Mowito’s AI-Driven Robotic Automation Solutionsy

Mowito builds advanced physical AI models that learn directly from human demonstrations and control robot arms using real-time vision and tactile feedback. Mowito’s AI models enable complex, high-precision assembly tasks—handling rigid and flexible parts, even while in motion—without relying on CAD models or fixturing.

Neural Pick-Torque - Adaptive fastening solution

Neural Pick-Torque is an AI-powered, vision and force-guided robotic fastening solution that tracks and aligns to fasteners’ positions in real time—even on moving conveyors. Operating without CAD models or fixtures, it adapts on the fly to part variation, delivering precise, reliable fastening at line speed.

Neural-Inspect

Neural Inspect is an AI-powered robotic inspection system that tests parts the way they are meant to work. While traditional inspection systems rely only on vision checks, Neural Inspect uses robot arms with integrated vision and force sensors to physically interact with every critical touchpoint—capturing tactile information to uncover hidden functional defects with higher confidence.

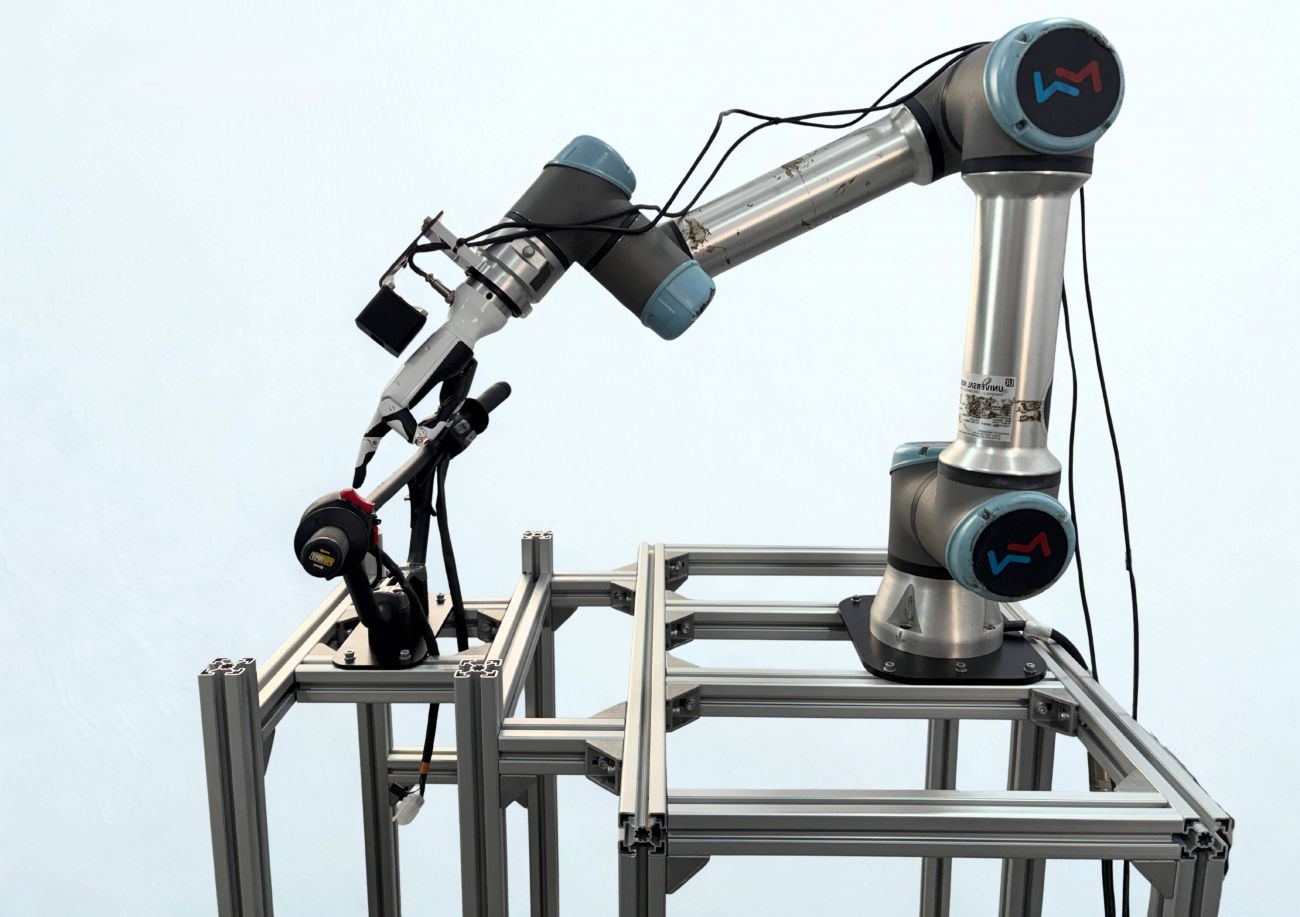

WireMax-Pro

WireMax-Pro is Mowito’s dual-cobot platform for automating complex wire-harness manufacturing. Designed to handle multiple process steps—from wire routing and securing to inspection—it brings speed, consistency, and scalability to harness assembly. At IMTEX 2026, WireMax-Pro showcases its inspection module, automatically laying the harness on a board and verifying wire lengths and connector integrity with complete, blind-spot-free inspection. Additional modules for taping and clamping are currently in development.

WireMax-Insert

Mowito’s WireMax-Insert is a robotic cell designed for ultra-fast and highly accurate dummy insertions. The system is easy to reconfigure, requiring minimal changes to switch between different dummy types and connectors—making it ideal for high-mix, high-throughput production environments.

Mowito

www.mowito.ai

Hall & Stall: 4/C-150

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe