overall turnout, DMTX 2025 was a well-organized event with a strong quality of visitors,” noted Vijay Zaritaklikar, National Sales Manager, UCAM Pvt Ltd.

|

|

“There was a strong interest in our high-precision rotary tables, especially the 4th axis models, which drew attention from automation-driven manufacturers,” he shared. “Most of our interactions were with players from the Automotive sector, followed by those from General Engineering and Agricultural Machinery industries.”

Offering a clear market perspective and engaging with serious buyers across industries seeking productivity-driven solutions, Vikas Soni, Regional Manager – Sales at Jyoti CNC Automation Ltd, shared, “We saw a healthy mix of visitors—from decision-makers at large OEMs to MSME business owners—reflecting strong interest across segments. In terms of lead generation, we recorded a significant number of qualified inquiries, especially from the NCR and nearby regions.”

| Underscoring strong policy collaboration and export focus, IMTMA has formed a special export group to close global capability gaps and align Indian production with international demands—aiming to grow India’s machine tool presence not just domestically but globally. |

Among the machines that drew the most attention for Jyoti CNC Automation were CNC Turning Centers with Automation, Vertical Machining Centers (VMCs), and advanced 5-Axis and Multitasking Machines, which are particularly popular with Tier-1 and export-oriented manufacturers aiming to reduce setups and enhance precision.

Sachin Sinha, Founder & Director, Tecroot Space OPC (P) Ltd, presented a visitor’s perspective, “DMTX 2025 is a clear indication that the Manufacturing industry shows all the signs of moving rapidly towards smart factories to redefine the 21st-century industrial revolution.”

“Starting from CNC machine tools and cutting tools to peripheral systems like oil filtration units, mist filtration units, high-pressure systems, tool setters, etc., all the solution providers are integrating IoT systems into their products,” he remarked. “And that perfectly matches with what the component manufacturers are looking for to make their factories future-proof and ready to serve customers globally.”

Highlighting key showcases that stood out, he shared, “SF Hawk demonstrated its smart manufacturing capabilities through the VAJRA solution, which supports CNC machine users with OEE (Overall Equipment Effectiveness) and traceability. SRB Machines showcased its ‘Made in India’ CNC grinding machines, while AceMicromatic Group highlighted its advanced machining technologies with a strong emphasis on Factories of the Future and engineering excellence.”

Validating Indian Engineering

An enriching interaction was held around the Omnibus Technical Regulations (OTR) and the upcoming Capital Goods Policy, where Mittal urged, “If we’re able to create some niche in fields such as electronic machine manufacturing, advanced chemistry, and cell manufacturing technologies, we can bring a better trade balance in the near future.”

|

|

Echoing the importance of aligning with national policies, Dasgupta opined, “All the major economies in the world are coming here and setting up their plants. As Indian machine tool builders, we must equip ourselves to meet international standards. Our current domestic market share hovers around 45-50 percent, which we need to increase by upgrading capabilities and ensuring we meet global standards. Hence, the joint collaboration and the partnership that we have with the MHI and other ministries in the Government of India are highly crucial going forward.”

Rajamane echoed this view, “IMTMA and MHI have been collaborating on several fronts. We’d like to thank MHI for continuing to support this industry with various schemes and initiatives.”

Stressing the need for R&D coupled with India-first thinking and identifying global gaps, he added, “Our collaboration with Advanced Manufacturing Technology Development Centre (AMTDC) in IIT Madras has propelled a technological advancement in the Machine industry.”

Speaking about the association, the IMTMA President remarked, “IMTMA, as the apex body for the Machine Tool industry in India, plays a vital role in its growth and development. The association actively engages in policy advocacy, organizes trade fairs, promotes exports, and drives technology missions. Skills are another criterion that is critical in today’s manufacturing, for which we have a dedicated skill upgrading center.”

| At DMTX, a very clear shift toward IoT-enabled machines, automation, and smart factory systems was observed, with exhibitors and visitors aligning around Industry 4.0, digital transformation, and next-generation manufacturing technologies. |

Platform with a Purpose

|

|

Co-located with the second edition of FACTEQ, the fifth edition of DMTX brought the latest technologies to the doorstep of Northern India’s industrial ecosystem. Through key displays, strategic dialogues, and dealer-developer discussions, the event captured the essence of India’s manufacturing ambition and furthered the vision of ‘Atmanirbhar Bharat’.

Co-located with the second edition of FACTEQ, the fifth edition of DMTX brought the latest technologies to the doorstep of Northern India’s industrial ecosystem. Through key displays, strategic dialogues, and dealer-developer discussions, the event captured the essence of India’s manufacturing ambition and furthered the vision of ‘Atmanirbhar Bharat’.

Moving forward with clarity and purpose, stakeholders are building on their experience to gear up for an even more impactful edition. As the Joint Secretary of the Ministry of Heavy Industries aptly noted, “The real contribution is not only what we manufacture as a machine, but the multiple times of growth of the products manufactured out of those machines.” This multiplier effect—driven by innovation, policy collaboration, and indigenous excellence—is precisely what DMTX seeks to accelerate.

|

Sovan Tudu |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe