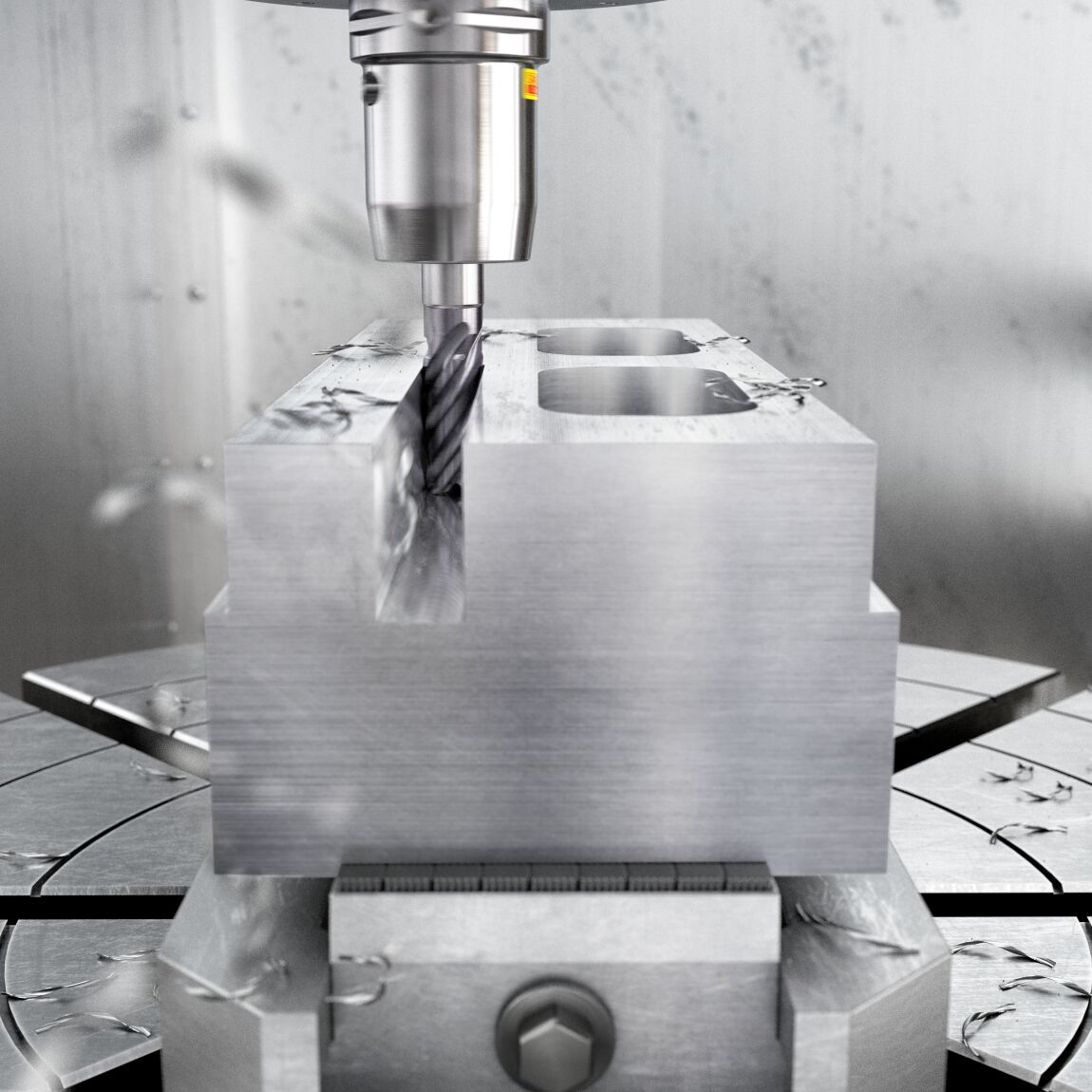

Sandvik Coromant Unveils New Grades for CoroMill® Plura HD Solid End Mills for Heavy-duty Roughing

Sandviken, Sweden – Sandvik Coromant, a cutting tool specialist, expands its offer of CoroMill® Plura HD solid end mills for heavy-duty roughing in steel and stainless steel with two new grades. This new generation of grades features the unique Zertivo™ 2.0 coating, which combines world-class productivity with an exceptional metal removal rate and the highest possible process security. CoroMill® Plura HD is the company’s first choice optimized solution for heavy-duty applications up to 2×D in steel and stainless steel (ISO P and ISO M), offering safe and efficient solid end milling. Thanks to the new Zertivo™ 2.0 coated grades, tool life, process security, and productivity are improved even further.

The new grades allow for 30 percent higher cutting speed recommendations in primary application areas (ISO P and ISO M), as well as secondary materials (ISO K and ISO S), due to their optimized flute shape, which provides effective chip evacuation. The grades designed for stainless steel machining come in two variants: one with internal coolant for improved temperature control and chip flow, and one without internal coolant. The standard assortment offers diameters from 2–25 mm, a 2×D depth of cut, 4 to 5 teeth, and a ramping angle at 5° or 7°. Tailor Made® options are available within the Customized solutions range.

The new grades allow for 30 percent higher cutting speed recommendations in primary application areas (ISO P and ISO M), as well as secondary materials (ISO K and ISO S), due to their optimized flute shape, which provides effective chip evacuation. The grades designed for stainless steel machining come in two variants: one with internal coolant for improved temperature control and chip flow, and one without internal coolant. The standard assortment offers diameters from 2–25 mm, a 2×D depth of cut, 4 to 5 teeth, and a ramping angle at 5° or 7°. Tailor Made® options are available within the Customized solutions range.

Antti Wikström, Global Product Manager, Solid End Mills, Sandvik Coromant, said, “With Zertivo™ 2.0, we apply our comprehensive knowledge in coating technologies to our solid round tools. This gives us an opportunity to offer unique, custom-made coatings that will handle our customers’ machining challenges with superior performance and tooling efficiency.“

Image Source: Sandvik Coromant

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe