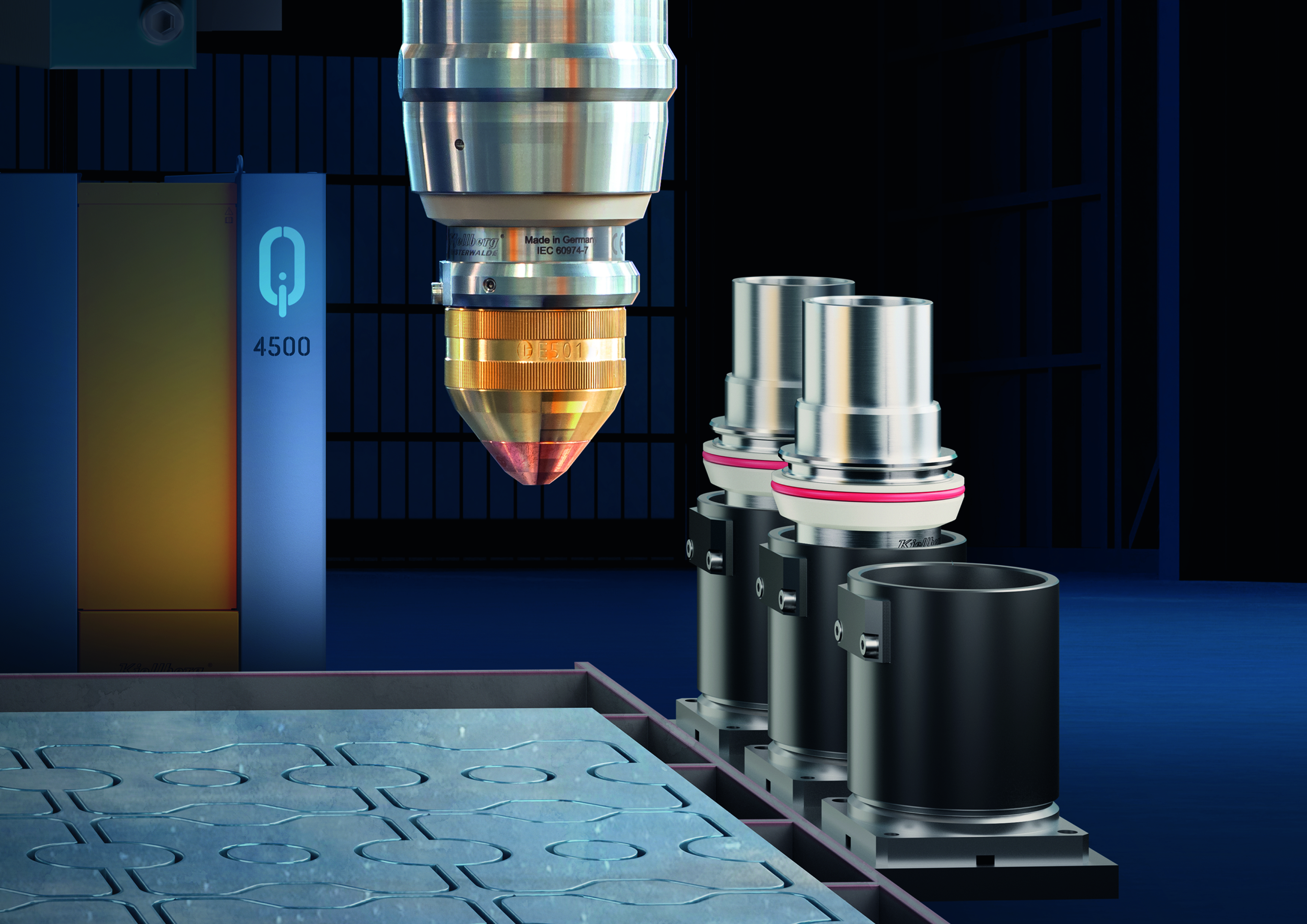

Kjellberg Continues to Innovate With the iQ-Series

The plasma cutting systems of the iQ-Series stand for proven cutting quality and advanced technology. They enable precise cutting up to 130 mm, exact contours and precise holes, bevel cutting, as well as versatile applications such as marking, notching or punching. The modular design of the iQ-Series allows flexible adjustment of cutting performance to meet growing production requirements. Digital condition monitoring guarantees maximum utilization of consumables while maintaining high cutting quality.

High cutting speeds ensure greater efficiency and low costs per meter cut. Automation capability and eService make these plasma cutting systems a future-proof solution.

In combination with the Q-Torch Auto Change System – a new solution for fast and precise tool changing – the automation in plasma cutting will be pushed to the next level. With this innovation, the torch heads are pneumatically coupled and uncoupled without applying any force. For customers, the results are unique: saving valuable machine time, preventing operating errors, and supporting unmanned plasma cutting.

The Q-Torch Auto Change System also enables easy adaptation to one’s production requirements, as the quantity of docking stations for the torch heads has no limits and can be chosen according to one’s needs.

Kjellberg Cutting and Welding India Pvt Ltd

www.kjellberg.de/home

Hall & Stall: 4/B-115

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe