TRUMPF Presents VCSEL Heating Systems for Faster Microchip Assembly

Ulm, Germany – TRUMPF Photonic Components introduces new processes for flip-chip assemblies in the electronics industry that use their VCSEL heating systems. Cycle times for Laser Assisted Bonding (LAB) and Laser Assisted Soldering (LAS) using VCSEL heating systems are reduced down to a ninth compared to standard reflow soldering processes. Furthermore, because VCSEL heating systems work with high precision, the quality and reliability of PCB assemblies is improving. The heat is only applied to the PCB and semiconductor die where it is needed, as the intensity distribution of laser radiation can be adjusted by individual control of single laser zones. As a result, this technology improves the quality and lifetime of PCB boards, as well as die attach and solder interfaces, by reducing warpage and heat within the die.

The assembly process also benefits from very repeatable and accurate die bonding and soldering conditions, as the VCSEL heating system enables homogeneous illumination, fast switching times, and precise power control. The overall footprint for microchip assembly is another consideration. It can be reduced when compared to conventional reflow solutions because the VCSEL heating systems are very compact.

|

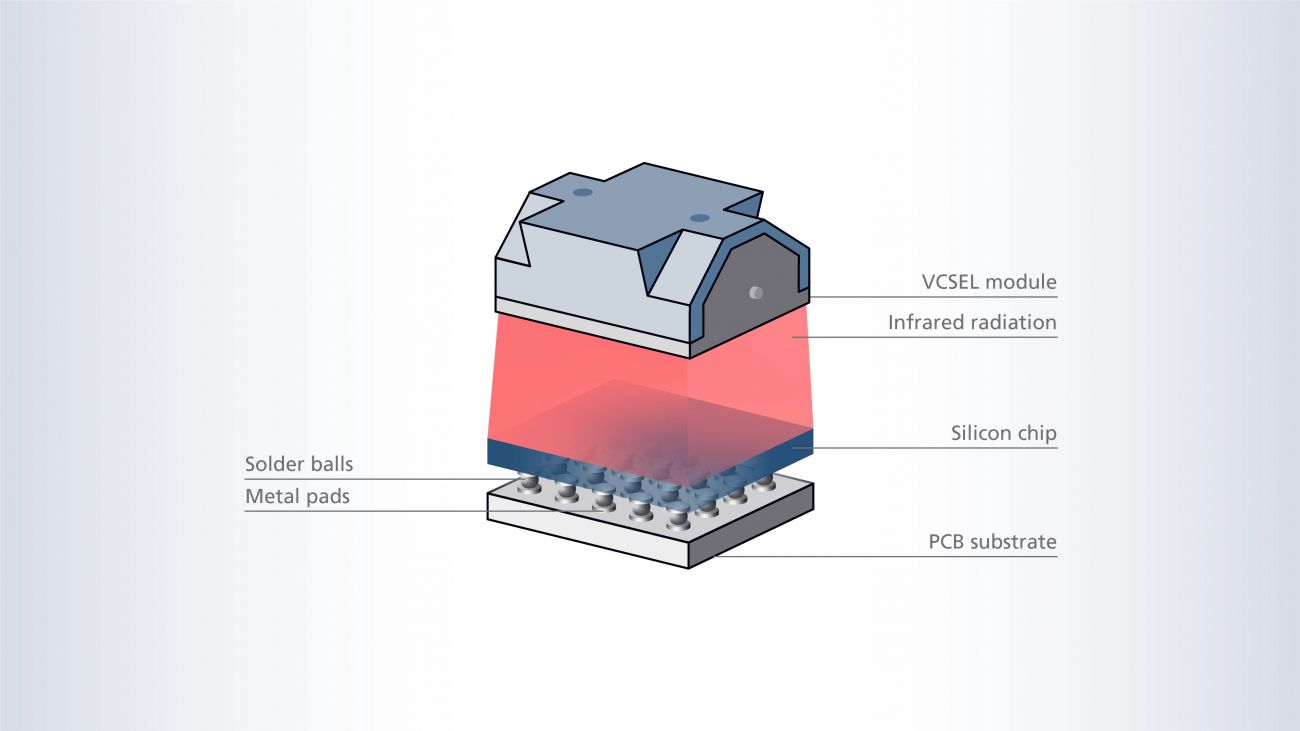

Laser-Assisted-Bonding (LAB) - Schematic drawing of the LAB process. A flip-chip is attached to a PCB board by laser energy transmitted through a silicon die to melt the solder balls between chip and PCB. |

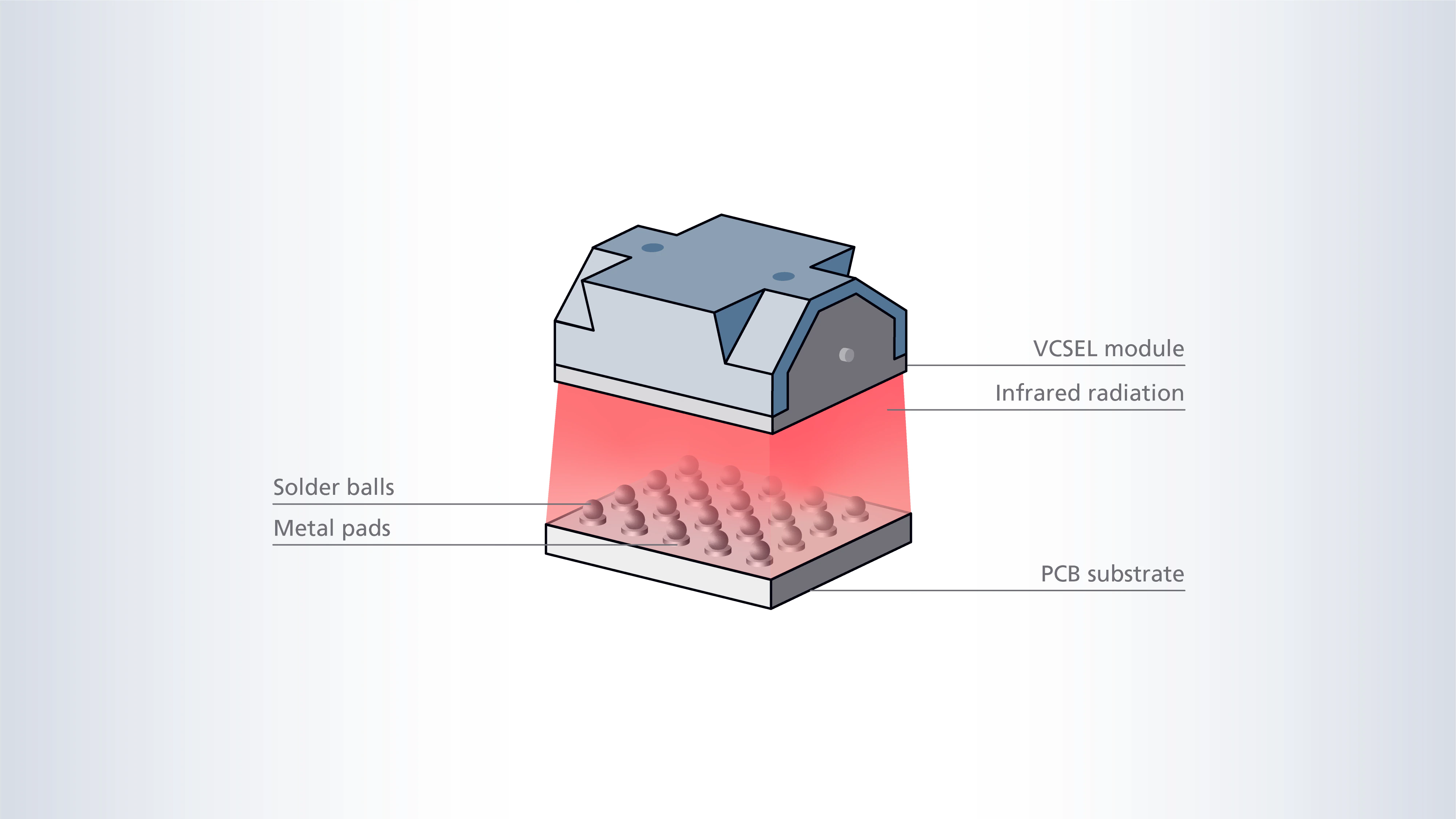

Laser Assisted Soldering (LAS) - Schematic drawing of the LAS process. A flip-chip is attached to a PCB board by laser energy directly melting the solder balls to the PCB. |

When solder balls are soldered directly onto the PCB using VCSEL infrared heat treatment, the process is known as Laser Assisted Soldering (LAS). This is especially important in order to support the trend toward smaller solder balls and pitches, which reduces the amount of overall building space required in consumer electronics. A flip-chip is placed on a PCB board using solder balls as a connection during the Laser Assisted Bonding (LAB) process. The VCSEL system heats the chip from above and transmits laser energy through a silicon die to melt the solder balls between the chip and the PCB. VCSEL heating systems can be used for both stationary and on-the-fly heating applications. In comparison to other solutions, VCSEL-based systems provide larger heating areas with higher power.

TRUMPF provides a testing lab for these potential applications at its Customer Application Center in Aachen, Germany. The company will also be exhibiting its solutions and products at the LASER World of Photonics in Munich, at booth 341 in Hall A6.

Ralph Gudde, VP Marketing and Sales, TRUMPF Photonic Components, explained, “It is great to see that with our unique VCSEL heating modules, electronics manufacturing can also benefit. The compact design and its homogeneous heating patterns lead to better process control and higher product quality. At the same time, it reduces the footprint of the assembly production line—in the case of LAB, by up to 30 percent.”

Image Source: TRUMPF

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe