Sandvik Coromant’s M5F90 Face-Milling Optimize Battery Tray Machining

Automotive original equipment manufacturers (OEMs) are getting more involved in battery cell production, which is moving physically closer to vehicle assembly plants. McKinsey & Company reports that battery technology, durability, and performance will be key differentiators that set OEMs apart. Here, Fernando Oliveira, Global Manager for Automotive Aluminum at metal cutting specialist Sandvik Coromant, explains how its new concept M5F90 face-milling cutter could be crucial for helping OEMs get ahead of their peers.

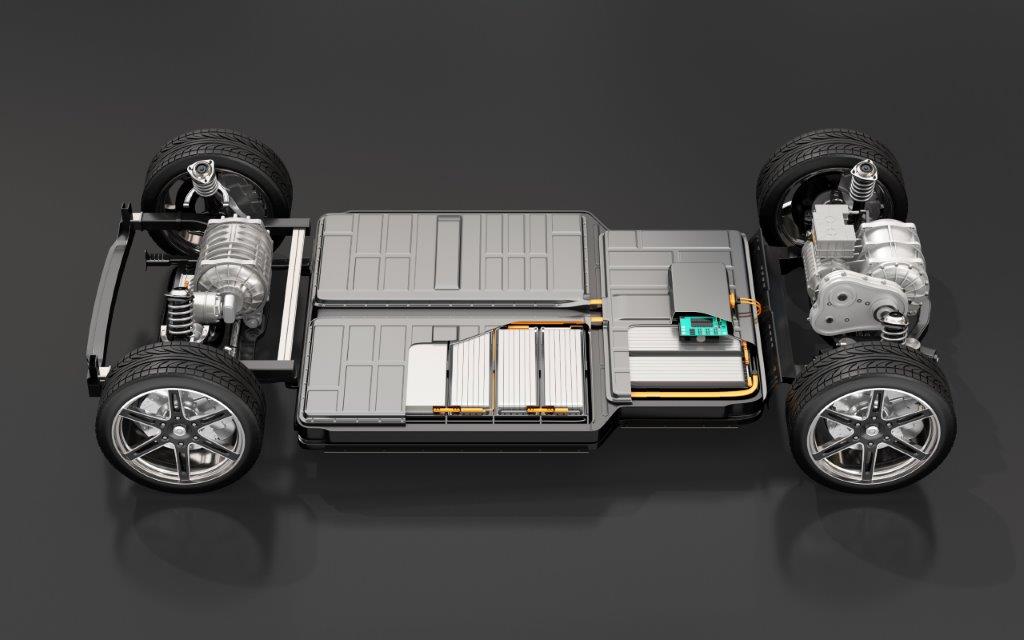

Battery systems will continue to evolve over the coming years, and new developments and shapes will be required. For OEMs, this will entail producing near-net-shaped battery system parts based on more complex designs. Machining these designs will require efficient and lighter-cutting tools to minimize impact on the machine tool and ensure the component stays in shape.

The role of OEMs is also evolving as they get more involved in battery production, which McKinsey & Company attributes to “the backward integration of OEMs from packs and modules up to cell production.” At the same time, the race is on to build lighter and more efficient electric vehicles (EVs) that travel longer distances with a maximized vehicle range per charge.

Furthermore, manufacturers must produce these more-complex components to the highest quality and with high productivity. How can manufacturers achieve this while maintaining a low cost-per-component? The answer lies in more efficient cutting tools, which have good accessibility and are as light as possible to allow quick tool changes.

Reducing CO2 emissions

Manufacturers are turning to ‘lightweighting’, which entails building cars and trucks that are less heavy, as a way to achieve better fuel efficiency and handling.

Another McKinsey & Company study, Lightweight, Heavy Impact, calculates that “Lightweight measures can help reduce CO2 emissions to a certain extent (approximately 0.08 g CO2 reduction per kilogram saved).” It concludes that “If an OEM manages to reduce the vehicle weight by 100 kg, it saves approximately 8.5 g CO2 per 100 km.”

As one of the lightest metals in the world, aluminum is an established lightweighting solution. Aluminum is almost three-times lighter than iron and, although of lower strength than iron, is still very strong and corrosion resistant. From a design engineering perspective, it has been found that placing conventional cast iron parts with aluminum alloys can reduce the overall weight of the engine block by up to 40–55%.

A further advantage of aluminum is that it is very recyclable and can be melted and reused without any harm or change to its mechanical properties. In fact, approximately 75% of all aluminum ever produced is still in use today, which is testament to the material’s usefulness in OEMs’ sustainability strategies.

A further advantage of aluminum is that it is very recyclable and can be melted and reused without any harm or change to its mechanical properties. In fact, approximately 75% of all aluminum ever produced is still in use today, which is testament to the material’s usefulness in OEMs’ sustainability strategies.

Smaller faces

The power train of a European passenger car typically contains around 80 kilograms of aluminum, which means these parts—the engine, gear box, suspension parts, and housings—are an obvious area of interest for light weighting measures. Aluminum may also be used in the batteries themselves: the EU-China Energy Cooperation Platform (ECECP) recommends aluminum-air (AI-air) batteries as an “l‘inexpensive, light, and powerful’ alternative to lithium-ion (Li-ion) batteries.

Here, let’s focus on aluminum battery racks. These components generally have smaller faces with more threads, holes, and other features. Another important consideration is electric battery racks for trucks, specifically larger models driven away from built-up areas, which measure up-to two meters in length.

Battery racks require an assortment of machine tools and applications like milling, rimming, and more. Yet even larger battery racks don’t require large tools and are, instead, made up of smaller faces with more features, threads, and holes. Therefore, they require shoulder and face milling tools or reamers that can produce components to the required quality and tolerances.

Eliminating vibrations

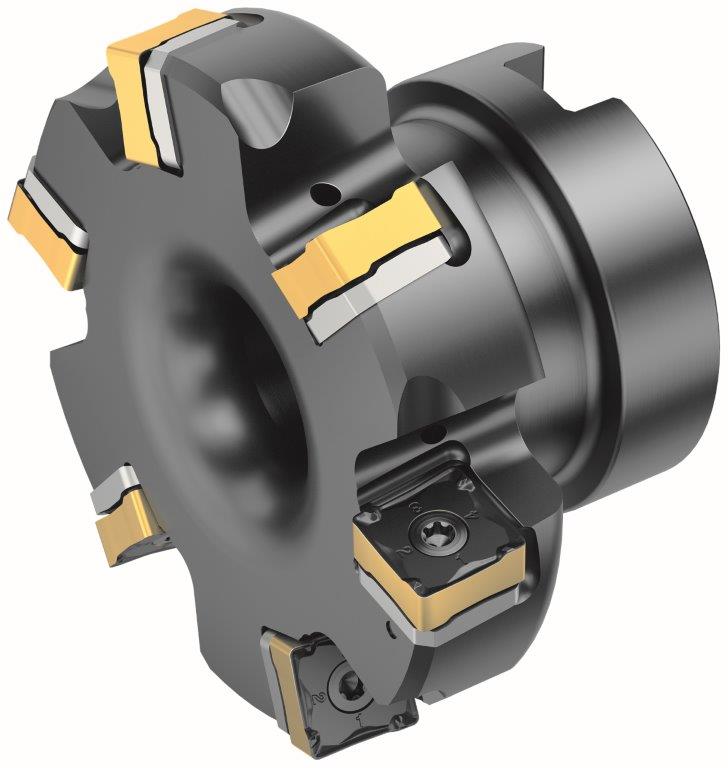

For machining battery racks, Sandvik Coromant recommends using its M5 family of dedicated automotive aluminum milling cutters, including the M5F90 face-milling cutter designed to machine parts without burring, scratching, or chipping. The cutter is dedicated to machining thin-wall aluminum parts, and to achieve this, it is equipped with a smaller cutter body of 25-80 mm or 0.98-3.15 inch in diameter. The M5F90 also contains brazed Polycrystalline Diamond (PCD) tips, which require no adjustment and secure very reduced runouts. This enables high feed rates while also eliminating cutting vibrations.

In one instance, the M5F90 was used to machine an aluminum battery tray. This was an ideal application for the new concept face-milling cutter because the application required that the tool be used to clean surfaces in the first machining stage of the newly-cast aluminum part in a single operation without burring.

Its dimensions were approximately 980 x 600 x 130 millimeters (mm). Overall, 48 tools were used to machine the component, including solid carbide drills, solid carbide end mills, high-speed steel (HSS) taps, brazed PCD reamers, brazed PCD milling cutters, and, lastly, the M5F90 cutter. The aluminum component was machined in a 5-axis machining center equipped with a HSK 63 high-speed tool holder.

The M5F90’s brazed PCD inserts have stepwise cutting edges in both senses, radially and tangentially. This characteristic lowers the power consumption, allowing the machine to run with higher cutting parameters, which eliminates burrs and reduces vibrations during machining. The latter advantage, in particular, helps give reliable performance with improved tool life and increases the number of components machined.

In the end, the battery tray machining application demonstrated a key advantage of the M5F90. Specifically, that it enables roughing and finishing in a single operation, thus saving time. This was demonstrated in the machining of the aluminum battery tray; the component was machined in 20.3 minutes. With this enhanced tool performance, OEMs can get more involved in producing battery systems while setting themselves apart from competitors.

Image Source: Sandvik Coromant

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe