Smart Solutions for Manufacturers

Smart factories will change operations and can transform products’ manufacturing due to their efficiency, competitiveness, and sustainability. Different Taiwanese manufacturers are implementing smart factories. A key sales engineer at Yeong Chin Machinery Industries Co, Ltd (YCM), a leading Machine Tool manufacturer in Taiwan, Hank Wu, explains some of YCM’s most pertinent smart manufacturing offerings.

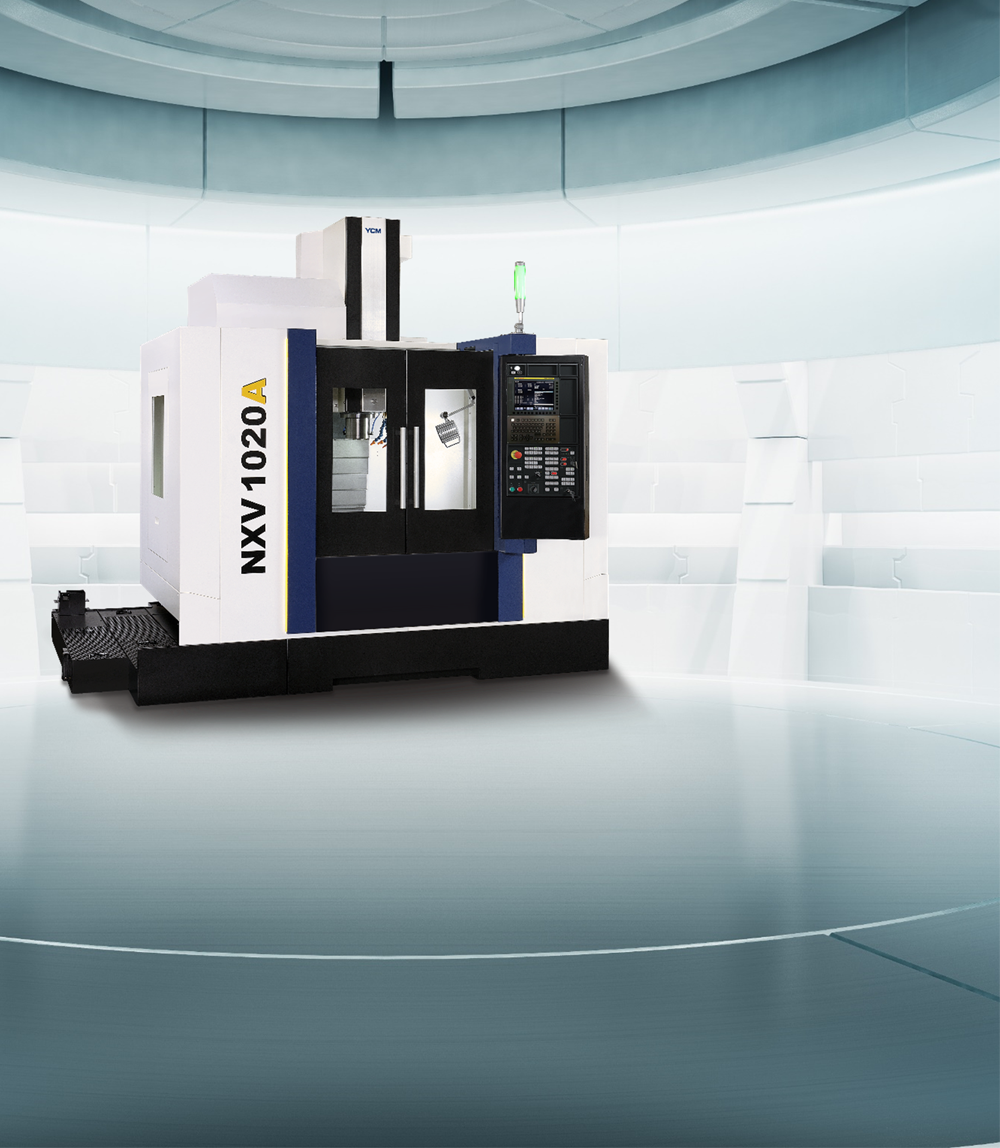

Founded in 1954, YCM specializes in machine tool manufacturing. YCM machine tools have been recognized worldwide for superior precision, outstanding rigidity, and exceptional reliability. With 68 years of machine tool manufacturing experience, the company has established a strong foundation in the field of machinery. It boasts a 164,160 m² factory area and main facilities including a foundry, machine shop, assembly plants, a warehouse for packaging, R&D, a tech center, an application center, and MIS.

With more than 70 different product models, including its main offerings of Vertical Machining Centers, Horizontal Machining Centers, Double Column Machining Centers, 5-Axis Vertical Machining Centers, and CNC Turning Centers, it also has CE and certifications for ISO 9001, ISO 14001, and AS 9100:2016.

The company has almost 70 years of experience making machine tools, and its YCMPS product model promises ‘sustainable development’, allowing YCM to become the best machine tool manufacturer in the world. YCMPS, based on the Toyota Production System (TPS) and lean management concepts, is motivated to produce equipment from metal casting to machining, assembly, quality control, packaging, and all the way to shipping.

Hank Wu, Yeong Chin Machinery Industries Co, Ltd (YCM)

YCM aims at smart manufacturing

The coronavirus (COVID-19) outbreak has already led to a major health crisis in several countries and major disruptions in the global economy. It is expected to cause a major reshuffling of the global production network. As a result, the pandemic is speeding up the adoption of automation and localization of production.

However, this pandemic is both a challenge and a turning point. Many companies are realizing how critical digital transformation is, especially with the rapid evolution of technologies such as Artificial Intelligence (AI), Big Data, Cloud Computing, the Internet of Things (IoT), and 5G.

Based on the principle of Toyota Production System (TPS) and lean management concepts, YCM provides innovative smart manufacturing solutions, enabling customers to adopt smart automation, smart machines, and smart management, allowing optimized production and efficiency, resulting in higher profitability.

Smart automation

By integrating industrial robots, intelligent machine tools, automatic measurement, statistical analysis, and central control systems, YCM is capable of providing automated solutions designed to improve production output with less manpower and facilitate improved collaboration between humans and machines.

NFX 400A High Performance 5-Axis Machining Center for flexible batch production

Smart machines

Another key element of YCM’s Smart Manufacturing solutions is smart machines. YCM introduced its own intelligent HMI iCube with an intuitive and user-friendly graphical design interface to add intelligent functionality to the standard features of Fanuc, Siemens, and Heidenhain controllers, providing customers with an enhanced and efficient operating experience.

The smart functions are embedded in the software for YCM machines to allow machines to rough machine faster while providing improved profile accuracy during the finishing process. YCM also provides value-added analysis of the machining process to optimize the machining parameters to achieve faster machining with better surface finish and tool life.

NH 500A High Speed Horizontal Machining Center for mass production

Smart management

Plant managers and owners can smartly manage their shops by applying DZ Connect. This system will connect all your equipment and provide real-time analysis of live data from the production environment.

The system gathers information on real-time operations and acquires data including equipment utilization and overall equipment effectiveness (OEE) rates; this enables managers to monitor and manage entire factories, instantly check the status of production, quickly identify and eliminate bottlenecks in the production process, and optimize production for maximum efficiency.

Smart Machines iCube

Develop customization and create differentiation

In today’s manufacturing world, there is an increasingly complex competition in the global market. Companies can no longer afford to compete based on pricing or cost strategy; they also need to consider how to improve their products and services in terms of value creation, customization, and differentiation. For this reason, YCM is dedicated to developing technology and equipment to help customers continuously improve their competitiveness and achieve sustainable growth.

By adding value through advanced applications and intelligent solutions, we can offer total and customized solutions to end-users based on their requirements through research and planning from customer situations.

As companies are now moving towards upscale production, the challenges ahead will be increasing productivity with limited resources, especially skilled labor. YCM is dedicated to developing technology and equipment to help customers continuously improve their competitiveness and achieve sustainable growth.

UV650-FlexCell

Equipped with a robot, the flexible manufacturing cell offers automatic side loading and unloading from part storage to the machine. It is ideal for shops that don’t have a lot of space but want maximum productivity right out of the box. Thanks to the flexible design, the part storage, drawer unit, automatic measuring system, and more can be adjusted in response to changing demand patterns, providing excellent flexibility and practical value that is suitable for various types of machines.

The advanced UV650 5-axis vertical machining center provides excellent cutting performance and high accuracy for simultaneous 5-axis applications with just one setup. Designed to reduce part handling, setup, and overall lead-time, while improving part quality, precision, and surface finish of complex shapes and contours required for multiple industries such as job shop, medical, aerospace, and die & mold.

Image Source: Yeong Chin Machinery Industries Co, Ltd

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe