NORD DRIVESYSTEMS’ Intelligent Drives Improve Availability

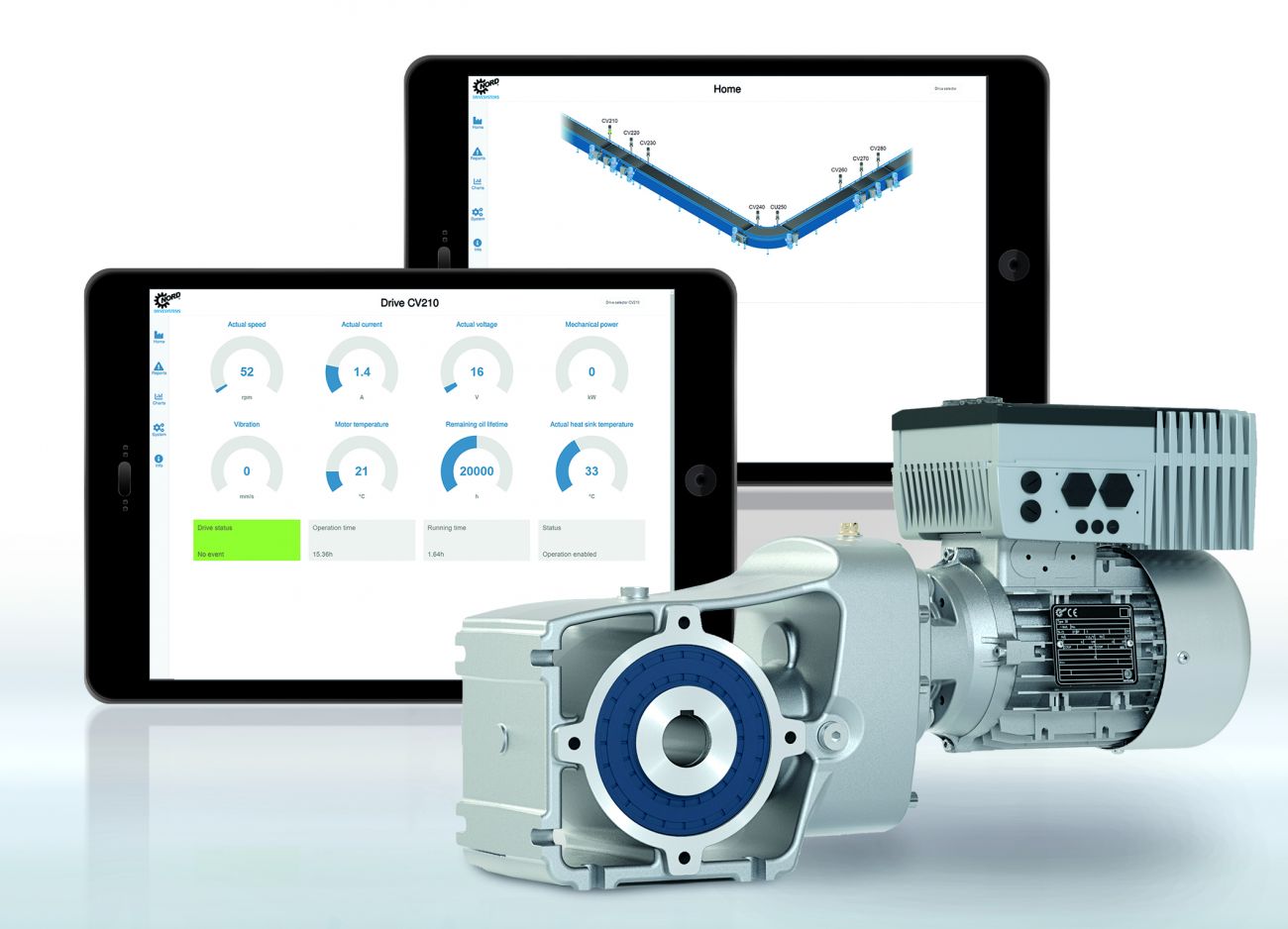

Bargteheide, Germany – NORD DRIVESYSTEMS’ intelligent PLC drive technology evaluates analogue and digital data quickly, efficiently, and comprehensively, laying the groundwork for condition monitoring and predictive maintenance, while also increasing availability.

Predictive maintenance is the systematic continuation of condition maintenance with the goal of proactively maintaining machinery and equipment and detecting changes, reducing downtimes, and improving overall plant efficiency. The traditional time-based maintenance is being replaced by status-oriented maintenance. Condition monitoring enhances the triad of gear unit, electric motor, and frequency inverter with improved safety and reliability, particularly in demanding production environments where industrial gear unit installations are typically used in sensitive applications and their failure can cause severe damage, such as intralogistics, the food industry, or the heavy-duty sector.

This is where condition monitoring for preventative maintenance comes in: The networked drive units can collect their condition data in the inverter’s own PLC and pre-process it with data from connected sensors and actuators using intelligent algorithms and software in an IIoT environment. Optionally, the result of the pre-processing or the entire data set can be sent to an edge device. Data of all subsystems is managed and evaluated there. It’s then available as pre-selected and edited smart data for further use and visualization.

Conducting data analysis

The sensorless determination of the optimum oil change time based on oil temperature is an example of a real-world application. This is due to the fact that oil temperature is a significant factor in gear unit oil aging. This information, when combined with available gear unit parameters and specific operational parameters, allows the oil change time to be calculated precisely. It is not necessary to use a physical temperature sensor. The drive data is pre-processed in the integrated PLC of the NORD frequency inverter, which is also used as an evaluation unit. The calculated data is accessible to the customer via all common interfaces.

The right PLC software architecture

Optionally, the drive equipment can be extended and adjusted to the specific automation task. Customers can choose which tasks (drive monitoring, drive control, and process control) they want to directly shift into the drive. This scalability allows smaller production areas to gain firsthand experience before reorganizing the plant. There are three different configuration levels to choose from. The drive unit PLC only performs drive monitoring at the first level. The PLC pre-processes the drive parameters before communicating them to the higher-level control system in charge of drive and process control. The PLC integrates the drive control and also runs drive-related functions at the medium level. The inverter PLC completely replaces the higher-level control system at the higher configuration level. A local data management without an internet connection can optionally apply the data in addition to communication to a control unit.

Image Source: NORD DRIVESYSTEMS

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe