DEVELOPING SUSTAINABLE MACHINE TOOLS

The machine tool industry is rethinking its approach to sustainability. While upgrading technology, cutting costs, and reusing materials, remanufacturing offers a way to restore machines to as-good-as-new condition. Here’s knowing how Grind Master is applying this philosophy and creating from basic fundamental principles a method to deliver the desired result with consistency.

As a machine manufacturing company with a vision to be Net ZERO by 2030, Grind Master faces a unique challenge. Manufacturing, by its nature, consumes natural resources such as steel and requires significant energy to convert these materials into machines. This process leads to unavoidable emissions. That is why we must find ways to minimize these emissions and offset what cannot be avoided. At the end of a machine’s life, waste generation completes a classic linear model of resource usage. We are taking steps to offset this impact—through solar energy adoption, afforestation projects, and improved energy efficiency wherever possible. But the bigger question remains: can we fundamentally change the way we do business?

Ajay Phatak, our mentor for the Sustainability Mission, challenged our team to develop ideas and solutions to address this critical issue. We explored and brainstormed various business models adopted by other industries, assessing their potential fit for our field of custom-built specialized machinery for metal finishing. Around 90 percent of our projects are special-purpose turnkey solutions with a high degree of customization. With over 60 percent of our output exported to markets including China, Southeast Asia, North America, and Europe, our technology serves a niche segment—and we are widely recognized as experts in our domain.

By applying the fundamentals of globally successful REMAN programs—such as those pioneered by Caterpillar and Cummins—to the specialized machine tools business, we developed our own Grind Master REMAN program. This article offers insights into how REMAN principles can be adapted to the Machine Tool industry. While not a unique methodology, it represents one of several evolving approaches to sustainable manufacturing. Remanufacturing is defined as ‘the rebuilding of a product to the specifications of the original manufactured product using a combination of reused, repaired, and new parts’.

A machine tool is made up of a diverse range of materials and components:

- Steel and aluminum – in the form of castings and fabrications.

- Active elements such as motors, gearboxes, and cylinders, each composed of various materials.

- Electronics including controllers and HMI (Human-Machine Interface) elements.

- Electrical and pneumatic interfacing components, among others.

While most of these elements have a long lifespan if properly maintained, the overall ‘life’ of a machine tool is typically considered to be between 5 and 10 years. Why is that the case? The key reasons include:

Technology Obsolescence – This is especially true about Control Systems that go through substantial changes

in electronics over a period of 5-10 years.

Product Obsolescence – This is especially true for custom-built specialized machines.

Sub Optimal Performance – Mainly due to specific elements degrading over time.

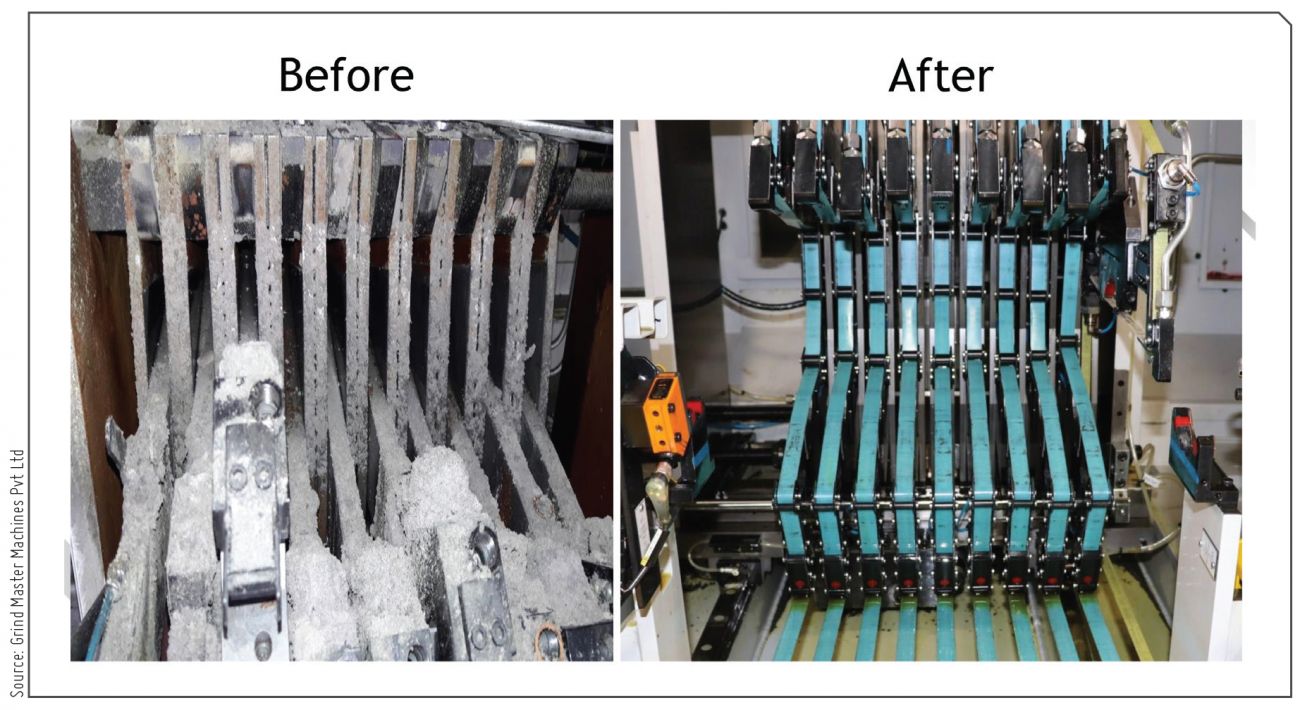

A common approach in the Manufacturing industry to address such issues is to refurbish or recondition machines. This work is often carried out by in-house Maintenance Departments or sometimes by professional facilities. Reconditioning normally is an ‘ONSITE Activity’ done at the site where the machine is being used.

It basically involves cleaning, repairs, or replacements of worn out or damaged parts, oiling and fastening to make them functional. Sometimes the machine is given an aesthetic facelift with a fresh coat of paint, while at other times certain control elements may be replaced. There are some basic limitations in the ‘REFURBISH’ process when applied to machine tools. It must be performed using the resources available at the site, allows only a limited scope for upgrades or modifications, and typically extends machine life by just a few years—usually until the next scheduled refurbishment.

The REFURBISHING process does not address the machine tool obsolescence due to the first limitation, and only partially addresses reasons second and third.

A REFURBISHED machine does not match the performance or the lifespan of a new machine. Over time, its mechanisms

continue to deteriorate, leading to more frequent and severe failures. This causes uncertainty which is unaffordable in mass manufacturing.

REMANUFACTURING (REMAN) is the Next Level

Remanufacturing is now added in core business strategy of many leading industries including Caterpillar and Cummins, both of whom as business partners continue to inspire us. It provides a ‘win-win deal’.

Remanufactured products are:

As good as new – backed by warranty and offering the same expected life as a new product.

Contemporary – upgraded with the latest relevant technologies.

Economical – providing substantial cost savings for the end user.

Sustainable – reusing a significant percentage of original

raw materials.

REMAN is fundamentally different from both manufacturing and refurbishing. It combines the scalability and consistency of manufacturing with the resource efficiency of reusing materials. Companies like Caterpillar and Cummins have proven its value—Caterpillar REMAN, for example, operates more than 8 facilities worldwide, employs over 3,600 people, and remanufactures more than 8,000 different products.

|

REMAN is fundamentally different from both manufacturing and refurbishing. It combines the scalability and consistency of manufacturing with the resource efficiency of reusing materials. |

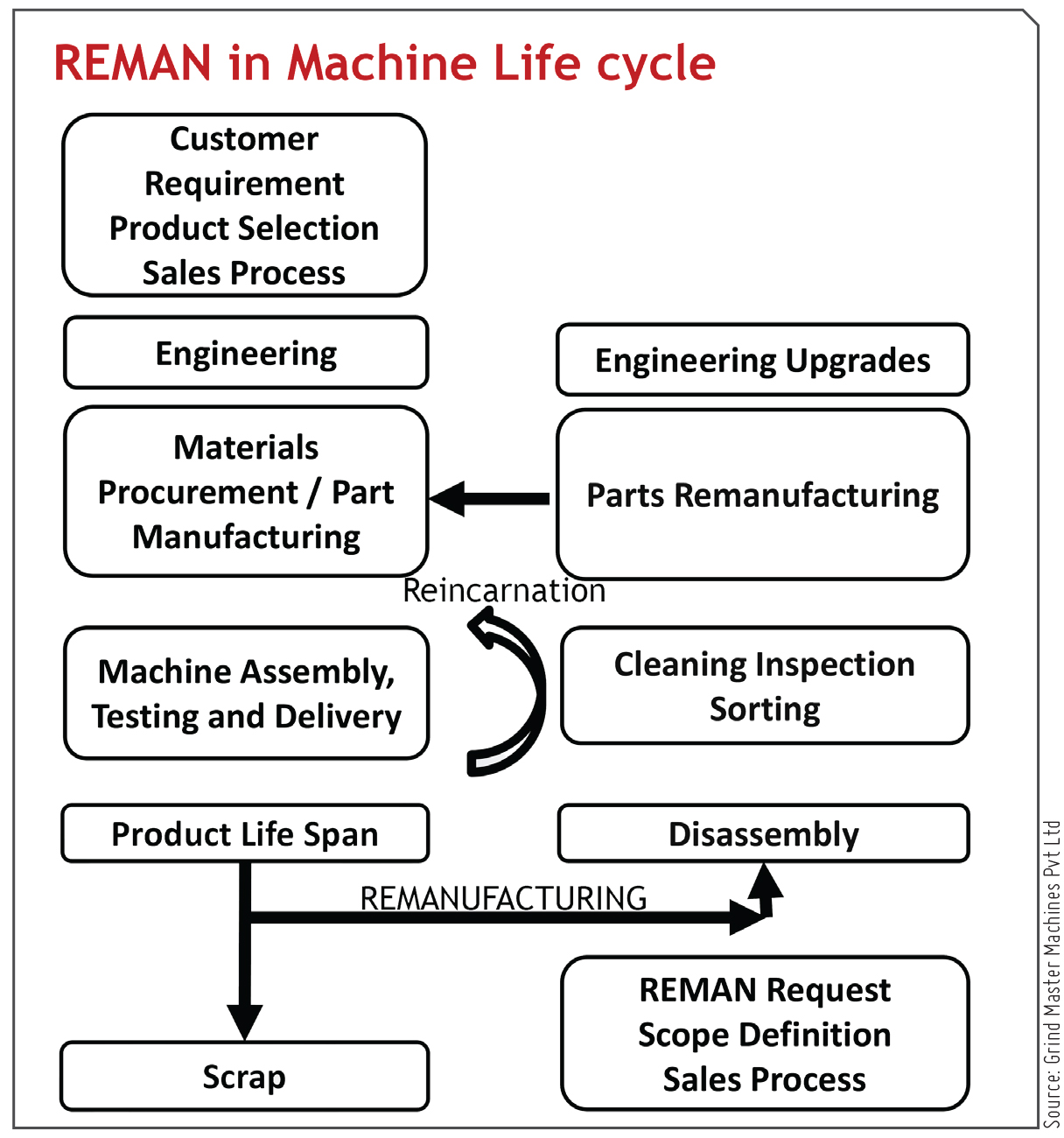

Grind Master has formed a cross functional team to apply the philosophy of REMANUFACTURING and create from basic fundamental principles a method — a system to deliver the desired result with consistency. This ‘Strategic and Systematic’ approach to REMAN has led us to formulate our own Phased project implementation plan.

As can be seen from the flowchart, a REMAN Machine undergoes the same Engineering Reviews, Part Quality Check Systems, Assembly and Testing, Delivery and Commissioning as a new machine. Major changes are made to the system in three functions:

- Conceptualization of Project – Scope

- Machine ‘Decommissioning’ and Shipment to OEM

- Disassembly and Material Utilization Analysis

Remanufactured Machine Delivers a Win–Win–Win

For the manufacturer:

- A machine restored to as-good-as-new condition—often with possible improvements and upgrades.

- Addition of new variants, optimized cycle times, and faster setup changes.

- Compliance with the latest IoT, safety, and EHS (environment, health, and safety) requirements.

- Integration of energy-efficient elements.

- Extended life of 8–10 years, backed by warranty.

- Immediate cost savings and excellent return on investment.

For the machine builder:

- Profitable, value-added business.

- Over 80% material reutilization (by weight).

For Both:

- Progress toward their sustainability goals.

Remanufacturing has thus proven to be a highly feasible business model for custom-built specialized machinery such as finishing machines. Integrating it as a core part of the business strategy can significantly advance the circular economy in capital goods including machinery.

|

Grind Master has formed a cross functional team to apply the philosophy of REMANUFACTURING and create from basic fundamental principles a method – a system to deliver the desired result with consistency. |

That said, there is still a long way to go in bringing about this transformation. It will require the willingness of machine tool manufacturers to explore and adopt the model, greater customer acceptance of remanufactured products, and the establishment of clear systems, methodologies, and industry-wide standards for remanufacturing.

With inputs from: Radhakrishna Barde, General Manager, Grind Master Machines Pvt Ltd and Ajay Phatak, Trustee for The Ecological Society and TERRE

|

Sameer Kelkar |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe