Presenting Machine Tool Trends

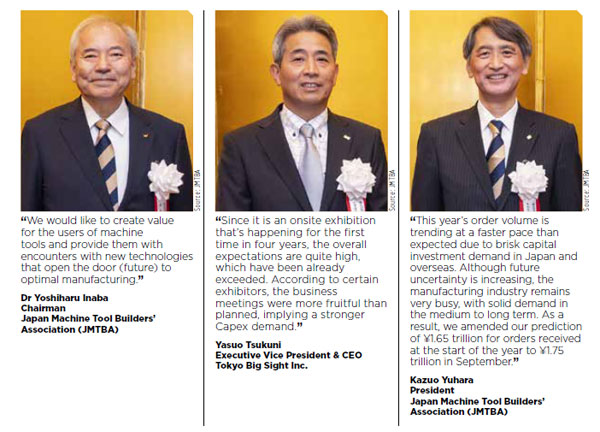

World-renowned JIMTOF has a 50-year history of being held biennially. However, the unprecedented turn of events due to the advent of the pandemic disrupted its otherwise prompt schedule, leading to the postponement of the show by four years. On the return of the much-awaited machine tool trade fair that holds a record for setting a perfect stage for exhibitors and visitors to actively engage in business negotiations and information exchanges, Dr Yoshiharu Inaba, Chairman, Japan Machine Tool Builders’ Association (JMTBA), stated, “JIMTOF, which was first held in 1962, celebrated its 60th anniversary this year. I am very relieved to be able to hold a face-to-face meeting for the first time in four years after overcoming the Corona wreck.”World-renowned JIMTOF has a 50-year history of being held biennially. However, the unprecedented turn of events due to the advent of the pandemic disrupted its otherwise prompt schedule, leading to the postponement of the show by four years. On the return of the much-awaited machine tool trade fair that holds a record for setting a perfect stage for exhibitors and visitors to actively engage in business negotiations and information exchanges, Dr Yoshiharu Inaba, Chairman, Japan Machine Tool Builders’ Association (JMTBA), stated, “JIMTOF, which was first held in 1962, celebrated its 60th anniversary this year. I am very relieved to be able to hold a face-to-face meeting for the first time in four years after overcoming the Corona wreck.”

Echoing similar sentiments, Yasuo Tsukuni, Executive Vice President & CEO, Tokyo Big Sight Inc., added, “Since it is an onsite exhibition that’s happening for the first time in four years, the overall expectations are quite high, which have already been exceeded. According to certain exhibitors, the business meetings were more fruitful than planned, implying a stronger Capex demand.”

With the completion of the South Exhibition Hall in 2019, JIMTOF 2022 took up the entire Tokyo Big Sight building with 1,086 companies/exhibitors and 5,619 booths, making it the largest ever. During the six-day event, 1,14,158 visitors attended, including 4,686 overseas guests.

Driven by the right approach

In light of the theme of the exhibition, ‘The Present and Future of Cutting-Edge Manufacturing: Machine Tools and Smart Factories’, Dr Inaba asserted, “We would like to create value for the users of machine tools and provide them with encounters with new technologies that open the door (future) to optimal manufacturing.”

JIMTOF 2022 occupied the entire Tokyo Big Sight building with 1,086 exhibitors and 5,619 booths, making it the largest ever event, garnering 1,14,158 visitors, and including 4,686 overseas guests over the six-day event.

The exhibition revolved around four key highlights:

Automation and labor-saving solutions: Many machine tool manufacturers displayed innovative products, technologies, and solutions concentrating on automation and labor-saving developed by linking machine tools, automatic measuring devices, collaborative robots, automatic guided vehicles, and so on.

Additive Manufacturing (AM): A dedicated ‘Additive Manufacturing Area’ was set up in the South Exhibiting Building, with an exhibition scale of 173 booths from 59 firms, making it one of the largest domestic AM shows, in addition to workshops held by exhibitors every day.

Response to the Sustainable Development Goals (SDGs): Set-up efficiency was targeted to be increased, and a showcase of Machine Tool industry efforts for the SDGs, such as enhancing the efficiency of equipment such as motors, was presented.

Disseminating Cutting-Edge Technology: The 19th International Machine Tool Engineers’ Conference, IMEC 2022, was held in the International Conference Hall, with lectures and presentations on cutting-edge research in machine tools from Japan and throughout the world.

Four fascinating sessions were presented under the overall theme of ‘Challenges for the Era of Great Change’, including ‘Trends in the Manufacturing industry toward Green Transformation’ and ‘Manufacturing Sites Changing with Digital Transformation’.

Japanese manufacturing and machine tool industry

Speaking about changes in macro indicators and future prospects, Kazuo Yuhara, President, Japan Machine Tool Builders’ Association (JMTBA), stated, “Looking at the quarterly change in Japan’s real GDP growth rate from the previous quarter, the most recent second quarter of FY2022 is up by 0.9 percent, and despite the impact of high resource prices, it is recovering moderately as the recovery from the Corona disaster and the removal of restrictions on movement progress.” He also claimed that, while advanced countries are likely to decelerate across the board, Japan is expected to develop stably at +1.6 percent in 2023, according to the IMF’s forecast.Citing green shoots of recovery and the future outlook, Yuhara added, “This year’s order volume is trending at a faster pace than expected due to brisk capital investment demand in Japan and overseas. Although future uncertainty is increasing due to rising inflation, interest rate hikes, and energy problems, especially in Europe and the US, the Manufacturing industry remains very busy, with solid demand in the medium to long term. As a result, we amended our prediction of ¥1.65 trillion for orders received at the start of the year to ¥1.75 trillion in September.”

Best of the best at the display

Showcasing Robotic Arm, LM Guide (Linear Motion Guide), and PPR Pick and Place Robot, Arun Sharma, Assistant Branch Manager - Delhi Branch, THK India Pvt Ltd, also provided an update on OMNIedge, a ready-to-use IoT solution developed for the Industrial Machine Tool segment, and stated, “It tells you about the health of your machine even from remote areas, so you don’t have to place maintenance personnel nearby.”

Urs Birri, Area Sales Manager Asia/Oceania, REGO-FIX AG, explained what powRgrip PGU 9500 is at JIMTOF 2022, “It is a highly accurate tool clamping system for very fast tool clamping. It provides high transmissible power and rigidity with a vibration-dampening system. It is a terrific technology that is being used in a variety of settings.”

When compared to the same period last year, the total amount of Japan Machine tool orders received from January to September this year increased by 21.3 percent to ¥1,343.8 billion, the second highest in history.

Presenting the Muratec MT200, Rishi Kapoor, AVP and General Manager, Meiban Engineering Technologies Pvt Ltd, said, “This machine is a multitasking machine and offers process integration. Turning and Turn Mill operations can be performed on the same machine. It is available with two/three turrets and two spindles. All of the turrets include the Y-axis to perform odd operations. This machine is designed for small- to medium-batch size components with quick changeover for automotive and non-automotive applications.”

Jake Farragher, General Manager - Asia, ANCA CNC Machines, unveiled MX-7 Ultra and explained, “The MX-7 Ultra produces high-quality End Mills with a very fine finish. We have a new, unique control system that lets us regulate the machine down to the nanometer, which translates to exceptionally high-precision tools. It has an integrated laser for compensation, a six-wheel pack changer, and many other applications.”

Shinji Yamamoto, Senior Manager Director, Fanuc, talked about its new large material handling robot, M-1000iA, at the event stall: “This machine has a wrist payload of 1,000 kg and features a serial link mechanism, allowing for a wider range of motion in both vertical and longitudinal directions and the arm to stand upright and rotate backward. This capability provides the users with extended versatility across a wide range of handling applications, allowing them to automate production lines and improve productivity in their applications.”

Tomohiro Oshikiri, General Manager, Asia Sales, Makino Milling Machine Co., Ltd, on its latest a900Z Horizontal five-axis machine center at JIMTOF 2022, commented, “With an 800 mm part size, a 1,250 mm maximum walkthrough size, and payload weights up to 1,200 kg, this machine is a one-of-a-kind configuration of a five-axis machine with a tilt axis.”

The European Association of Machine Tool Industries and related Manufacturing Technologies, CECIMO, also marked its presence at JIMTOF 2022. Filip Geerts, Director General, CECIMO, during a dialogue at the exhibition, pointed out, “The European Machine Tool industry experienced a significant uptick immediately following the COVID-19 breakout. In 2021 and 2022, we had a lot of production, and we still anticipate a 10 percent rise. But it is also due to a significant backlog, as there were numerous supply chain issues at the same time. As a result, I must say that our outlook for 2023 is more optimistic.”

Offering novel solutions, Garven Hou, Industrial Partnerships/Key Account Manager APAC, Blaser Swisslube Asia Ltd, commented, “We have new products for Japan that need high-flash point regulations, and we also have some Neat Oils that resemble water but are actually based on modern technology. A Vasco 6000, which is excellent for hard steel and particularly for grinding applications, is one of our newer products. Additionally, we now offer the B-Cool MC 610, which may be used with a variety of materials, both when turning and milling.”

JIMTOF 2018 drew a record 1,53,103 visitors, including 12,934 overseas visitors. The highly anticipated next edition is scheduled for November 5-10, 2024, at Tokyo Big Sight.

Geared up for the next edition

The recent edition of JIMTOF set the tone for the much-anticipated post-pandemic industrial revolution and economic boost to Japan. With renewed vitality, the next edition in 2024, set to be held at Tokyo Big Sight from November 5-10, is much awaited by the industry and expected to outperform its 2018 edition, which drew a record 1,53,103 visitors, including 12,934 overseas guests.

MURALI SUNDARAM

CorrespondentMagic Wand Media In

cmurali.sundaram@magicwandmedia.in

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe