Embracing a Transformative Approach

Paragon Medical – Southington leveraged ESPRIT CAM, which helped it reduce the time it took to program a 7-axis lathe from three days to one and offered many other benefits.

Paragon Medical – Southington, formerly known as Economy Spring & Stamping, is a manufacturer of precision and custom wire forms, metal stampings, coil springs, tubular components, and product assemblies. It serves the Medical, Pharmaceutical, Aerospace, and Industrial markets. To stay competitive, the company has invested in the latest manufacturing equipment, including two Citizen 7-axis Swiss-type turning centers boasting 400-watt L2000 laser cutting systems.

Complex parts, complex manufacturing

Complex parts, complex manufacturing

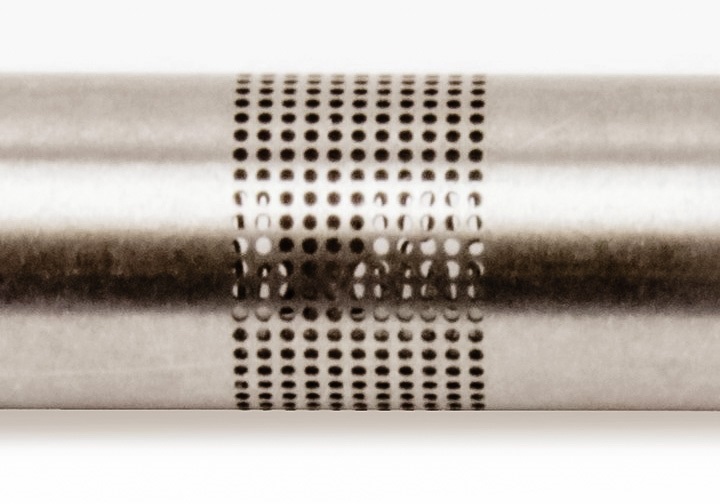

The company manufactures a wealth of complex parts, such as two concentric tubes used in the Medical industry for administering fluid to incisions. The outer tube requires a 0.172-inch outer diameter and a 0.158-inch inner diameter, while the inner tube requires a 0.152-inch outer diameter and a 0.128-inch inner diameter. The front end of the inner tube is marked by several intricate shapes, including two boot-shaped features precisely 180 degrees apart from each other. To make matters more complex, the inner tubes also require drilling of 22 0.007-inch diameter injection holes in a helical pattern. There’s also a 12-inch slot in the part that is longer than the total travel of the lathe.

Programmers at Paragon Medical – Southington previously programmed this and other similar parts using the machine control. They would enter many manual commands, including laser commands and commands to coordinate the operations of the two spindles. After completing the program, programmers would not be sure of accuracy or collisions until they ran the part for the first time.

Balancing operations between the machine’s two spindles was also difficult. For example, programmers had no way to determine whether it was efficient to perform turning and drilling on the main spindle and perform a secondary operation on the sub-spindle at the same time. If time is money, then these decisions were doubly important. One spindle often sat idle until the other finished its operation.

Finding solution

“We decided to switch to ESPRIT CAM software because it supported the latest machine tool features and its powerful simulation capabilities that enable us to optimize the program without taking up valuable machine time,” says Dale Akerley, Advanced Manufacturing Department Leader, Paragon Medical – Southington.

Akerley began programming the tubes with ESPRIT by importing the SolidWorks CAD file that was provided by the customer. Importing the part geometry saves time and minimizes errors by ensuring that the program matches the customer’s original vision. ESPRIT then analyzes the imported geometry and automatically recognizes all the features, such as the holes and boots mentioned earlier.

He selected each feature of the part and picked a tool to machine from a graphical representation of the Citizen Swiss lathe. The knowledge base, included with the software, automatically generates typical machining parameters such as cutting speed, feed rate, and depth of cut. Both the detailed features on the front end of the part and the holes were produced by the laser—which can produce nearly any geometric shape to an accuracy of 0.00001 inch. When the company first began using the laser, it wasn’t supported by any CAM software, so it required time-consuming manual programming.

Balancing operations between the machine’s two spindles was also difficult. Programmers had no way to determine whether it was efficient to perform turning and drilling on the main spindle and perform a secondary operation on the sub-spindle at the same time.

Benefits abound

ESPRIT sent a technician to Paragon Medical – Southington. The technician spent days working with Akerley to develop a post-processor that automatically generates the instructions needed to set up the laser and perform the machining operations. With the post-processor in place, Paragon Medical – Southington programmers treat the laser as if it were an ordinary cutting tool. ESPRIT then automatically generates the G-code instructions for the laser and metal cutting operations needed to produce the part.

Akerley then tentatively assigned the operations to spindles and simulated the complete machining operation, so he could visualize exactly how the operations were flowing and also determine if any time was being wasted.

Paragon Medical – Southington’s first laser Swiss machine, a Citizen L220 Type 8, was installed in 2016.

Development of laser cutting processes continues to open new avenues of business for the shop.

“We can reorder operations, move operations from one spindle to another and sync operations so they start at the same time with a few clicks of a mouse,” Akerley says. He used a regrip operation to move the stock from the main spindle to the sub-spindle so the 12-inch slot could be fully machined.

“We can reorder operations, move operations from one spindle to another and sync operations so they start at the same time with a few clicks of a mouse,” Akerley says. He used a regrip operation to move the stock from the main spindle to the sub-spindle so the 12-inch slot could be fully machined.

“Switching to ESPRIT reduced the time required to program these parts from about three days to one day, and we have achieved proportional time savings on a wide range of other parts,” he adds. “This represents a major time saving and the time required to test the program of the machine is also greatly reduced because simulation helps us nearly always get the program right the first time. We have also achieved significant cycle time reductions by identifying idle time during the simulation and modifying the program to make it more efficient. All in all, switching to ESPRIT has helped us significantly increase the efficiency of our machining options.”

Small holes cut on part with the L2000 laser cutting system.

Switching to ESPRIT reduced the time required to program complex parts from about three days to one day, and the company achieved proportional time savings on a wide range of other parts.

Source: ESPRIT

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe